Error displays and corrective actions, Teq, T#p)g – KEYENCE IG Series User Manual

Page 8: Ttq, Ttf, Tt5, Basic functions 1. measurement mode, Measurement direction, Averaging (response time), Output method

8

Basic functions

1. Measurement mode

Setting the position to measure.

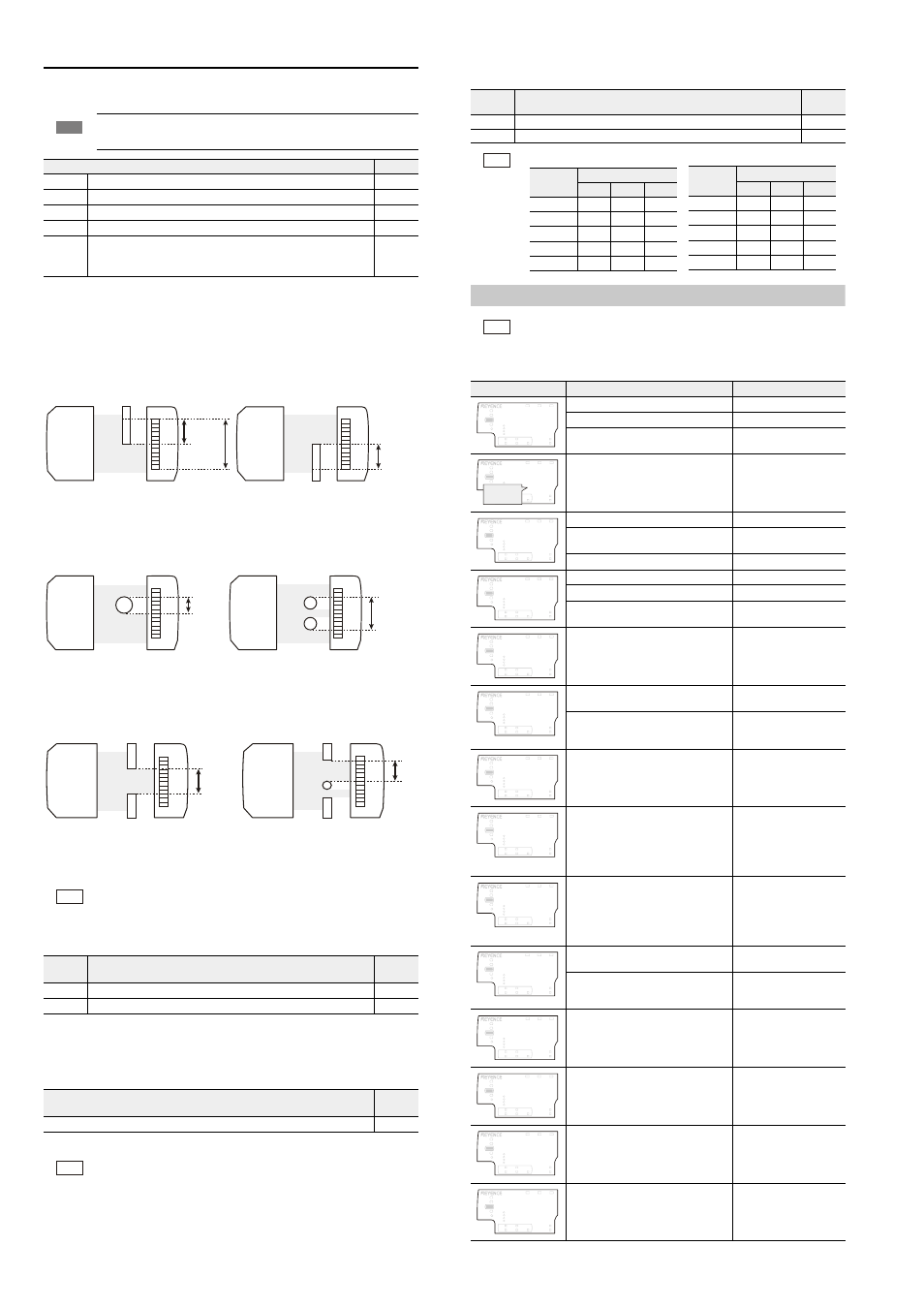

z Edge control/Positioning mode

When the measurement direction [

VQR] (top) is selected, the distance from the top edge of the

measurement range to bottom side of the measured target is the R.V. (internal measurement

value). When [

DVO] (bottom) is selected, the distance from the bottom edge of the measurement

range to the top side of the measured target is the R.V. (internal measurement value).

If there is no measurement target, R.V. (internal measurement value) will display [

].

z Outer diameter/Width measurement mode

The distance from the top edge of the target closest to the top of the measuring range to the

bottom edge of the target closest to the bottom of the measuring range will be calculated as

the R.V. (internal measurement value). If there is no target present, the R.V. (internal

measurement value) will display [

].

z Inner diameter/Opening measurement mode

The distance from the bottom edge of the target closest to the top of the measuring range to

the top edge of the next target near the bottom of the measuring range will be calculated as

the R.V. (internal measurement value).

If there is no target present, the R.V. (internal measurement value) will display [

].

z Glass edge mode

This operation is the same as that for the Edge control/Positioning mode, however the

measurement sensitivity is increased.

2. Measurement direction

Setting the measurement direction of the master workpiece to the sensor head.

3. Averaging (Response time)

The response time is the time from when the sensor head starts the measuring operation to the point where

the output signal is sent. When the average number of times is increased, the response time becomes

longer, but the R.V. (internal measurement value) and P.V. (judgment value) will be more stable.

