AERCO BMK 3.0 LN Natural Gas July 2011 User Manual

Page 61

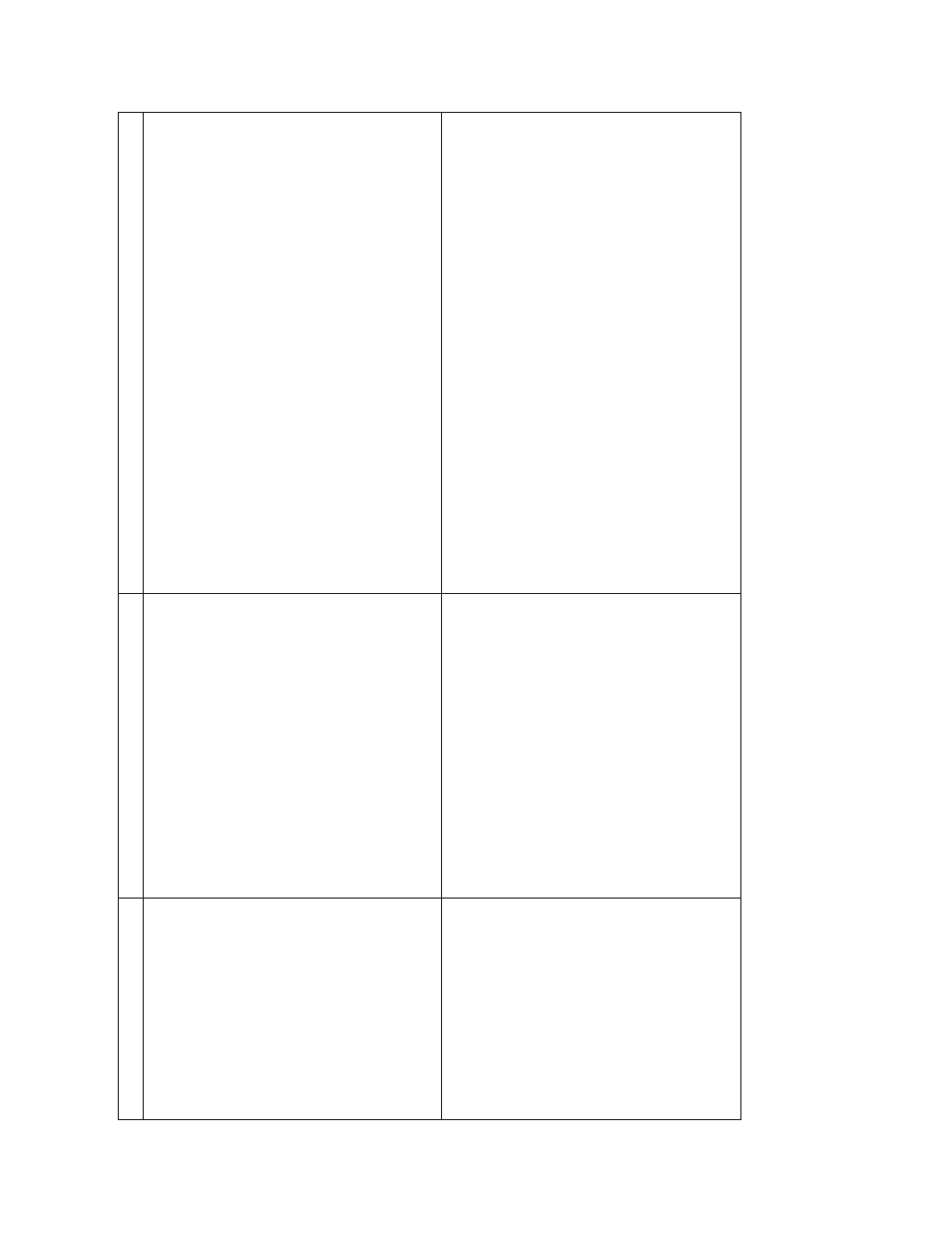

TROUBLESHOOTING

8

-

3

TABLE 8-1. BOILER TR

OUBLESHOOTING – Contin

ued

FAULT INDI

CATION

PROBABL

E CAU

SES

COR

R

ECTI

VE ACTI

O

N

AIRFLOW FAULT

DU

RI

N

G

PU

RGE

1.

Blowe

r not ru

nning o

r ru

nni

ng too slo

w

2.

Defe

ctive Air Flow Swit

ch

3.

Blocked Air flow Switch

4.

Blocked Blo

w

er inle

t or inlet duc

twork

.

5.

No voltage to

switch from control box.

6.

PROBABL

E CAU

SES

from 3 to 12

for

AI

RF

LO

W

FAUL

T D

U

R

ING

IGNITION

al

so apply for this fault

1.

Start the unit.

If the blower doe

s not

run

che

ck the

bl

owe

r

solid

state relay for input an

d output voltage. If the relay is okay,

che

ck the blo

w

er.

2.

Start the unit

. If the blower ru

ns

, c

hec

k the airflow sw

itch for

continuity. R

eplac

e the switc

h if there is no c

ontinuity.

3.

Remove the

air flow

swit

ch and in

spe

ct for sign

s of blockag

e,

clea

n or repla

ce a

s ne

ce

ssary.

4.

Inspe

ct the

inlet to

th

e comb

ustio

n blo

w

er

i

ncludi

ng

any

duct

w

ork lea

ding up to the co

mbu

stion blo

w

er f

or si

gns

of

blocka

ge.

5.

Measure for

24 VAC d

urin

g start

seq

ue

nce from e

ach sid

e of the

swit

ch to ground. If 24VAC is

not present refer to qualified

servi

ce pe

rso

nnel.

6. See

CORRECTIVE ACTION

from 3 to 12 for

AI

RFLO

W

FAU

LT D

U

RI

NG I

G

NI

TI

O

N

AIRFLOW FAULT

DU

RI

N

G

R

U

N

1.

Blowe

r stop

pe

d run

ning d

ue to thermal

or cu

rrent overloa

d

2.

Blocked Blo

w

er inlet or inl

et ductwo

rk

3.

Blocked ai

rflo

w switch

4.

Defe

ctive airflow switch

5. Comb

ustio

n

oscillation

s

6.

PROBABL

E CAU

SES

from 3 to 12

for

AI

RF

LO

W

FAUL

T D

U

R

ING

IGNITION

applies

for this

fault

1.

Che

ck

com

bustion

blo

w

er

for

sig

ns of

exce

ssive h

eat o

r hi

gh

curre

nt dra

w

that may

trip therm

al or current overl

oad

device

s.

2.

Ins

pec

t the inlet to the co

mb

ustio

n blo

w

er

i

ncludi

ng

any

duct

w

ork lea

ding up to the co

mbu

stion blo

w

er f

or si

gns

of

blocka

ge.

3.

Remove

the

airflow switch an

d in

sp

ect for

sign

s

of blo

ckage,

clea

n or repla

ce a

s ne

ce

ssary.

4.

Measure the

airflow

switch fo

r

continuity w

ith the c

ombus

tion

blower runni

ng. If there is an e

rratic resi

stan

ce rea

ding o

r the

resi

stan

ce

re

ading i

s gre

ater than

zero ohms, repla

ce the swit

ch.

5.

Run

unit

to f

ull fire. If th

e unit

rum

bles or run

s

rou

gh, pe

rform

comb

ustio

n calibratio

n.

6.

PROBABL

E CA

USE

S

from

3 to

12 for

AI

R

F

L

O

W FA

ULT

DU

RI

N

G

IG

N

ITI

ON

applies for this

fault