Troublesho oting – AERCO BMK 3.0 LN Natural Gas July 2011 User Manual

Page 69

TROUBLESHO

OTING

8-11

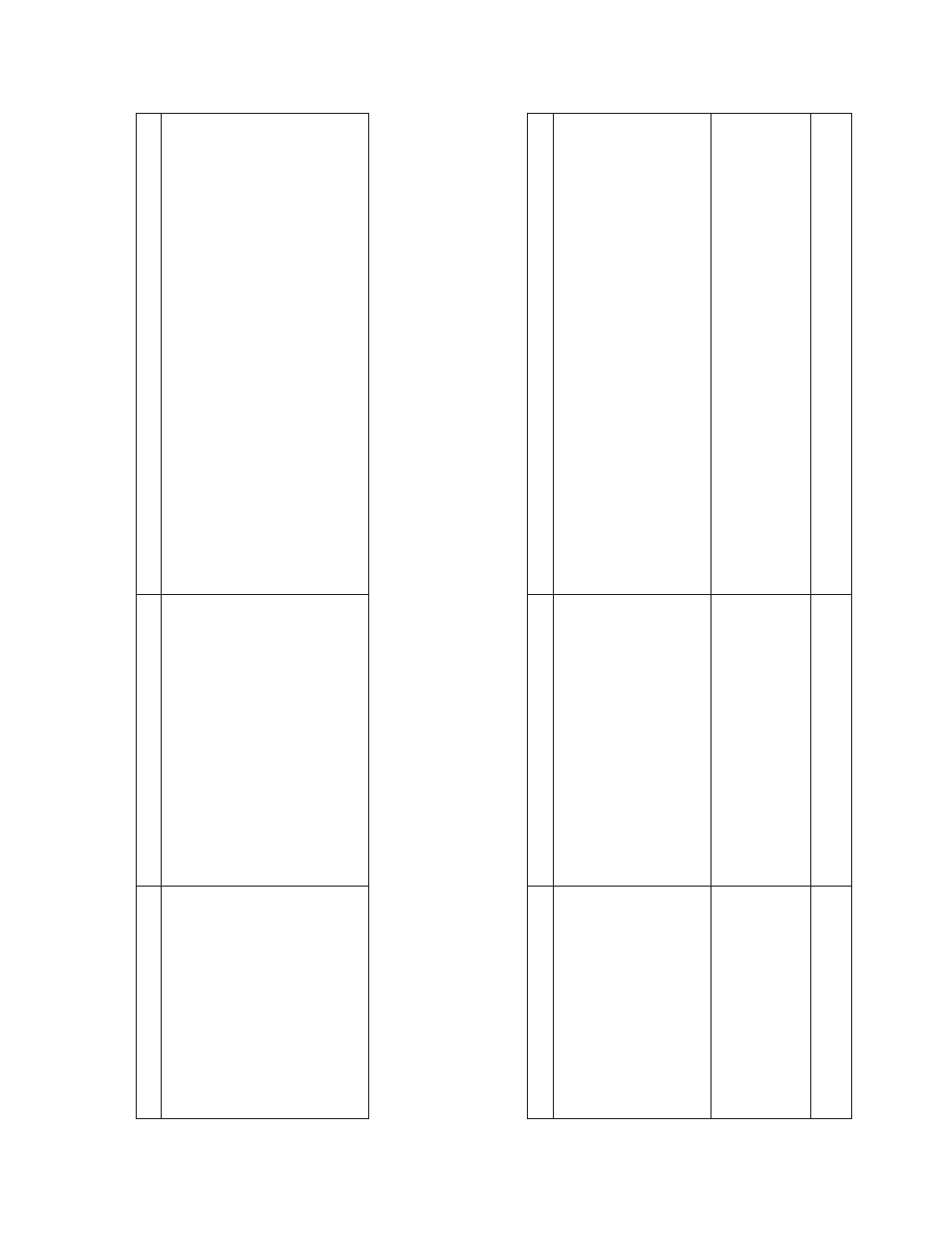

TABLE 8-1. BOILER TRO

UBLESHOOTING – Contin

ued

FAULT INDICATION

PROBABL

E CAU

SES

CORRECTI

VE ACTI

O

N

(co

ntinue

d)

2.

Air/Fuel Valve unplu

gged.

3.

Loo

se

wirin

g co

nne

ctio

n to the

stepp

er moto

r.

4.

Defe

ctive Ai

r/Fuel V

alve

step

pe

r

motor.

5.

Defe

ctive Power Su

pply Board o

r

fus

e

6.

D

efec

tive IGST Board

2.

Che

ck that the Air/Fuel Val

ve is con

ne

cted to the Con

trol Box.

3.

Ins

pec

t for loos

e

co

nnec

tions

b

etwe

en

the Air/Fuel Valve motor

and the wi

rin

g harn

ess.

4.

Repl

ace step

per moto

r.

5.

Che

ck DS1 &

DS2 LEDs o

n Powe

r Sup

ply Board. If they are not

steady O

N

, repla

ce Power Supply Board.

6.

Che

ck “Hea

rtbeat” LE

D DS1 and verify it is blinkin

g ON & OFF

every se

con

d.

If not, replace IGST Board

.

8.2 ADDITI

ONAL

FAULTS

WITHOU

T SPECIFIC F

AULT MESSAGES

Refer to Ta

bl

e 8-2 to trou

bl

esh

oot faults which may

occur with

out a spe

cific faul

t

message be

ing displayed.

TABL

E 8-2. BOILER TROUBLESHOOTIN

G WITH NO FAULT MESSAGE DISPLAYED

OBS

E

RVE

D

INCID

E

N

T

PROBABL

E CAU

SES

CORRECTI

VE ACTI

O

N

Hard Light

-Of

f

1.

Staged Ignitio

n Ball Valve close

d.

2. Clog

ged/da

m

aged

Ignito

r-

Injector

(Figu

re 8

-2).

3.

Defe

ctive Staged Ignition S

olenoi

d

(Figu

re 8

-2)

1.

Open the 1/4

” Ball Valve down

strea

m of the SSOV (Fi

g. 8-1).

2.

Remove a

nd

insp

ect ga

s in

jector

to ens

ure it is

not c

logged or

damag

ed.

3.

Clo

se the 2”

and the 1/4”

Ball Valve down

strea

m

of the SSOV

(Fig. 8-1). Start the unit and lis

ten for a “clic

ki

ng”

so

und that the

Staged Ignitio

n Solenoid m

ake

s du

ring I

gnition Tri

al. If “clicking

”

sou

nd is n

ot heard after 2

or 3 attempts,

r

epla

ce the

Staged

Ignition Solenoid.

Fluctuatin

g G

as Pre

ssure

1.

Gas

pr

es

sure going into un

it is

fluctuating.

2. Dampi

ng

O

rific

e not in

stalle

d.

1.

Stabilize ga

s

pre

ssure goin

g in

to unit. If

necess

ary, troubles

hoot

Building Sup

ply Regul

ator.

2.

C

heck

to ensure that the Damp

ing Orifice is installed in the

SSOV Actuator (Fig

ure 8-3

). For IRI Ga

s Train

s, the Damping

Orifice i

s inst

alled in the d

own

stre

am SSOV Actuator.

Air/Fuel Valve “huntin

g” at

80%

valve position

1.

IGST and Po

wer Su

pply Board

s in

Control Box are outdate

d.

1.

Che

ck to ensure that the IGST and Po

wer Su

pply Board

s a

re

Rev. E or hig

her.