Carl Goldberg GBGA0067 User Manual

Page 30

CONTROL SURFACE/RADIO INSTALLATION

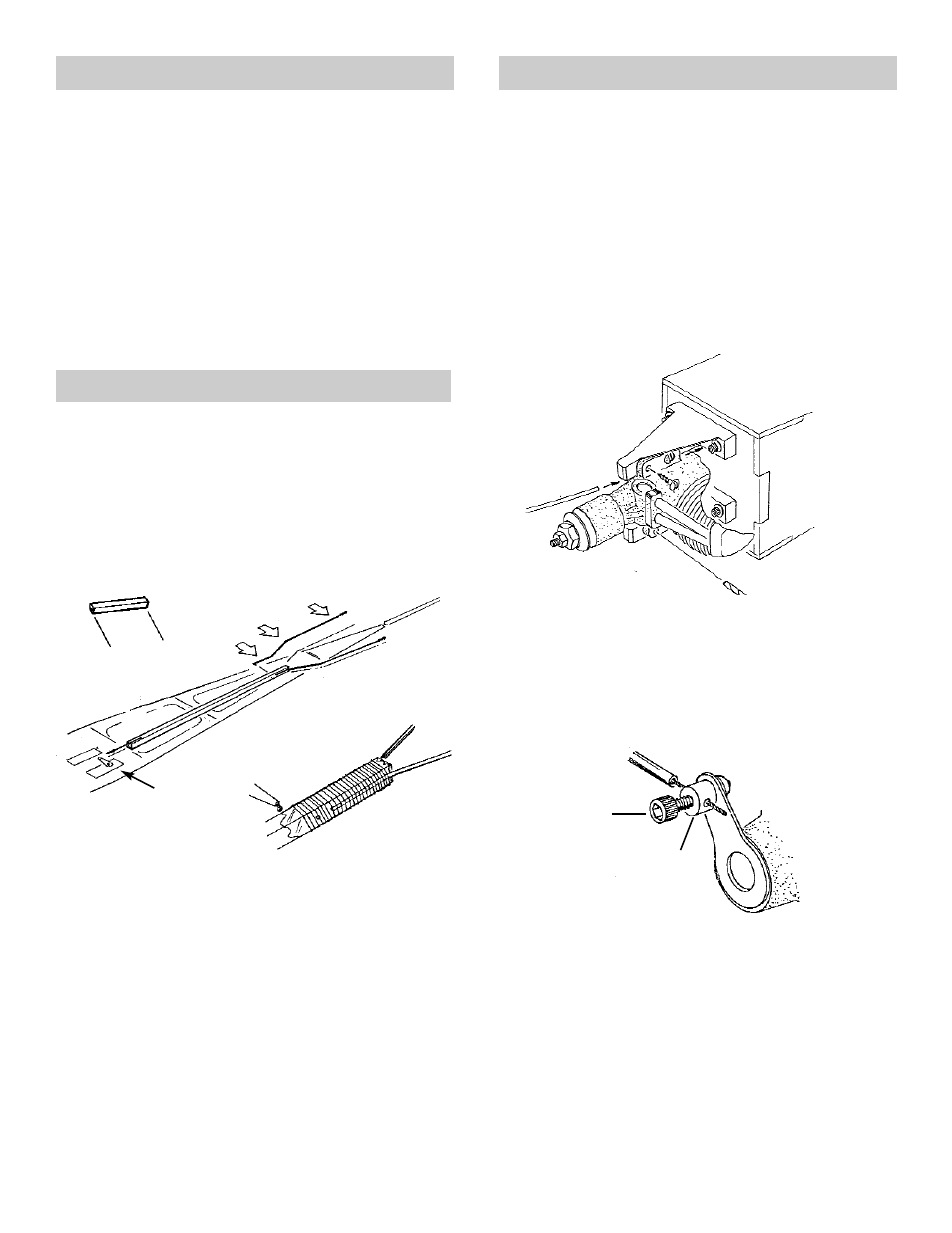

ENGINE PUSHROD INSTALLATION

1. Collect the following items:

(1) 3/8" x 3/8" x 16" BASS

PT.#3674

PUSHROD

(2) LONG CONTROL HORNS

PT.#1407

(4) 2-56 x 3/4" PAN HEAD SCREWS

PT.#1042

(3) SNAP LINKS

PT.#1405

(2) HOODED PUSHROD EXITS

PT.#1453

(1) .078 x 10" THREADED ROD

PT.#1272

(2) .078 x 13-5/8" THREADED ROD

PT.#1281

1. If you did not do so immediately after covering

the model, thin CA glue the hinges in place,

permanently attaching the elevator to the stab

and the rudder to the fin.

Permanently install the ailerons on the wings.

2. Referring to the GENERAL INFORMATION

BOOK and to the specific details and guide-

lines that came with your radio system, install

the radio, servos, and battery. A servo tray is

provided in this kit; however, it may be neces-

sary to modify it to suit your equipment.

ELEVATOR PUSHROD INSTALLATION

2. Cut 3-1/2” off the end of the basswood

pushrod. Set this piece aside, as it will be

need for attaching the cowling and for elevat-

ing the rudder servo.

3. Using the TOP VIEW of the fuse plan as a tem-

plate, bend the two 13-5/8” threaded rods in

the correct configuration.

Glue the rods to the bass pushrod and wrap

with a strong thread. Coat the thread with

more glue.

4. Referring to the plan, cut the 10” threaded rod

to size. Attach to the other end of the bass

pushrod, wrapping with string and coating with

glue.

1. Gather the necessary parts.

(4) 6-32 x 3/4" SOCKET HEAD SCREW

PT.#1022

(4) #6 M.S. WASHER

PT.#1140

(1) .034 I.D. x 18" NYLON TUBE

PT.#1657

(1) .030 x 34" CABLE

PT.#1289

(2) P.R. CONNECTOR BODY

PT.#1375

(2) 4-40 x 3/16" SOCKET HEAD SCREW PT.#1003

(1) NYLON SNAP-NUT (6/set)

PT.#1461

(4) #6 x 3/4" SHT. METAL SCREW

PT.#1082

2. Bolt the MOTOR MOUNTS to the firewall,

using four 6-32 x 3/4” SOCKET HEAD

SCREWS and #6 washers.

3. Referring to the plan for correct engine/cowl

position, screw the engine to the mounts with

four #6 x 3/4” SHEET METAL SCREWS.

4. Insert the NYLON GUIDE TUBE in the previ-

ously drilled hole in the firewall. Glue in place.

5. Install the CONNECTOR BODIES to the

engine throttle arm and the throttle servo arm.

Secure with the NYLON SNAP-NUT.

6. Thread the .030 x 34” CABLE through the

nylon tube and into the connector bodies.

With the servo at low motor position, and the

carburetor closed, lock both ends of the cable

with two 4-40 x 3/16” SOCKET HEAD

SCREWS.

7. Attach the fuel lines and install the muffler.

30

3-1/2"

PLAN

ELEVATOR SERVO

BEND WIRE PER PLAN

3/32" DRILL

CONNECTOR BODY

GUIDE TUBE

4-40 x 3/16" SOCKET

HEAD SCREW