4. Output method

Setting the judgment output method

Error Displays and Corrective Actions

Note

At the point when the selection is switched on the setting display, it is

reflected to the R.V. (internal measurement value).

Measurement mode

Default value

C.GFI

Edge control/Positioning mode,

c

D.FKC

Outer diameter/Width measurement mode

E.KPU

Inner diameter/Opening measurement mode

F.INU

Glass edge mode

G.RQU

to

J.WUT

Pin position measurement mode, Pin interval judgment mode,

Pin diameter judgment mode, Specified edge interval measurement

mode

Reference

For details of other measurement modes, see the User’s Manual.

Setting

value

Description

Default

value

VQR

Measures the distance from the top side of sensor head to the specified edge.

c

DVO

Measures the distance from the bottom side of sensor head to the specified edge.

Setting range

Default

value

JUR / / / / / / / / / / / /

Reference

• The response time for [

JR] (High speed) is 1.96 ms.

• 1 indicated in [

] means the average number. The response time can be calculated

256 times or less: Response time = Number of times for averaging x 0.98 + 2.94 ms

512 times or more: Response time = Number of times for averaging ÷ 256 x 257 x 0.98 + 1.96 ms

• When “Pin interval judgment mode” or “Pin diameter judgment mode” is

selected in “1. Measurement mode”, the setting range and the response

time will differ.

Measurement

range

R.V.

Top

Bottom

Top

Bottom

R.V.

Top

Bottom

Top

Bottom

When the measurement direction is [6Q2] When the measurement direction is [$6/]

R.V.

R.V.

Top

Bottom

Top

Bottom

Top

Bottom

Top

Bottom

R.V.

R.V.

Top

Bottom

Top

Bottom

Top

Bottom

Top

Bottom

Setting

value

Description

Default

value

PQ

Output is normally open

c

PE

Output is normally closed

Reference

Reference

"4. Output format" (page 8)

• The edge check output operates regardless of the error.

• When [

GTE] is displayed, all the outputs will turn OFF.

• When an error is displayed, the analog voltage output will be 5.5 V and

analog current output will be 3.0 mA.

Error indication

Error

Actions

The transmitter and receiver are not connected.

Connect the transmitter and receiver.

The transmitter and receiver are broken. Replace the transmitter and receiver.

The sensor head cable of the transmitter

and receiver is disconnected.

Replace the sensor head

cable.

The transmitter and receiver are

reversely connected to the amplifier.

Connect the transmitter

and receiver correctly.

The receiver is not connected.

Connect the receiver.

The receiver is broken.

Replace the transmitter

and receiver.

The sensor head cable of the receiver is disconnected

Replace the sensor head cable.

The transmitter is not connected.

Connect the transmitter.

The transmitter is broken.

Replace the transmitter and receiver.

The sensor head cable of the

transmitter is disconnected.

Replace the sensor head

cable.

The laser of the transmitter has been

damaged.

Replace the transmitter and

receiver.

Reading/writing the nonvolatile memory

(EEPROM) storage data failed.

Turn the power on again.

Data has been written in the nonvolatile

memory (EEPROM) over 500 thousands

times and malfunction occurred.

Replace the transmitter

and receiver.

The transmitter and receiver type

(Measurement range) do not match.

Replace with the same type

(measurement range) of the

transmitter and receiver.

The standard waveform was not

registered properly.

Do not turn off the sensor head

or disconnect it from the sensor

amplifier while registering the

standard waveform.

Register the standard waveform

again.

Overcurrent was detected on the

output.

• Check the load and

reduce the current to

within the rated range.

• Check that the output

wire does not touch

another wire or a frame.

Reading/writing the nonvolatile memory

(EEPROM) storage data failed.

Turn the power on again and

perform the initial reset.

Data has been written in the nonvolatile

memory (EEPROM) over 1 million times

and malfunction occurred.

Replace the amplifier unit if

data writing is necessary.

Communication is not possible

between the amplifiers.

Turn the power on and check

the connection status

between amplifiers.

The light-receiving amount is too large

to register the standard waveform.

Check whether too much

ambient light or light from

another sensor enters the

receiver or not.

The light-receiving amount is too small

to register the standard waveform.

• Align the optical axis so

the optical axis alignment

indicator lights up.

• Clean the sensor head's

transmitter and receiver.

The standard waveform cannot be

registered because the receiver is

receiving the laser light of the

transmitter from another amplifier.

Use the transmitter and

receiver associated with

their designated amplifier.

Normally open [

PQ]

judgment

judgment output

HIGH

GO

LOW

HIGH

ON

OFF

OFF

GO

OFF

ON

OFF

LOW

OFF

OFF

ON

[

]

OFF

OFF

OFF

Error

ON

OFF

ON

Normally closed [

PE]

judgment

judgment output

HIGH

GO

LOW

HIGH

OFF

ON

ON

GO

ON

OFF

ON

LOW

ON

ON

OFF

[

]

ON

ON

ON

Error

OFF

ON

OFF

V T

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

T V

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

Displayed

alternately.

T

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

V

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

.#5'4

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

4''2

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

T#P)G

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

#.K)P

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T%

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T'

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'TEQ/

GO

HOLD

CALC

CHECK

'TTQ

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#.K)P

GO

HOLD

CALC

CHECK

'TTF

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#.K)P

GO

HOLD

CALC

CHECK

'TT5

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#.K)P

GO

HOLD

CALC

CHECK