Carl Goldberg GBGA0067 User Manual

Page 25

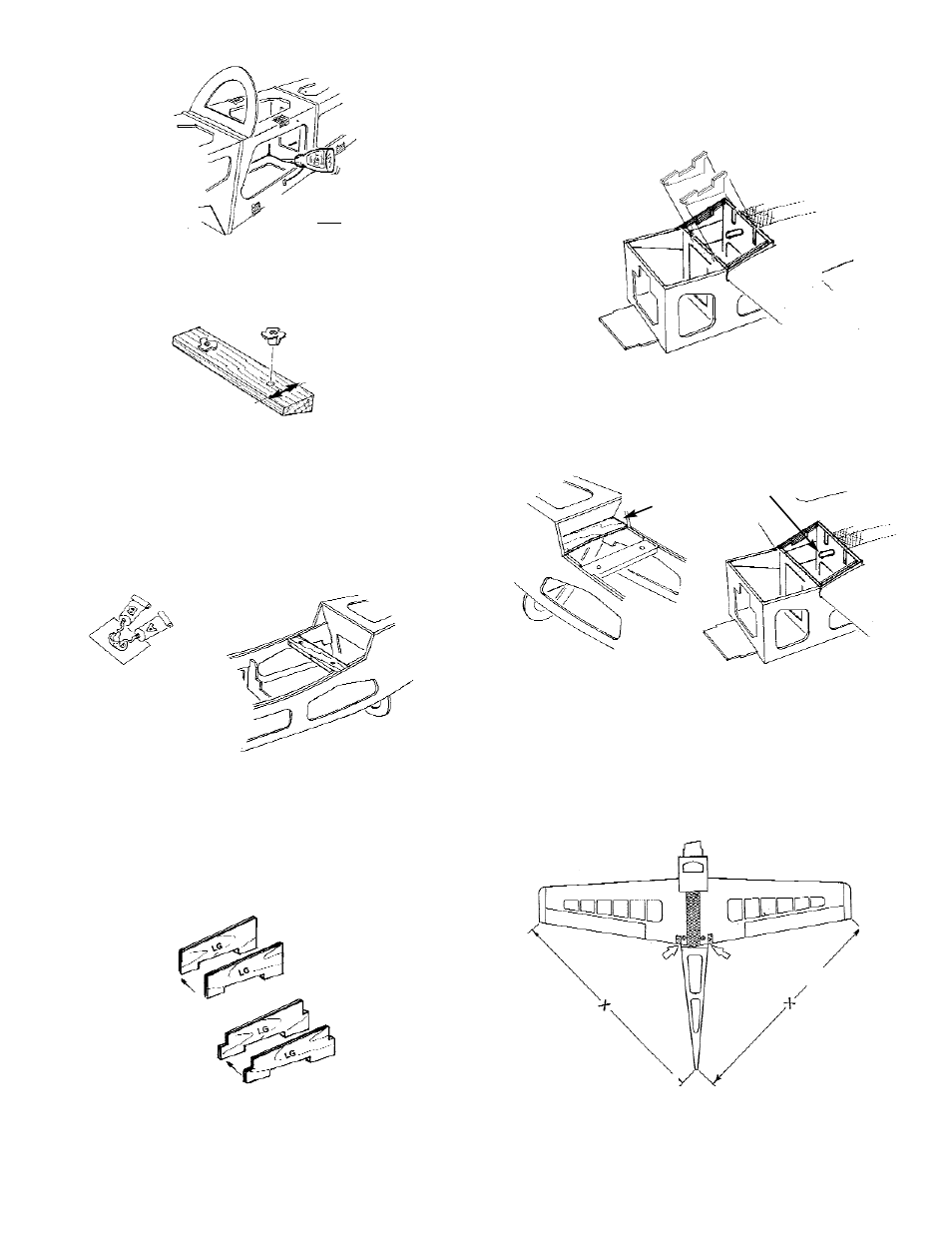

11. When the fuselage is perfectly aligned, glue all

of the areas where the sides, top, bottom, and

formers join.

12. Insert the remaining 6-32 blind nuts into the pre-

drilled holes in the WING MOUNTING BLOCK.

NOTE: Make sure the blind nuts are inserted into the

side of the mounting block where the holes are

centered.

Tap with a hammer to ensure the spurs are fully

set into the wood.

13. With the blind nuts on the inside the fuse, place

the mounting block into the cut-outs in the wing

saddle doubler and the fuselage sides. Trim, if

necessary, to achieve a good fit. Then, using

epoxy, glue in place.

NOTE: THIS IS A HIGH STRESS AREA. THE BET-

TER THE MOUNTING BLOCK FITS INTO THE

SOCKET, THE STRONGER THE JOINT WILL BE.

14. Form four 2-ply assemblies from the four LAND-

ING GEAR DOUBLERS.

When the laminated assembles are dry, test fit

in position. The assemblies with the tabs fit at

the slotted locations between Former B and

Former B2. The assemblies without the tabs

go along the fuse sides.

Epoxy securely in place.

15. Epoxy the 1/4 x 2-1/4 x 5-11/16” ply landing gear

plate between the fuse sides and into landing

gear doublers.

Now get the wing, which will be needed for the next

few steps.

16. Place the fuselage, bottom up, on a flat surface.

Glue the WIND STOP to the fuse sides and the

doublers.

Insert the wing dowel through the slightly over-

sized hole in Former B2. Slide the wing as far

forward as it will go. Make sure that the wing fits

tightly all along the wing saddle.

17. True the wing to the fuselage by adjusting the

distance from the wing-tip to the tail until both

dimensions are equal. Mark the wing for refer-

ence and tape in place.

25

HOLE IS CENTERED

TABBED DOUBLERS

UNTABBED DOUBLERS

MARK WITH TAPE

WIND STOP

L.G. PLATE

GLUE ALL SEAMS

WING DOWEL