Installation – AERCO BMK 3.0 LN Nat. Gas APRIL 2009 User Manual

Page 13

INSTALLATION

2-3

2.4.3 Removal of Support Rod

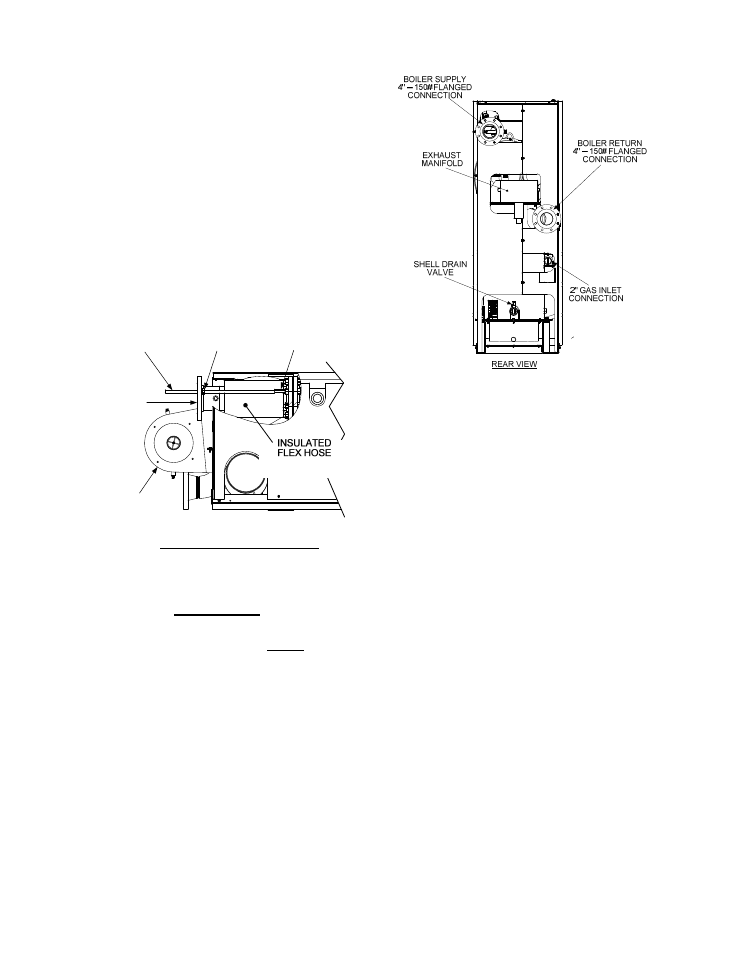

Prior to installation of water supply and return

piping, the 24” threaded rod shown in Figure 2-3

must be removed. This rod is installed prior to

shipment from the factory to prevent damage to

the insulated metal flex hose on the hot water

supply outlet of the boiler. In order to install the

water supply piping, this rod must be removed

as follows:

1. Refer to Figure 2-3 and back off the hex nut

on the outlet side of the flex hose.

2. Next, disconnect the coupling nut from the

flange stud.

3. Completely remove the threaded rod, hex

nut and coupling nut from the boiler.

5/8-11 x 24" LONG

THREADED ROD

5/8-11

HEX NUT

5/8-11

COUPLING NUT

EXHAUST

MANIFOLD

OUTLET

FLANGE

(SEE IMPORTANT

NOTE BELOW)

PARTIAL TOP VIEW - REAR

Figure 2-3

Location of Threaded Support Rod

IMPORTANT

THE INSULATED FLEX HOSE

SHOWN IN FIGURE 2-3 MUST BE

LEVEL OR SLOPING UPWARD AS

IT EXITS THE BOILER. FAILURE TO

PROPERLY POSITION THIS HOSE

MAY CAUSE INEFFECTIVE AIR

ELIMINATION RESULTING IN ELE-

VATED TEMPERATURES THAT

COULD COMPROMISE THE TOP

HEAD GASKET.

2.5 SUPPLY AND RETURN PIPING

The Benchmark 3.0 Boiler utilizes 4” 150#

flanges for the water system supply and return

piping connections. The physical location of the

supply and return piping connections are on the

rear of the unit as shown in Figure 2-4. Refer to

Appendix F, Drawing AP-A-811 for additional

dimensional data.

Figure 2-4

Supply and Return Locations

2.6 CONDENSATE DRAINS

The Benchmark 3.0 Boiler is designed to

condense water vapor from the flue products.

Therefore, the installation must have provisions

for suitable condensate drainage or collection.

Two condensate drain connections are provided

on the rear of the unit as shown in Figure 2-5.

One drain connection is located on the exhaust

manifold and the other is located on the

connecting manifold.

The drain at the bottom of the exhaust manifold

also includes a condensate trap containing a

float assembly. When condensate collects in the

exhaust manifold, the float rises, thereby

allowing it to discharge through the drain

opening. The drain pipe located on the

connecting manifold must be connected to a

second condensate trap which is packed

separately within the unit’s shipping container.

The procedures to install and connect both of

the condensate drains are provided in

paragraphs 2.6.1 and 2.6.2.