Optical axis alignment, Setting the tolerance setting value (threshold), Automatic setting (tolerance tuning) – KEYENCE IG Series User Manual

Page 6: Automatic setting (2-point tuning), Z sub display, Reference

6

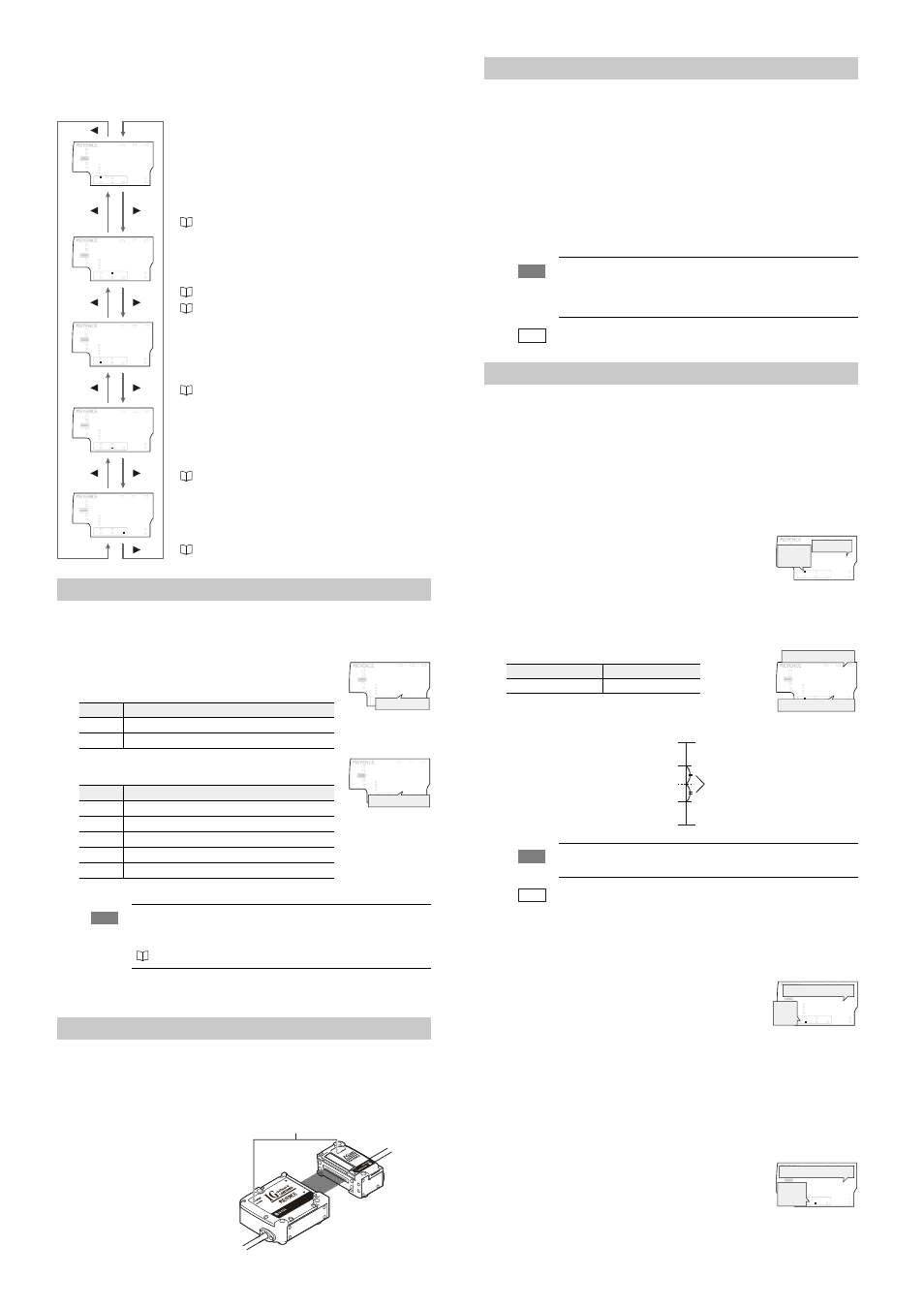

z Sub display

The sub display switches each time the

W/X button is pressed. According to the type of

displayed value selected, the sub display identification indicator will show one of the

following: [R.V. / ANALOG / HI / LO / SHIFT]

Operation When the Power is Turned on for the First Time

When the amplifier is turned on for the first time after the sensor head is connected, the initial setting

display appears. Make the initial setting according to the following procedure as this is necessary for

both the main unit and the expansion units when units are added.

1

Press the

S/T button to select the polarity of the signal

output and the edge check output and press the [MODE]

button.

2

Press the

S/T button to select the analog output method and

press the [MODE] button.

After the setting is complete, [

GPF] blinks several times on the sub display and changes to the basic display.

3

Perform “Optical Axis Alignment” and “Standard Light-Receiving Amount Registry” (page 6).

Make other settings as necessary.

Optical Axis Alignment

If the optical axis alignment indicators [ALIGNMENT] of transmitter, receiver and amplifier do not both

light up upon power up, align the optical axis of the sensor head.

Adjust the angle of the transmitter and receiver while a target object is not present within

the measuring range. Then fix mount the transmitter and receiver once the alignment

indicators [ALIGNMENT] light up.

Registering the standard waveform (Gain adjustment)

The measurments will be stabilized once the standard waveform has been registered. (Gain adjustment)

The total light received will be registered as 100%.

Register the standard waveform when the unit is used for the first time, when the setting

environment is changed, or when the measurement sensitivity is changed. For details, refer to

the User’s Manual.

1

Confirm that the optical axis alignment indicators [ALIGNMENT] of the transmitter,

receiver and amplifier are lit up.

