Troublesho oting – AERCO BMK 3.0 LN Natural Gas July 2011 User Manual

Page 68

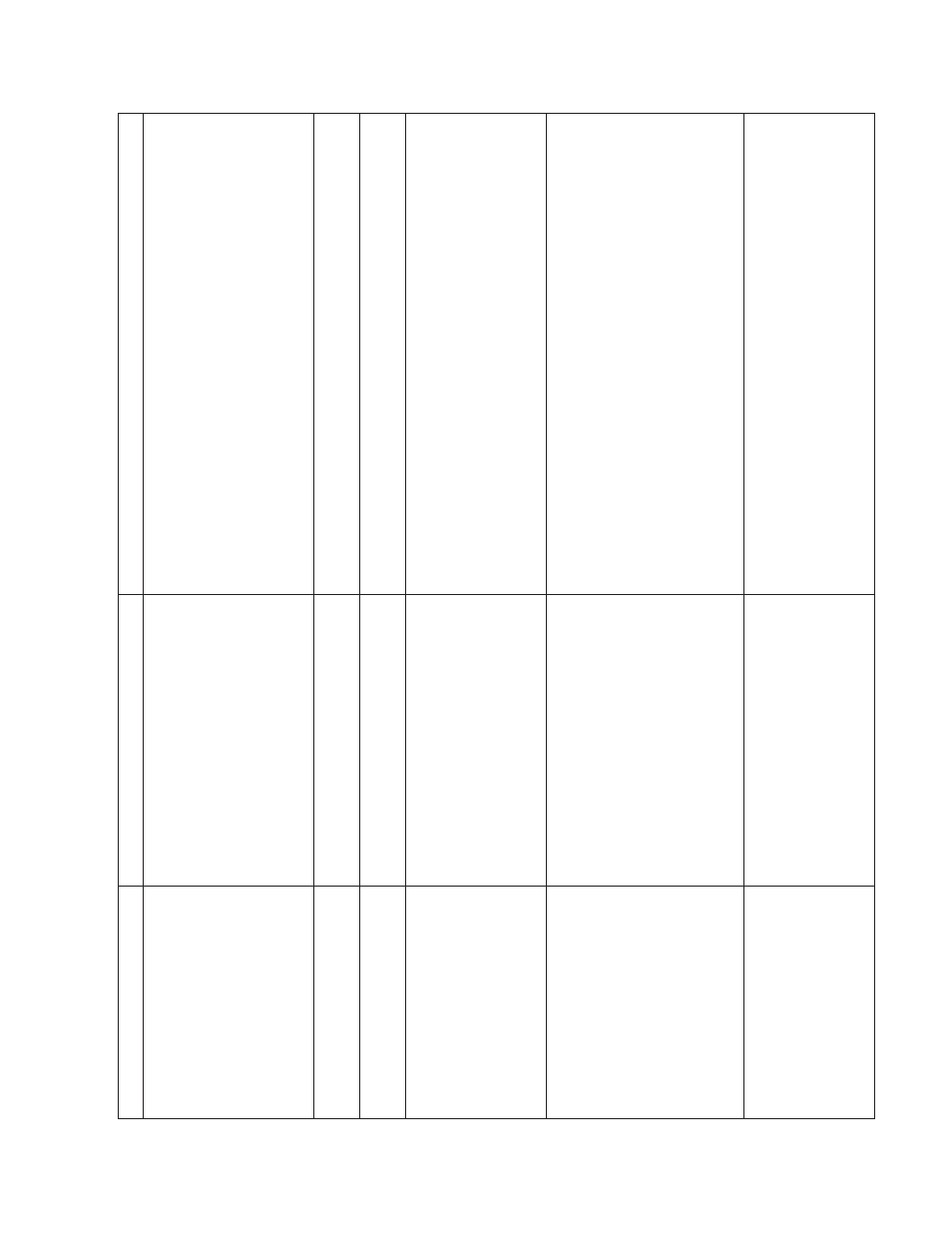

TROUBLESHO

OTING

8-10

TABLE 8-1. BOILER TRO

UBLESHOOTING – Contin

ued

FAULT INDICATION

PROBABL

E CAU

SES

CORRECTI

VE ACTI

O

N

RESIDUAL

FLAME

1.

