Troublesho oting – AERCO BMK 3.0 LN Natural Gas July 2011 User Manual

Page 64

TROUBLESHO

OTING

8

-

6

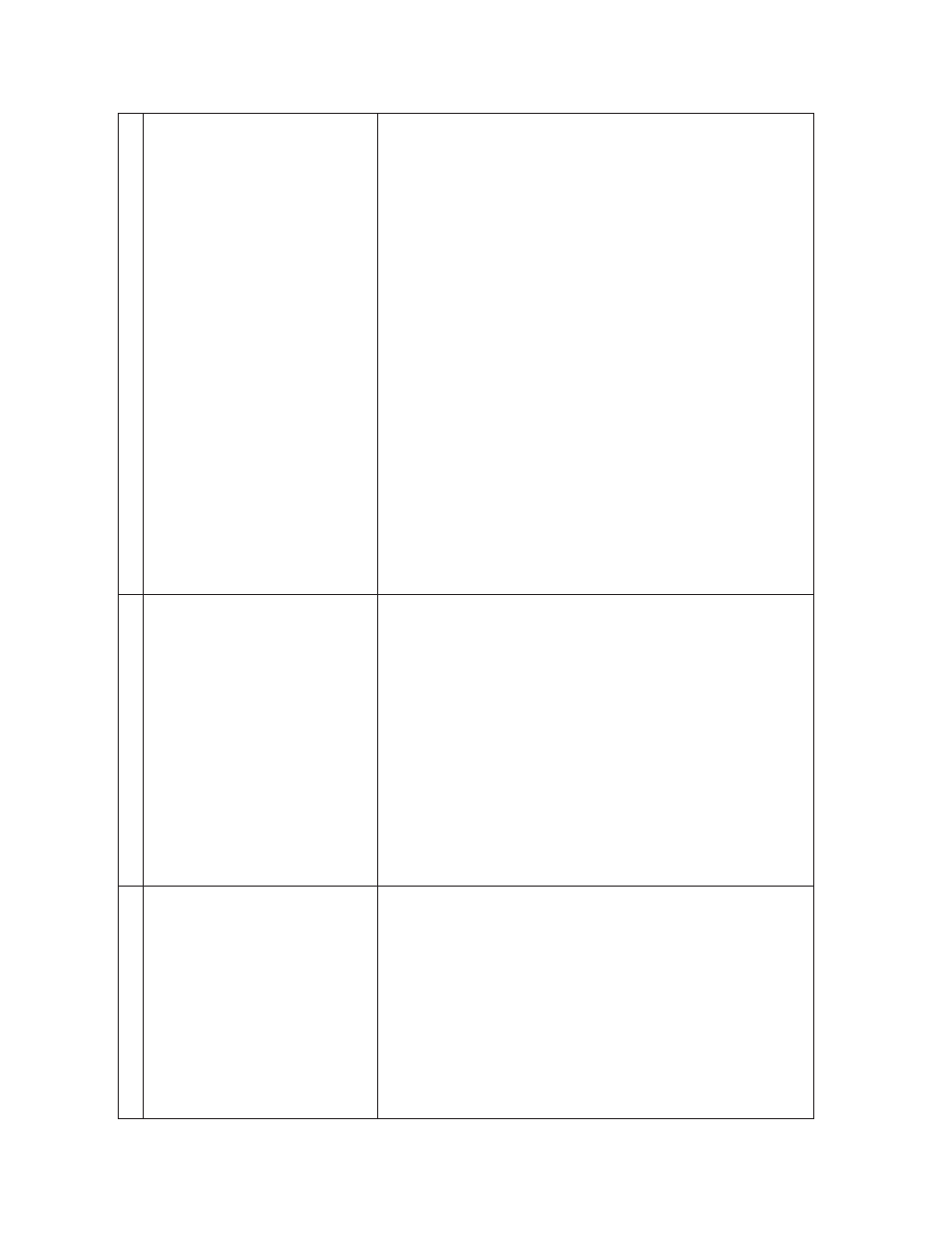

TABLE 8-1. BOILER TRO

UBLESHOOTING – Contin

ued

FAULT INDICATION

PROBABL

E CAU

SES

CORRECTI

VE ACTI

O

N

HIGH GAS

PRESSURE

1.

In

cor

re

ct

su

pp

ly

gas pr

es

su

re.

2. Defe

ctive

SSOV

Actuator

gas

pre

ssure adju

stment re

gula

tor.

3.

Defe

ctive Hig

h Ga

s Pr

es

su

re Swit

ch

4.

Gas p

re

ssure

snub

ber n

ot installe

d.

1.

Che

ck to ensure ga

s p

re

ssure at inlet of SSOV is 2 psig

maximum.

2.

If gas sup

ply pre

ssure do

wnstre

am of the SSOV cann

ot be

lowe

red, to 1.8” W.

C. (se

e para. 4.3, ste

p 10), the SSOV

Actuator g

as

pre

ssure adju

stm

ent re

gula

tor may be de

fective.

3.

Remove the l

ead

s from the

high ga

s pre

ssure

swit

ch

and

measure co

ntinuity acro

ss the com

m

on a

nd normally close

d

terminals

with the unit not fi

ring. R

eplac

e the s

w

itch if it does

not

sho

w

continui

ty.

4.

See Figure 8-1. Ensure tha

t the gas pressure sn

ubb

er

is

installe

d at the high ga

s pressure switch

.

HIGH WATE

R

TEMP

SWITCH OP

EN

1.

Faulty

Water temperature swit

ch.

2.

Inc

orrec

t PID s

ettings

.

3.

Faulty shell tempe

rature sensor.

4.

Unit in Manu

al mode

5.

Unit s

etpoint is

greater than Over

Tempe

ratu

re Switch setpoi

nt.

6.

Bo

ile

r Ma

na

ge

me

nt

Sys

tem PID

o

r

other settings not corre

ctly setup.

7.

No interlock

to boiler or BMS to

disa

ble boile

r(s) in event that system

pump

s have failed.

8.

System flow rate cha

nge

s

are

occurrin

g fast

er than boil

ers ca

n

respon

d.

1.

Test the temp

eratu

re switch to in

su

re it trips

at its

ac

tu

al water

temperature setting.

2.

Che

ck PID se

ttings agai

nst

Menu D

efault s

ettings

in the

Appendix. If the setting

s h

ave been

cha

nged, re

co

rd

the curre

nt

readings

then res

et them

to the default values

.

3.

Usi

ng the re

si

stan

ce chart

s in the Appen

dix C, Measu

re the

resi

stan

ce of

Shell sen

so

r

and BTU

sen

sor at a

kno

w

n water

temperature.

4.

If unit is in Manual Mo

de switch to Auto

Mode.

5.

Che

ck setp

oi

nt of unit and se

tpoi

nt of Temperature S

w

itch;

Ens

ure that the temperature sw

itc

h

is

set higher than the unit’s

set

poi

nt

.

6.

Check

the BMS for c

hanges

to PID def

ault values

, correc

t as

necessa

ry.

7.

If system pu

mp is controll

ed by Energy

Manage

ment

System

other than B

M

S or pump

s are individu

al

ly controlle

d by boiler,

ch

eck

to s

ee if there are fl

ow sw

itc

hes

interlock

ed to the BMS or

boiler.

8.

If the s

ys

tem is

a variable flow

s

ys

tem, monitor s

ys

tem flow

ch

anges

to ens

ure that the rate of

flow change is

not fas

ter than

what the boil

ers

can

re

spo

nd to.