Carl Goldberg GBGA0067 User Manual

Page 23

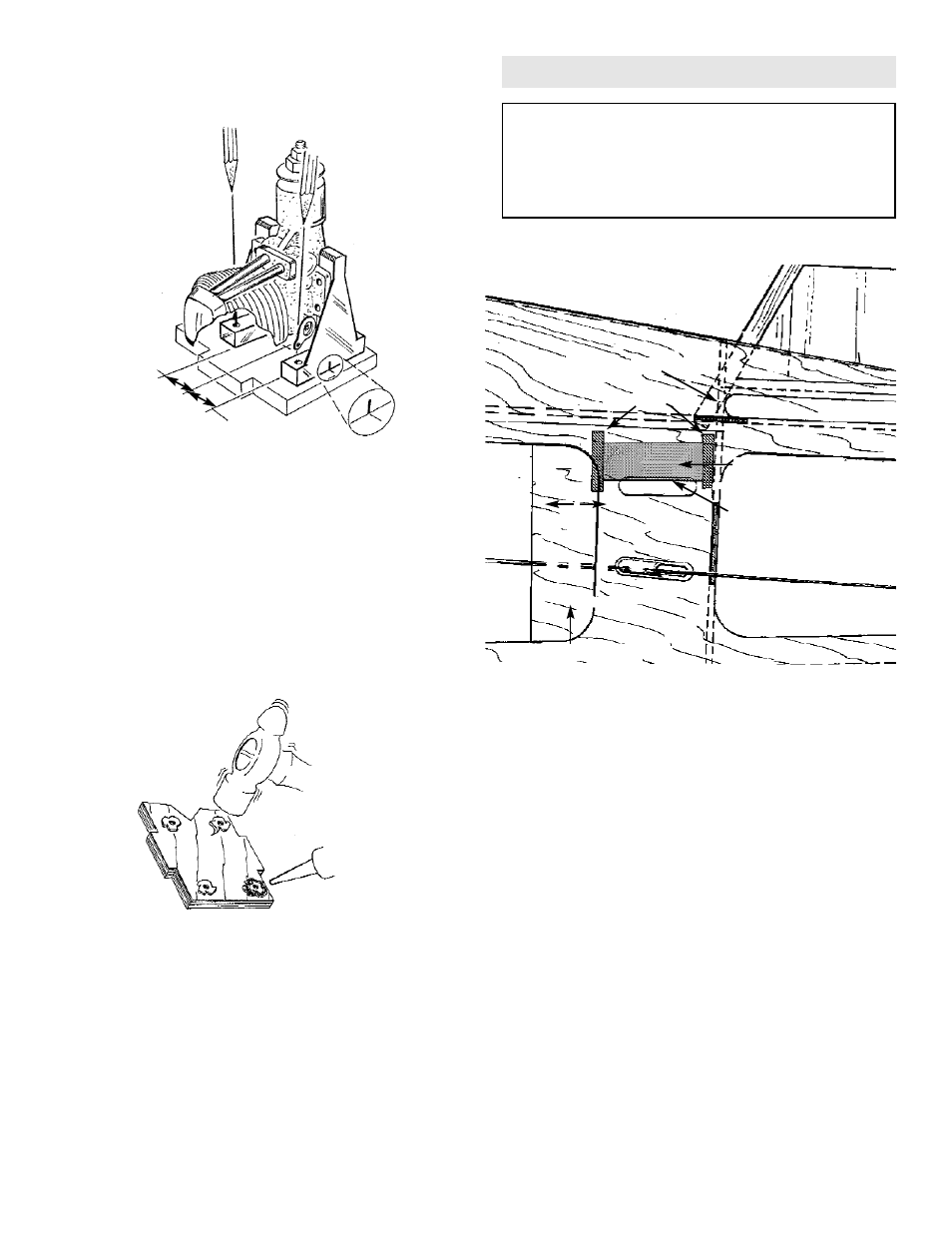

3. When the firewall has thoroughly dried, tack-

glue the motor you intend to use to the

ENGINE MOUNTS.

Align the marks on the engine mounts with the

vertical marking line on the firewall.

Center the engine mounts on the horizontal

marking line, as shown, and mark all four hole

locations.

Mark the location of the throttle pushrod exit in

line with the throttle control.

4. Drill a 5/32” diameter hole at each hole loca-

tion.

Flip the firewall over and insert four 6-32

BLIND NUTS. Seat them with a soft hammer

blow.

Making sure that the glue does not get into the

threads, coat the edges of each blind nut with

CA glue. Then, set the firewall aside.

NOTE: Flying the Sukhoi with one of the larger

recommended engines will produce spectacular

results. However, these larger 4-stroke engines

generate a lot of vibration. Therefore, you may

wish to install two elevator servos. If you choose

this option, refer to the following instructions.

(a) Do not punch out the elevator exit. Instead, glue it

permanently in place.

(b) Cut a hole for the servo on each side of the fuse-

lage, as shown.

(c) Make two doublers from scrap 1/8 x 1/4 x 1-1/4"

ply and glue the forward doubler to the INSIDE of

the fuselage. Glue the rear doubler to the OUT-

SIDE of the fuselage. This helps to position the

servo more parallel to the elevator pushrod.

(d) From the fuse side punch-out, cut off about a 1”

piece from the end and glue this strip back into the

fuse.

(e) When mounting the servos, it is essential that one

of the servos be reversed. The easiest way to

accomplish this is to use a special Y- harness

that will reverse one servo from the other.

Alternatively, "mix" your elevator channel into an

exta channel in your radio, and then reverse to

achieve proper direction. Consult your radio man-

ual for details.

(f) Using the elevator pushrod wire supplied in the kit,

trim to fit, making sure there are no bends. When

adjusting throws, try to get both elevators to move

equally.

TWO SERVO OPTION

Tape together and place under a weight until

dry.

23

1/2 ENGINE WIDTH

ALIGN MARKS

PLY DOUBLER

SERVO CUT-OUT

DO NOT REMOVE

FROM PUNCH-OUT

1”

FORMER J