Installation – AERCO BMK 3.0 LN Natural Gas July 2011 User Manual

Page 22

INSTALLATION

2-10

2.10.9 EXHAUST SWITCH IN

These terminals permit an external exhaust

switch to be connected to the exhaust manifold

of the boiler. The exhaust switch should be a

normally open type switch (such as AERCO Part

No. 123463) that closes (trips) at 500°F.

2.10.10 INTERLOCKS

The unit offers two interlock circuits for

interfacing with Energy Management Systems

and auxiliary equipment such as pumps or

louvers. These interlocks are called the Remote

Interlock and Delayed Interlock (Figure 2-11).

The wiring terminals for these interlocks are

located inside the I/O Box on the unit front

panel. The I/O Box cover contains a wiring

diagram which shows the terminal strip locations

for these interlocks (REMOTE INTL’K IN and

DELAYED INTL’K IN). Both interlocks,

described below, are factory wired in the closed

position.

IMPORTANT

Both the Remote Interlock and Delayed

Interlock MUST be in the closed position

to allow the unit to fire.

2.10.10.1 REMOTE INTERLOCK IN

The remote interlock circuit is provided to

remotely start (enable) and stop (disable) the

Boiler, if desired. The circuit is labeled

REMOTE INTL’K IN and is located inside the I/O

Box on the front panel. The circuit is 24 VAC

and is factory pre-wired in the closed (jumpered)

position.

2.10.10.2 DELAYED INTERLOCK IN

The delayed interlock is typically used in

conjunction with the auxiliary relay described in

paragraph 2.10. This interlock circuit is located

in the purge section of the start string. It can be

connected to the proving device (end switch,

flow switch etc.) of an auxiliary piece of

equipment started by the Boiler’s auxiliary relay.

The delayed interlock must be closed for the

boiler to fire.

If the delayed interlock is connected to a proving

device that requires time to close (make), a time

delay (Aux Start On Dly) that holds the start

sequence of the boiler long enough for a proving

switch to make can be programmed. Should the

proving switch not prove within the programmed

time frame, the boiler will shut down. The Aux

Start On Dly can be programmed from 0 to 120

seconds. This option is locate in the

Configuration Menu (Chapter 3, Table 3-4).

2.10.11 FAULT RELAY

The fault relay is a single pole double throw

(SPDT) relay having a normally open and

normally closed set of relay contacts that are

rated for 5 amps at 120 VAC and 5 amps at 30

VDC. The relay energizes when any fault

condition occurs and remains energized until the

fault is cleared and the CLEAR button is

depressed. The fault relay connections are

shown in Figure 2-11.

2.10.12

BENCHMARK PUMP RELAY

OPTION

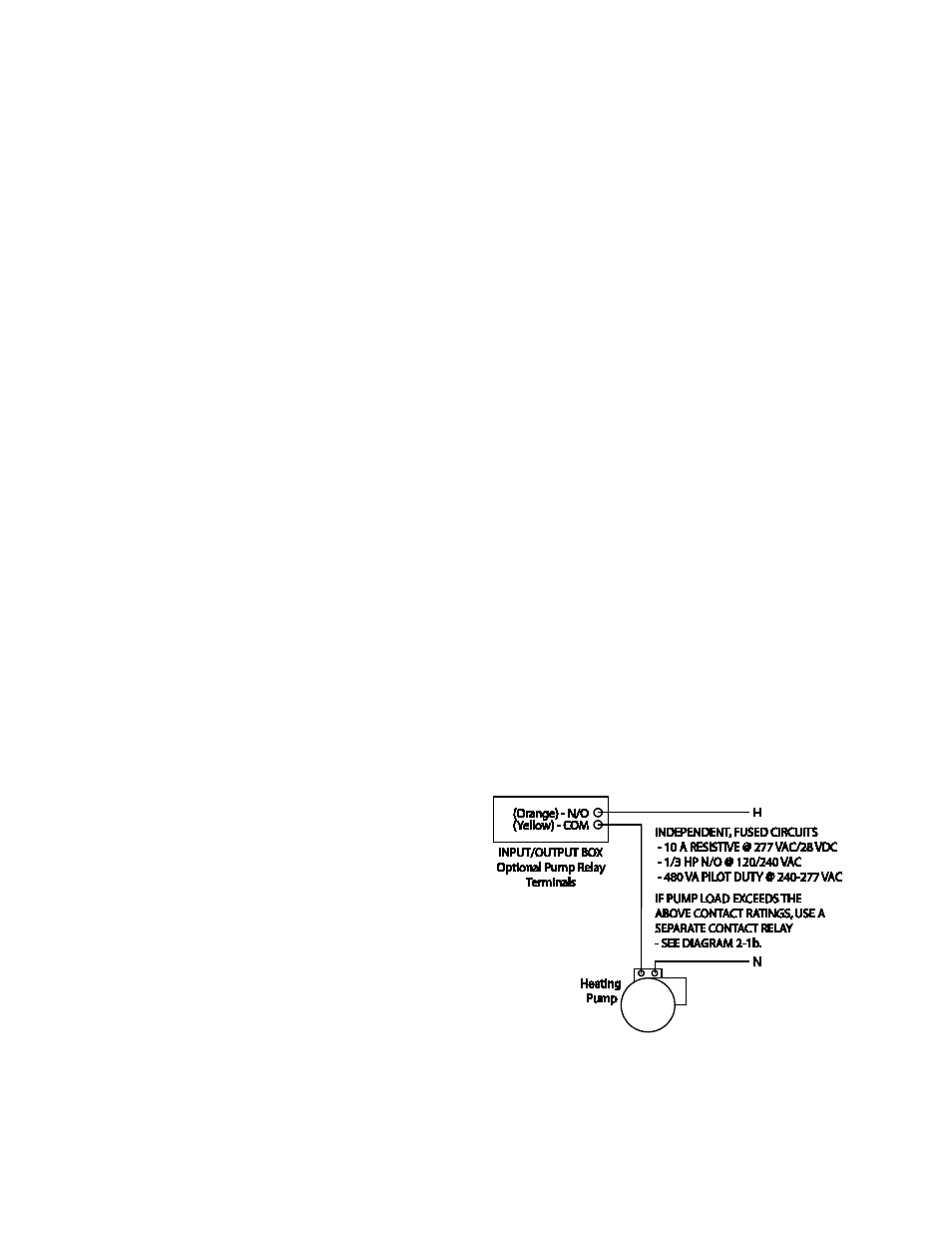

An optional Benchmark pump relay allows the

user to turn a pump on/off and open/close a

motorized valve as the boiler cycles on and off

on demand. The Pump Delay Timer feature

allows the user to keep the pump running and

keep the motorized valve open for up to 30

minutes after the boiler has shut down and the

demand is satisfied.

The Benchmark pump relay (SPDT) contact is

rated for:

•

10 A Resistive @ 277 VAC/28 VDC

•

1/3 HP N/O @ 120/240 VAC

•

1/6 HP N/C @ 120/240 VAC

•

480 VA Pilot Duty @ 240-277 VAC

If pump/valve load exceeds the above contact

ratings, use a separate contact relay.

See Diagrams 2-1a and 2-1b.

To identify if the boiler is equipped with the BMK

Pump Relay Option (part no. 69102), look for the

label and relay as shown in Figure 2-12.

Diagram 2-1a: Schematic – System Pump

Start using Boiler Pump Relay