Installation – AERCO BMK 3.0 LN Natural Gas July 2011 User Manual

Page 17

INSTALLATION

2-5

2.7 GAS SUPPLY PIPING

The AERCO

Benchmark 3.0

Gas Components

and Supply Design Guide, GF-3030 must be

consulted prior to designing or installing any gas

supply piping.

WARNING

NEVER USE MATCHES, CANDLES,

FLAMES OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS

LEAKS

.

CAUTION

Many soaps used for gas pipe leak

testing are corrosive to metals. There-

fore, piping must be rinsed thoroughly

with clean water after leak checks

have been completed.

NOTE

All gas piping must be arranged so that it

does not interfere with removal of any

covers, inhibit service/maintenance, or

restrict access between the unit and

walls, or another unit.

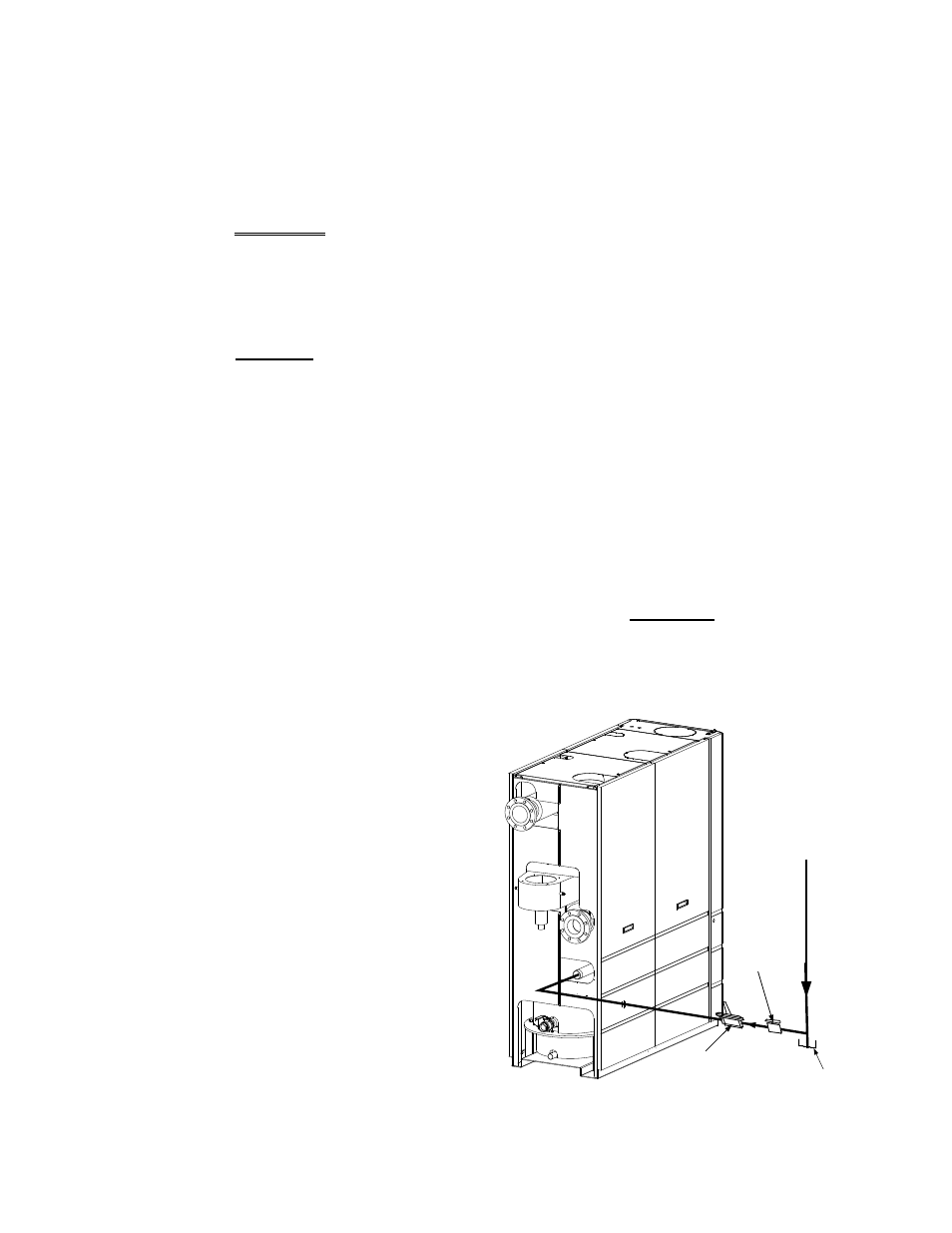

A 2 inch gas inlet connection is located on the

rear of the unit as shown in Figure 2-4.

Prior to installation, all pipes should be de-

burred and internally cleared of any scale, metal

chips or other foreign particles. Do Not install

any flexible connectors or unapproved gas

fittings. Piping must be supported from the floor,

ceiling or walls only and must not be supported

by the unit.

A suitable piping compound, approved for use

with natural gas, should be used. Any excess

must be wiped off to prevent clogging of

components.

To avoid unit damage when pressure testing gas

piping, isolate the unit from the gas supply

piping. At no time should the gas pressure

applied to the unit exceed 2 psi. Leak test all

external piping thoroughly using a soap and

water solution or suitable equivalent. The gas

piping used must meet all applicable codes.

2.7.1 Gas Supply Specification

The gas supply input specifications to the unit

for Natural Gas are as follows:

The maximum static pressure to the unit must

not exceed 2 psi. The gas supply pressure to the

unit must be of sufficient capacity to provide

3000 cfh while maintaining the gas pressure at

3.5” W.C. for FM or 4.0” for IRI gas trains.

2.7.2 Manual Gas Shutoff Valve

A manual shut-off valve must be installed in the

gas supply line upstream of the Boiler as shown

in Figure 2-7. Maximum allowable gas pressure

to the Boiler is 2 psi

NOTE

Paragraph 2.7.3 applies only to bolier

installations within the Commonwealth of

Massachusetts.

2.7.3 External Gas Supply Regulator

For Massachusetts installations, a mandatory

external gas supply regulator must be positioned

as shown in Figure 2-7. The gas supply

regulator must be properly vented to outdoors.

Consult the local gas utility for detailed

requirements concerning venting of the the

supply gas regulator.

NOTE

The external regulator must be capable of

regulating 3,00,000 BTU/HR of natural

gas while maintaining a gas pressure to

the boiler of 3.5” W.C. for FM or 4.0” W.C.

for IRI gas trains.

CAUTION

A lock-up style regulator MUST be

used when gas supply pressure will

exceed 14” W.C.

NATURAL

GAS

SUPPLY

DIRT

TRAP

2" MANUAL

SHUTOFF

VALVE

MANDATORY

REGULATOR FOR

MASSACHUSSETTS

INSTALLATIONS ONLY

Figure 2-7

Manual Gas Shut-Off Valve Location