If the optical axis adjustment indicators are off, align the optical axis.

2

Press the [MODE] and [SET] buttons at the same time for approx. 2 seconds on the

basic display.

[

CNKIP] is displayed on the main display (upper level) and the standard waveform will

be registered. The basic display will be restored when the registry is complete.

Setting the Tolerance Setting Value (Threshold)

There are two types of tolerance setting values: HIGH (upper limit) and LOW (lower limit) The

value displayed will output its signal as one of the following 3 levels: When the value exceeds the

upper limit (HIGH); when the value is within the tolerance range (GO); and when the value falls

below the lower limit (LOW)

"4. Output format" (page 8)

Automatic setting (Tolerance tuning)

When the object to be measured is present, and the measurement value for the master

workpiece is set, the HIGH (upper limit) and LOW (lower limit) will be automatically set with

the master workpiece measurement value centered.

1

Press the

W/X buttons several times on the basic display.

Then display the R.V. (internal measurement value) on the

sub display (lower level).

2

Measure the master workpiece and press the [SET] button.

The P.V. (judgment value) will be set as a standard value for

the tolerance settings.

[

UGV] and the tolerance setting width are displayed alternately on the sub display

(lower level).

3

Press the

S/T buttons to set the tolerance width and press the [SET] button.

After [

UGV] blinks several times, the display returns to the R.V.

(internal measurement value).

The tolerance tuning is complete.

Automatic setting (2-point tuning)

The following will explain how to set up a mean tolerance level that distinguishes between

acceptable vs. defective targets.

1

Press the

W/X buttons several times until the HIGH tolerance

value on the sub display (lower level) is shown.

2

Place the acceptable target within the measuring range and

press the [SET] button.

The R.V. (internal measurement value) will be registered and

[

JKUGV] will be shown on the main display (upper level).

3

Now place the defective target within the measuring range and press the [SET] button.

The R.V. (internal measurement value) will be registered and after [

UGV] blinks on the

main display (upper level), the P.V. (judgment value) will be shown.

On the sub display (lower level), the medium value between the acceptable target

value registered in step 2 and the HIGH side defective target value will now be

displayed.

The HIGH tolerance value (upper limit) is now setup.

4

Press the

X button once and display the LOW tolerance value

on the sub display (lower level).

5

Measure the acceptable target again and press the [SET]

button.

The R.V. (internal measurement value) is now registered.

[

NQUGV] will be shown and on the main display (upper level).

R.V. (internal measurement value)

The actual measurement value for the object is displayed.

This displayed value is not held.

• With the pin size judging mode or pin interval judging mode,

the R.V. (internal measurement value) for each pin size and

each pin interval can be displayed.

“1. Measurement mode” (page 8)

The analog output will only be displayed for the main unit and

only when it is enabled.

The voltage value (unit: V) or current value (unit: mA) of the

analog output is displayed.

“Operation When the Power is Turned on for the First Time” (page 6)

“Initial Reset (Initialize)” (page 7)

HIGH side setting value

The upper limit of the acceptable range (tolerance setting value) for

the object that is being measured is displayed. Also, the setting

value can be changed. If the P.V. (judgment value) exceeds the

value set here, the HIGH output signal will be sent.

“Setting the Tolerance Setting Value” (page 6)

LOW side setting value

The lower limit of the acceptable range (tolerance setting value)

for the object that is being measured is displayed. Also, the

setting value can be changed. If the P.V. (judgment value) falls

below the value set here, the LOW output signal will be sent.

“Setting the Tolerance Setting Value” (page 6)

Shift target value

When the zero shift button is pressed or the zero shift input is

set to ON, the R.V. (internal measurement value) will be

matched to the value set here.

“Zero shift function” (page 7)

Setting value

Description

PRP

NPN output

RPR

PNP output

Setting value

Description

QHH

Not output

W

Analog output after the judgment value is converted to the range from 0 to 5 V.

W

Analog output after the judgment value is converted to the range of ±5 V.

W

Analog output after the judgment value is converted to the range from 1 to 5 V.

CORT

Analog output after the judgment value is converted to the range from 4 to 20 mA.

Note

The initial setting display appears only when the power is turned on for the

first time. It will not appear when the power is turned on the second time or

thereafter. To change the initial setting, perform the initial reset.

“Initial Reset (Initialize) page 7”

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD

CALC

CHECK

GO

GO

HOLD

CALC

CHECK

X

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

GO

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD

CALC

CHECK

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

PRP

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

QWV

GO

HOLD

CALC

CHECK

Output polarity

QHH

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#P.)

GO

HOLD

CALC

CHECK

Analog output

Transmitter

Receiver

Optical axis alignment indicator [ALIGNMENT]

Note

If attempting to register the standard waveform while the optical axis

alignment indicators [ALIGNMENT] are off, an error message will be

displayed and the standard waveform cannot be registered.

“Error message and countermeasures” (page 8)

Reference

The standard waveform can be registered by the external input as well.

Select the "Gain input" for the external input 4 (purple wire).

Setting range

Default value

0.000 to 99.999

0.100

Note

The tolerance tuning cannot be performed when the P.V. (judgment

value) is displayed as [

].

Reference

When the tuning result exceeds the setting range (-99.999 to 99.999), the

limit values of the setting range become the High and Low tolerances.

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD

CALC

CHECK

GO

R.V. value

[R.V.]

lights up.

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

Tolerance setting width

Master work P.V.

Tolerance tuning setting width

Measurement upper limit value

Measurement lower limit value

LOW tolerance value (lower limit)

Master workpiece P.V. (judgment value)

HIGH tolerance value (upper limit)

GO

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD

CALC

CHECK

[HI]

lights up.

HIGH tolerance value

GO

HOLD

CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

LOW tolerance value

[LO]

lights up.