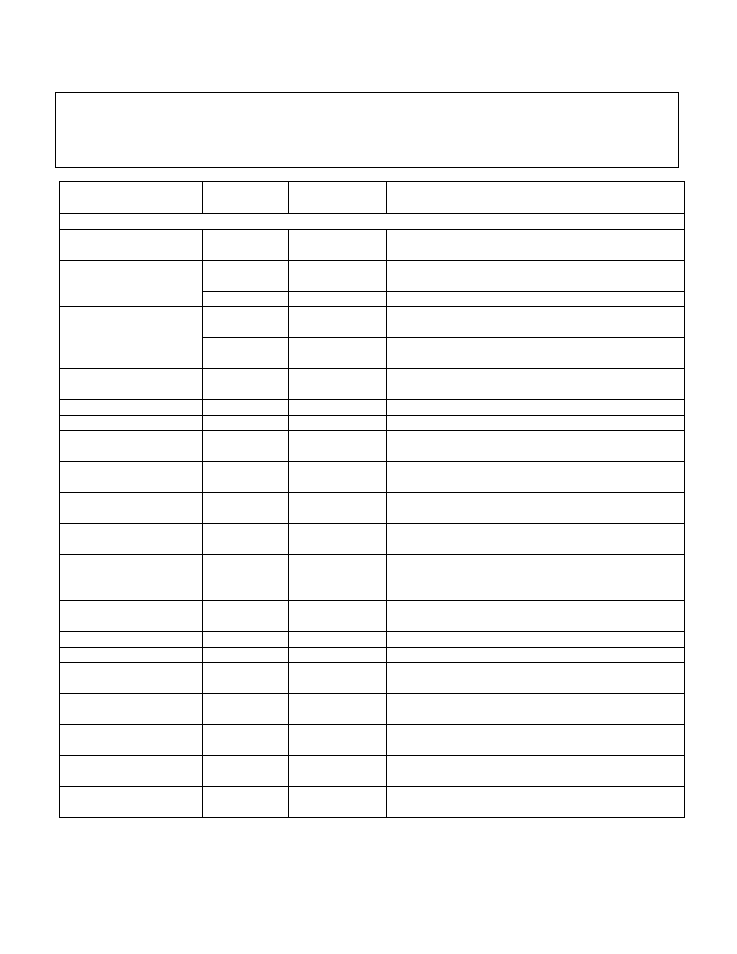

Appendix i - recommended periodic check list – AERCO BMK 3.0 LN Nat. Gas APRIL 2009 User Manual

Page 115

APPENDIX I

I-1

RECOMMENDED PERIODIC TESTING CHECK LIST

WARNING

NOTE: Periodic testing of all boiler controls and safety devices is required to determine that they are operating as

designed. Precautions shall be taken while tests are being performed to protect against bodily injury and property

damage. The owner or user of an automatic boiler system should set up a formal system of periodic preventive

maintenance and testing. Tests should be conducted on a regular basis and the results recorded in a log-book.

Item

Frequency

Accomplished

By

Remarks

Refer to indicated paragraphs of this manual for detailed procedures

Gauges, monitors and

indicators

Daily Operator

Visual inspection and record readings in operator

log

Instrument and

equipment settings

Daily Operator

Visual check against factory recommended

specifications

Weekly

Operator

Verify factory settings

Firing Rate Control

Semi-

Annually

Service

Technician

Verify factory settings

Annually

Service

Technician

Check with combustion calibration test

equipment. See paragraph 7.4 and Chapter 4.

Flue, vent, stack or

intake air duct

Monthly Operator

Visually inspection condition and check for

obstructions

Igniter

Weekly

Operator

See paragraph 7.2

Air/Fuel Valve position

Weekly

Operator

Check position indicator dial (paragraph 3.8)

SSOV Leakage test

Annually

Service

Technician

Check for leakage in accordance with the SSOV

manufacturer’s (Siemens) recommendations.

Flame failure

Weekly

Operator

Close manual gas shutoff valve and check safety

shutdown. See paragraph 6.7

Flame signal strength

Weekly

Operator

Check flame strength using the Control Panel

Operating Menu. See paragraph 3.4.

Low water level cut off

and alarm

Weekly

Operator

See paragraph 6.4

Slow drain test

Semi-

Annually

Operator

Perform a slow drain test in accordance with

ASME Boiler and Pressure Vessel Code,

Section IV.

High water temperature

safety control test

Annually

Service

Technician

See paragraph 6.4

Operating controls

Annually

Operator

See paragraph 3.2

Low air flow

Monthly

Operator

See paragraph 6.6

High and low gas

pressure interlocks

Monthly

Operator

See paragraphs 6.2 and 6.3

Air/Fuel Valve purge

position switch

Annually

Service

Technician

See paragraph 6.10

Air/Fuel Valve ignition

position switch

Annually

Service

Technician

See paragraph 6.11

Safety valves

As required

Operator

Check per A.S.M.E. Boiler and Pressure Vessel

Code, Section IV

Inspect burner

components

Semi-

Annually

Service

Technician

See paragraph 7.6