SSOV not fully closed.

2. Defe

ctive

Flame

Dete

ctor

1.

Check

open/clos

e indicator wi

ndow of Safety Shut-Off Valve

(SSOV) and ensure that the SSO

V is

fully c

los

ed. If n

ot fully

clo

sed, re

pla

ce the valve and or a

ctuat

or.

Clo

se ga

s sh

ut-off valve down

stre

am of

SSOV. Install a

manom

eter o

r gaug

e in a g

as test po

rt b

etwee

n the SSOV and

the gas

s

hut

off valve.

If a

gas

pr

es

su

re

r

ea

din

g is

obs

er

ved

repla

ce the S

S

OV valve and or act

uator.

2.

Repl

ace Fla

m

e Dete

ctor.

SSOV FAULT

DU

RI

N

G

PU

RGE

See SSOV SWITCH OPEN

SSOV FAULT

DU

RI

N

G

R

U

N

1.

SSOV swit

ch

clo

sed

f

or

15

s

ec

ond

s

durin

g ru

n.

1.

Repl

ace or a

djust micro

swi

tc

h in SSOV ac

tuator. If fa

ult

persist

s, repl

ace a

ctuato

r.

SSOV RELAY

FAILURE

1.

SSOV relay failed on b

oard.

2. Floating

Neut

ral.

3.

Hot and

Neut

ral reve

rsed a

t SSOV.

1.

Press CLEAR button an

d resta

rt un

it. If

fault pers

is

ts, replace

Ignition/Stepp

er (IGST

) Board.

2.

The Ne

utral a

nd Earth G

ro

und

are not conne

cted at the so

urce

and therefore

there is a vol

tage mea

su

re

d betwe

en th

e two.

Normally this

measurement

shoul

d be ne

ar ze

ro o

r no

more tha

n

a few millivolts.

3.

Che

ck SSOV powe

r wi

ring

.

SSOV

SWITCH OP

EN

1.

Actuator n

ot allowin

g for full clo

sure

of gas valve

2.

SSOV powe

red wh

en it sh

ould not

be

3.

D

efec

tive Switc

h or Ac

tuator

4.

Inc

orrec

tly wired switch.

1.

Observe op

eration of the Safe

ty Shut-Off Valve (SSOV) through

indicator on t

he Valve actu

ator and e

nsu

re that the valve is fully

and not pa

rtia

lly closin

g.

2.

If the SSOV n

ever c

los

es

, it may be powered

co

ntinuous

ly.

Clo

se the ga

s supply an

d remove po

we

r from the unit. Refer

fault to qualified se

rvice p

er

so

nnel.

3.

Remove the

electri

cal

cov

er from the S

S

OV and ch

eck swit

ch

continuity. If

th

e switc

h does

not s

how

co

ntinuity w

ith the gas

valve closed, either adj

ust

or re

pla

ce the

switch or a

ct

uator.

4.

Ens

ure that the SSOV Proof of Clos

ure

sw

itc

h is

c

orrec

tly wired.

STEPPER MOTOR

FAILURE

1.

Air/Fuel Valve out of calibration.

1.

Refer to GF-112 and perform

Stepper Te

st (pa

ra. 6.3.5) to

ensure

stepp

er moto

r rotat

es prope

rly b

etwee

n the 0

%

(fully

clo

sed

) and 1

00% (fully op

en) po

sition

s.

Verify that th

e

VALVE

POSITION b

arg

rap

h and t

he dial on the

Air/Fuel Valve track

each other to

indicate pro

pe

r ope

ratio

n. If operation is not

co

rr

ec

t, p

er

for

m th

e Ste

ppe

r F

eed

ba

ck

C

alibr

at

io

n

(G

F

-11

2,

para. 6.2.1

).