Chapter 6 - safety device testing, Safety device testing, Chapter 6 safety device testing – AERCO BMK 3.0 LN Nat. Gas APRIL 2009 User Manual

Page 45

SAFETY DEVICE TESTING

CHAPTER 6 SAFETY DEVICE TESTING

6.1 TESTING OF SAFETY DEVICES

Periodic safety device testing is required to

ensure that the control system and safety

devices are operating properly. The Benchmark

3.0LN control system comprehensively monitors

all combustion-related safety devices before,

during and after the start sequence. The

following tests check to ensure that the system

is operating as designed.

Operating controls and safety devices should be

tested on a regular basis or following service or

replacement. All testing must conform to local

codes such as ASME CSD-1.

NOTE

MANUAL and AUTO modes of operation

are required to perform the following

tests. For a complete explanation of these

modes, see Chapter 3.

NOTE

It will be necessary to remove the front

door and side panels from the unit to

perform the following tests.

WARNING

ELECTRICAL VOLTAGES IN THIS

SYSTEM MAY INCLUDE 460, 220,

120 AND 24 VOLTS AC. POWER

MUST BE REMOVED PRIOR TO

PERFORMING WIRE REMOVAL OR

OTHER TEST PROCEDURES THAT

CAN RESULT IN ELECTRICAL

SHOCK.

6.2 LOW GAS PRESSURE FAULT TEST

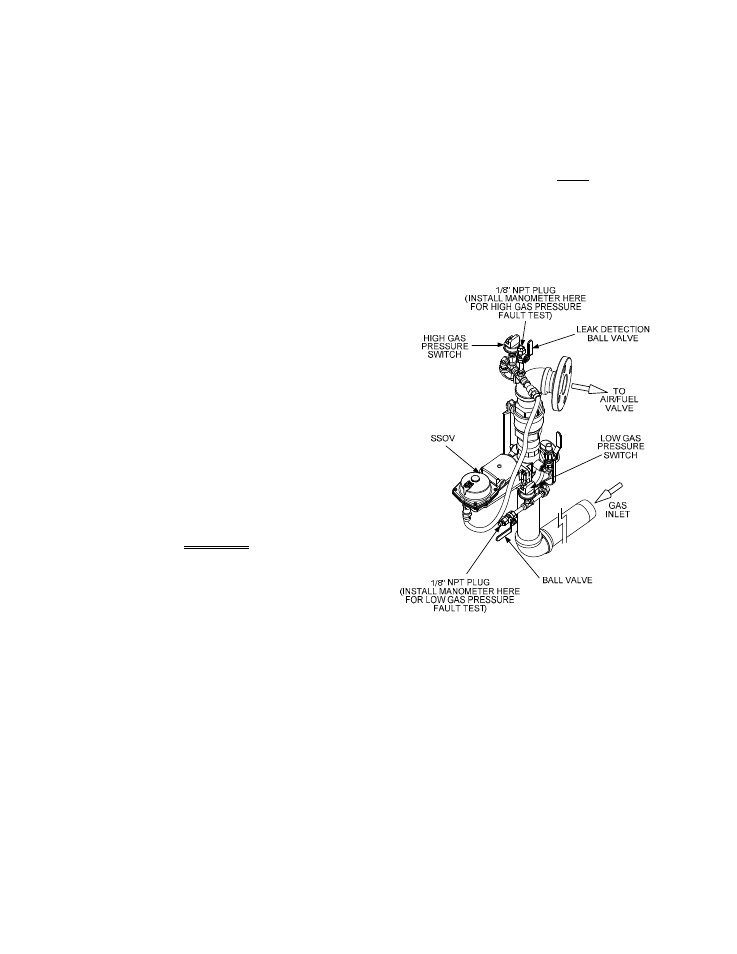

Refer to Figure 6-1 and ensure that the leak

detection ball valve located at the high gas

pressure switch is closed.

1. Remove the 1/8 “ plug from the ball valve at

the low gas pressure switch shown in the

lower portion of Figure 6-1.

2. Install a 0 – 16 “ W.C. manometer or a W.C.

gauge where the 1/8" plug was removed.

3. Slowly open the ball valve near the low gas

pressure switch.

4. Place the unit in Manual Mode and adjust

the firing rate between 25 and 30%.

5. While the unit is firing, slowly close the

external manual gas shut-off valve.

6. The unit should shut down and display a

LOW GAS PRESSURE fault message at

approximately 2.6” W.C. The FAULT indi-

cator should also start flashing.

Figure 6-1

Low & High Gas Pressure Testing

7. Fully open the external manual gas shut-off

valve and press the CLEAR button on the

Control Box.

8. The fault message should clear and the

FAULT indicator should go off. The unit

should restart.

9. Upon test completion, close the ball valve

and remove the manometer. Replace the

1/8 “ plug removed in step 1.

6-1