Digilent DIO2 User Manual

Page 12

Digilab DIO2 Reference Manual

Digilent, Inc.

www.digilentinc.com

page 12 of 19

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

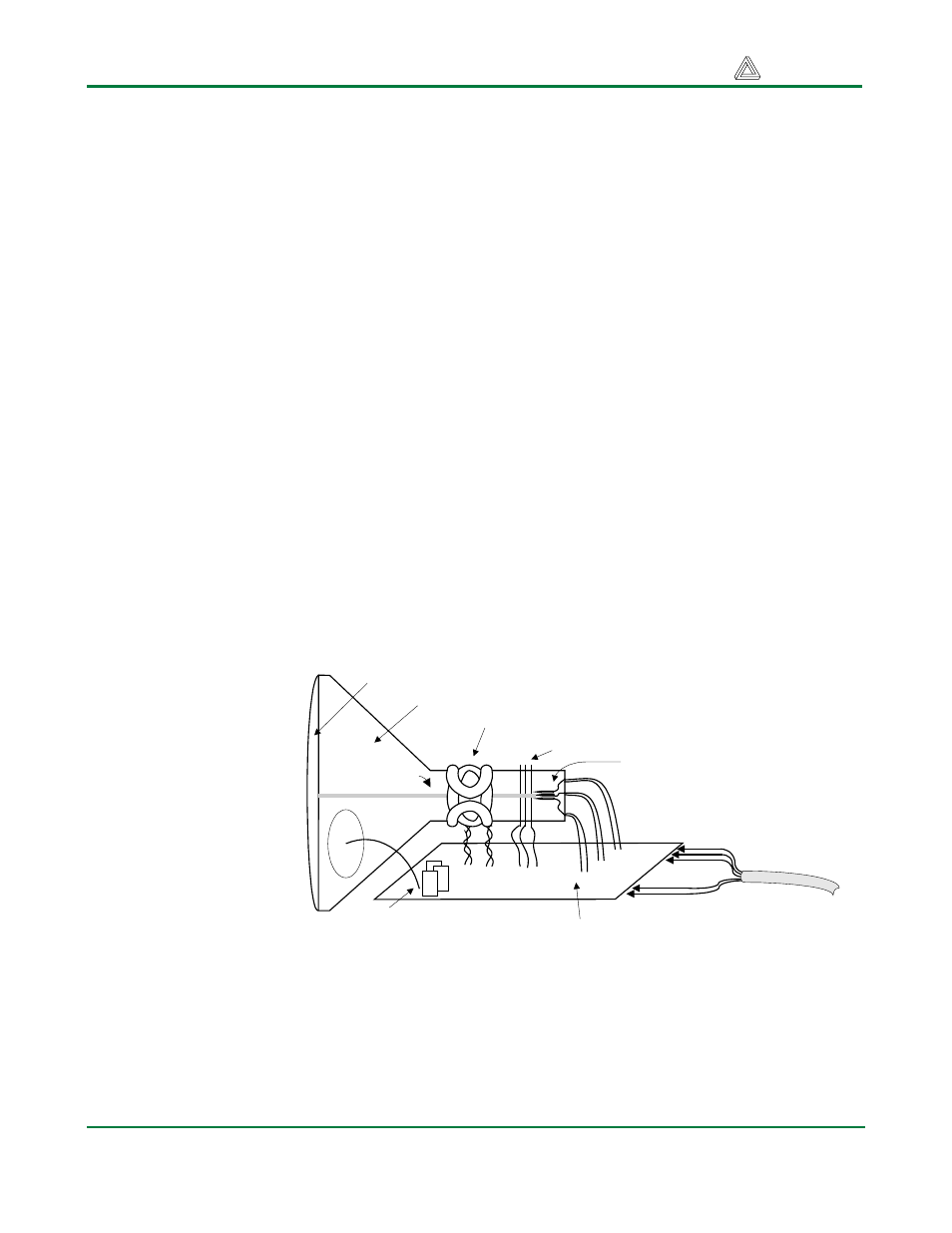

LCD displays have evolved to use the same signal timings as CRT displays (so the “signals”

discussion below pertains to both CRTs and LCDs).

CRT displays use electron beams (one for red, one for blue and one for green) to illuminate phosphor

that coats the inner side of the display end of a cathode ray tube (see drawing below). Electron beams

emanate from “electron guns”, which are a finely pointed, heated cathodes placed in close proximity to

a positively charged annular plate called a “grid”. The electrostatic force imposed by the grid pulls

away rays of energized electrons as current flows into the cathodes. These particle rays are initially

accelerated towards the grid, but they soon fall under the influence of the much larger electrostatic

force that results from the entire phosphor coated display surface of the CRT being charged to 20kV

(or more). The rays are focused to a fine beam as they pass through the center of the grids, and then

they accelerate to impact on the phosphor coated display surface. The phosphor surface glows brightly

at the impact point, and the phosphor continues to glow for several hundred microseconds after the

beam is removed. The larger the current fed into the cathode, the brighter the phosphor will glow.

Between the grid and the display surface, the beam passes through the neck of the CRT where two

coils of wire produce orthogonal electromagnetic fields. Because cathode rays are composed of

charged particles (electrons), they can be bent by these magnetic fields. Current waveforms are passed

through the coils to produce magnetic fields that cause the electron beams to transverse the display

surface in a “raster” pattern, horizontally from left to right and vertically from top to bottom.

Information is only displayed when the beam is moving in the “forward” direction (left to right and top

to bottom), and not during the time the beam is reset back to the left or top edge of the display. Much

of the potential display time is therefore lost in “blanking” periods when the beam is reset and

stabilized to begin a new horizontal or vertical display pass.

The size of the beams,

the frequency at which

the beam can be traced

across the display, and

the frequency at which

the electron beam can be

modulated determine the

display resolution.

Modern VGA displays

can accommodate

different resolutions, and

a VGA controller circuit

dictates the resolution by

producing timing signals

to control the raster

patterns. The controller

must produce TTL-level synchronizing pulses to set the frequency at which current flows through the

deflection coils, and it must ensure that pixel (or video) data is applied to the electron guns at the

correct time. Video data typically comes from a video refresh memory, with one or more bytes

assigned to each pixel location (the DIO2 board uses 8-bits per pixel). The controller must index into

video memory as the beams move across the display, and retrieve and apply video data to the display

at precisely the time the electron beam is moving across a given pixel.

Cathode ray tube display system

Anode (entire screen)

High voltage supply

(>20kV)

Control board

Deflection coils

Grid

Electron guns

(Red, Blue, Green)

gun

control

grid

control

deflection

control

R,G,B signals (to guns)

Sync signals

(to deflection control)

Cathode ray tube

Cathode ray

VGA cable