EVCO EVXS815P9 Installer manual User Manual

Page 33

EVCO S.p.A.

EVSX815 | Installer manual ver. 1.3 | Code 144XS815E134

page 33 of 60

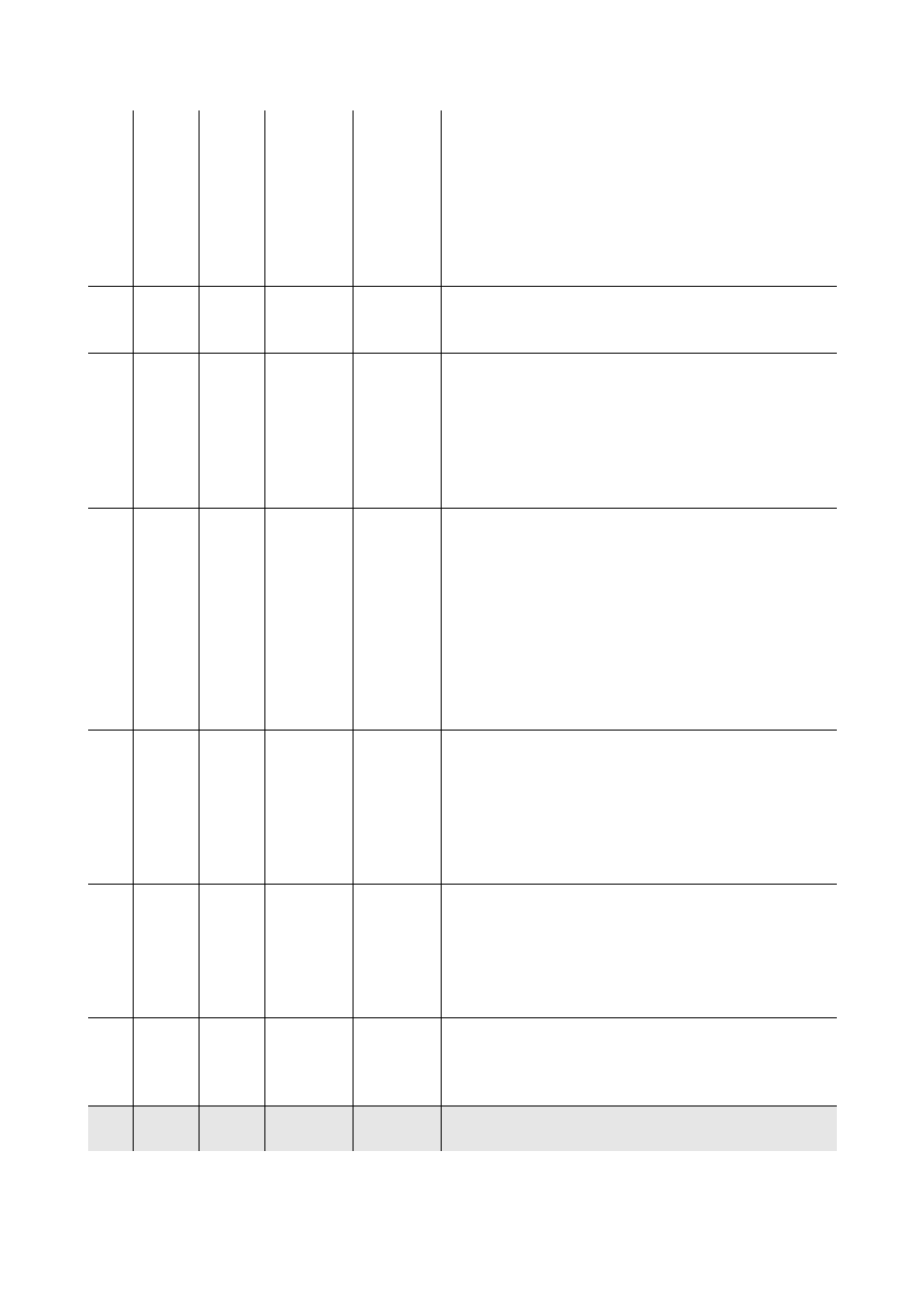

r17

0.0

99.0

°C/°F (1)

5.0

"temperature detected by the needle probe - cabinet

temperature" minimum difference such to consider the first

phase of the test to verify correct insertion of the needle

probe completed successfully (consider the difference

without sign)

0.0 = the test will not be performed (neither first or second

phase)

r18

1

99

s

60

duration of the second phase of the test for verification of

correct insertion of the needle probe

r19

0

1

- - - -

0

quick modification value during the "On" status before

starting the operating cycle

0 = work set-point during blast chilling or during deep

freezing

1 = blast chilling or deep freezing end temperature

r20

0

1

- - - -

1

memorisation of the quick modification value during the

"On" status before starting the operating cycle

0 = no (on start-up of the successive same cycle, the

values established with parameters r7 and r3 or

those establishes with r4 and r8 will be re-proposed)

1 = yes (on start-up of the successive same cycle the

rapidly modified values will be re-proposed before

starting the previous same cycle)

r21

0

1

- - - -

1

modality the operating cycle is started time controller rather

than time controlled

0 = automatic (or through the test regarding correct

insertion of the needle probe)

1 = by hand (or pressing and releasing the BLAST

CHILLING or DEEP FREEZING key)

r22

0

1

- - - -

0

modality to start pre-cooling

0 = automatic (or pressing the BLAST CHILLING key 1 s)

1 = both automatic (or passing from the "stand-by"

status to the "on", then switching on the device) and

by hand (or pressing the BLAST CHILLING key 1 s)

r23

0

50

s

2

duration of the buzzer activation to signal the verification

test for the correct insertion of the needle probe will not

have been completed successfully

Par.

Min.

Max.

Unit

Default

Compressor protections