Carl Goldberg GBGA0067 User Manual

Page 32

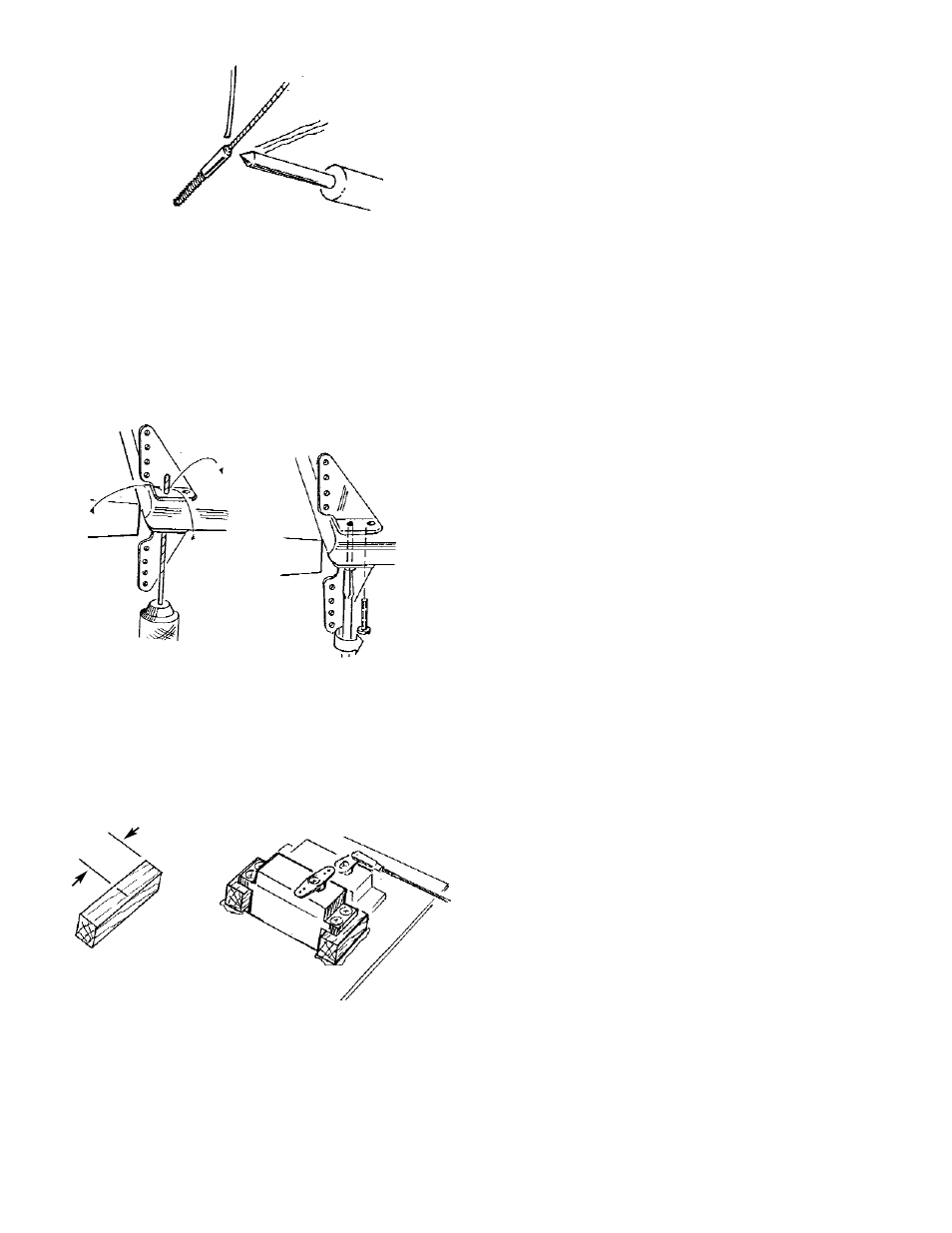

2. Solder a threaded coupler to one end of each

cable.

Lay the cable over the plan and cut to length.

Solder a threaded coupler to the cut end of

each cable.

3. Glue the hooded exits to the fuselage and

thread the cable assemblies from the rudder

servo opening to the control horns.

4. Install a CONTROL HORN on each side of the

rudder, directly opposite from one another.

Drill two 1/16” holes into one of the horn and

thread the two 2-56 screws into the horn.

5

Thread the SNAP LINKS onto the threaded

couplers and attach the links onto the rudder

control horns.

5. Cut the remaining 3/8 sq. piece of bass from

the elevtor pushrod into a 2” length. Then, cut

this piece into two equal pieces.

Glue the two small blocks to the servo tray to

raise the rudder servo, as shown on the plan.

Mount the servo (a ball-bearing servo is rec-

ommended) and, with the servo in the neutral

position, attach and adjust the cables until the

rudder is centered.

NOTE: Cables need only be tight enough to eliminate

slack.

32

RUDDER SERVO

SERVO TRAY

2-56 x 3/4"

SCREW

1/16" DRILL

SOLDER

1"