Carl Goldberg GBGA0059 User Manual

Page 11

Referring to the TIP OPTION on the plan, care-

fully groove the spars for the wire and for the

brass tube.

G. Tack-glue the WIRE to the OUTBOARD SPAR

and the BRASS TUBE to the INBROARD

SPAR.

Plug the wing panels together and make cer-

tain the wing structures butt evenly at the poly-

hedral joint. If adjustments are needed, take

the panels apart and rework the grooves slight-

ly.

When satisfied with the fit of the joint, glue the

metal parts in place.

H. With the wing panels plugged together, posi-

tion the new #6 ribs at the polyhedral joint. The

ribs should be tilted slightly toward the out-

board panel, so that they match the spar angle.

TAKING CARE TO NOT GLUE THE WING

PANELS TOGETHER, carefully glue the ribs to

their respective wing panels.

I.

Unplug the wing panels. Then, working on first

the inboard panel and then the outboard panel,

wrap a about 2” of 3/4” wide nylon fabric

(included in your kit) around each of the spars

to secure the wire and brass tubing.

Saturate the nylon fabric with Super Jet or Jet

Epoxy, to create a sturdy bond.

WRAP NYLON AROUND SPARS,

TUBES, AND WIRES

11

J. Add gussets (D/C Sht. 4006) at the L.E. and

T.E., as shown above.

NOTE: This completes the removable tip option con-

struction for the first wing half. When working on the

second wing half, you again will follow the above

instructions. After the wing parts are covered, the

removable panels are fastened to the inboard wing

sections using vinyl electrical tape. This tape holds

firmly, yet can be removed without damaging the cov-

ering material.

NOW PROCEED DIRECTLY TO STEP 19.

14. With the outboard panel still pinned down, raise

the inboard panel and support it with the wing

dihedral gauges under the first rib #5 location, as

shown on the plan.

IMPORTANT: The end of the gauge stamped “A” must

be up. Hold the gauges firmly in place by tack-cement-

ing, clothespins, etc.

Carefully inspect the panel joint to make sure all

of the end pieces of the inboard panel fit tightly

to those of the outboard panel. If one part pro-

trudes too much, sand slightly for a better fit.

WARNING: always sand just a little at a time, so

that you do not remove too much wood. You

may find it helpful to use the sanding tool

described in the removable tip option.

15. TEMPORARILY install the diihedral joiners on

each side of the spars. Use die-cut clampls to

hold in place.

When satisfied with the fit of the inboard and out-

board panels, pin in place, as shown above.

16. Remove the dihedral joiners and apply a liberal

bead of Super Jet to all joints of the L.E., spars,

and T.E.

Quickly apply glue to the joiners and immediate-

ly reinstall. Use the clamps again to hold both

joiners tight to the spars. Allow to dry.

IMPORTANT: "A" AT TOP

MATCH GAUGES WITH PLAN

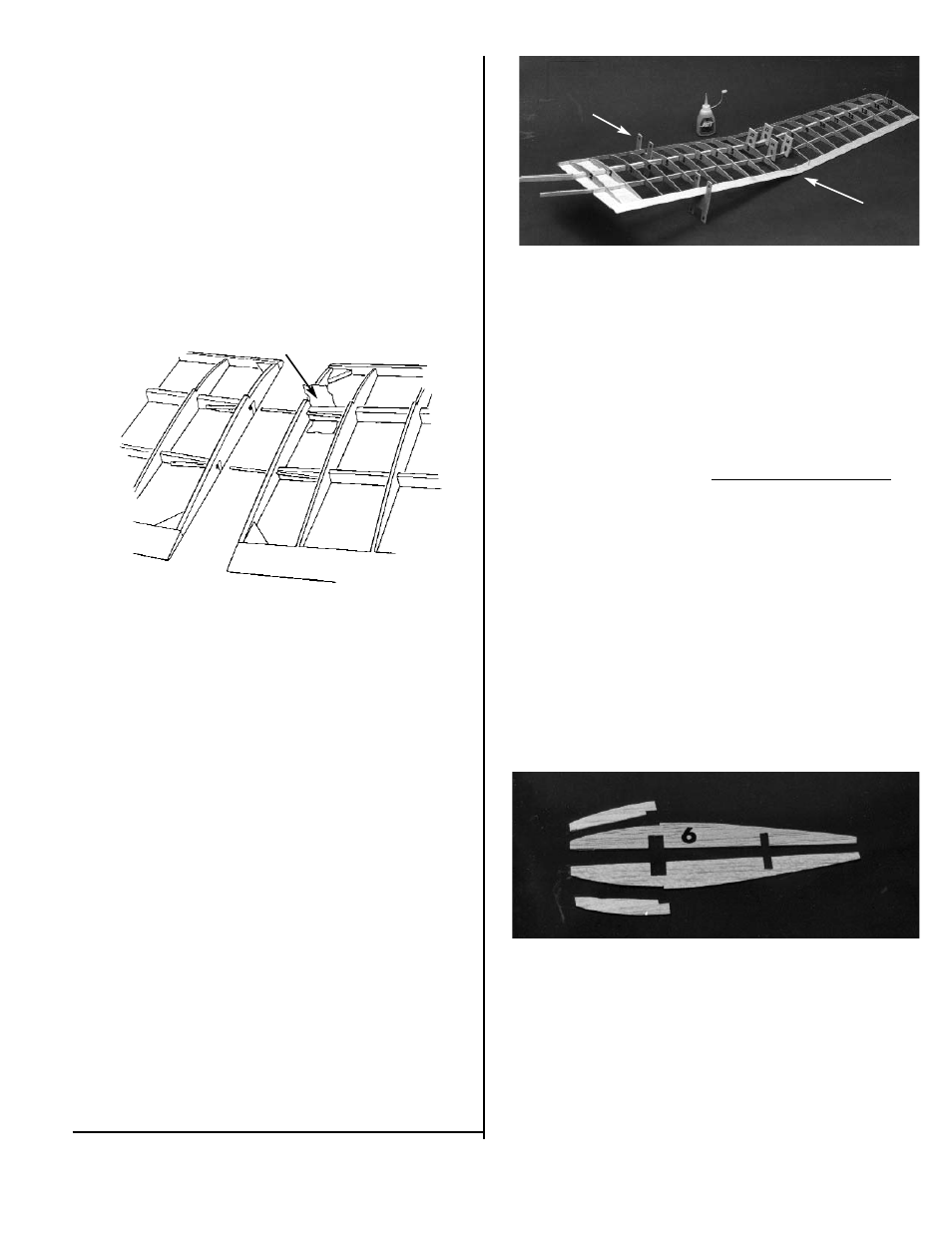

17. Lay out two #6 ribs, and two doublers, as

shown.

Glue rib doubler #6a to each rib, taking care to

make on left and one right rib.

18. Position rib #6 so that it aligns with the joints in

the L.E., the spars, and the T.E. Make sure that

the doubler is facing out, toward the outboard

pannel. When satisfied with the fit, glue in

place.

Referring to the plan for location, glue gussets to

rib #6, the L.E., and the T.E.