Tools, Torques, Required tools miscellaneous sockets – Cub Cadet T2-HP User Manual

Page 19: Required torque values

T2

®

15

TOOls

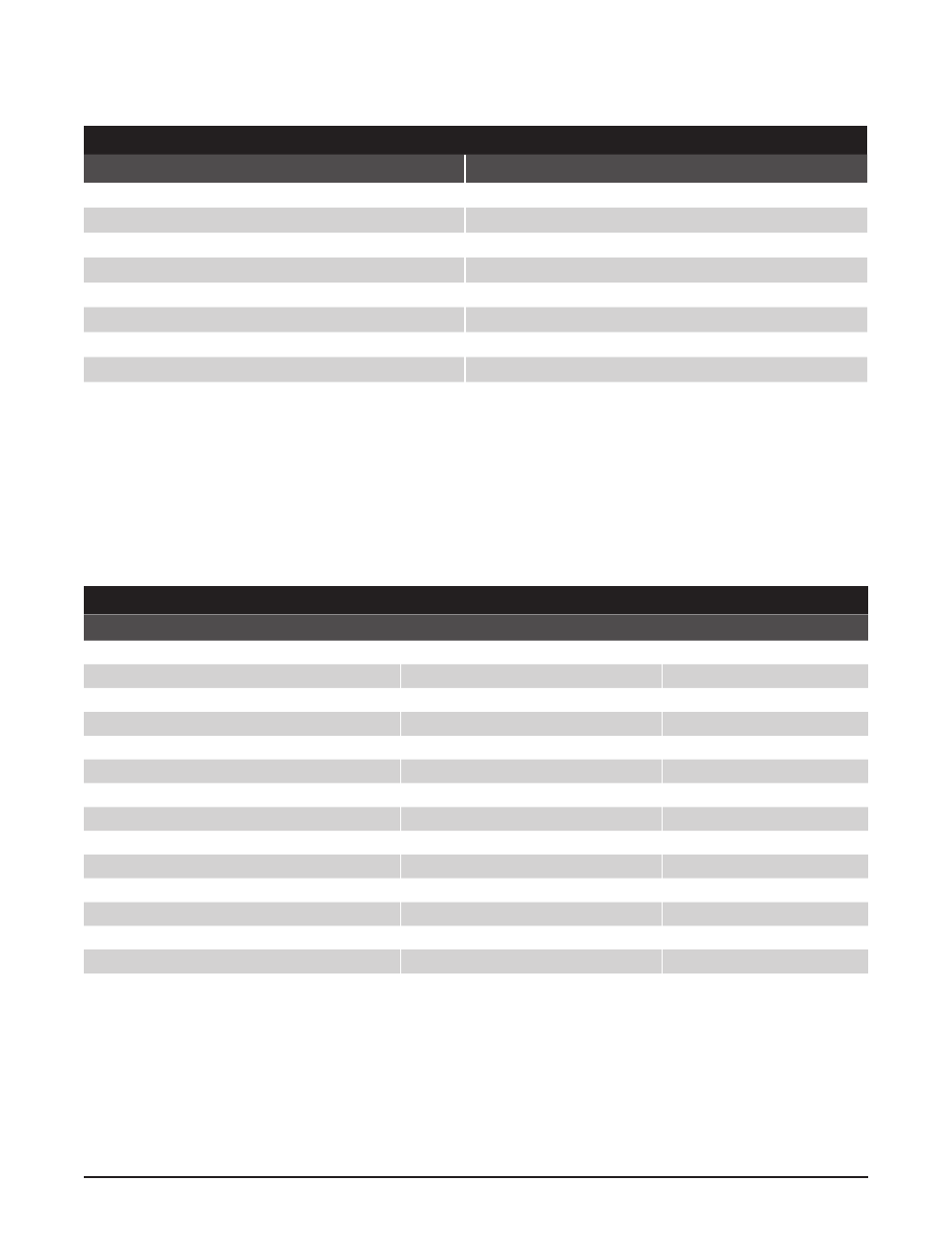

As a general rule, use the low end of the torque spec on fasteners when reassembling the unit.

TOrQues

reQuIred TOOls

miscellaneous

sockets

Flat Blade Screw Driver (2)

1/2”-3/8” Adapter

Torque Wrench

1/2” Deep

Air Impact Wrench

7/16” Deep

Rubber or Neoprene Mallet

3/4” Deep

Breaker Bar

7/8” Deep

Side Cutters/Snips

9/16” Deep

Needle Nose Pliers

T-40 Torx Head

Large External Snap Ring Pliers

10 mm

Small Internal Snap Ring Pliers

reQuIred TOrQue Values

Item description

Torque

Operation

8

HFHCS 1/4-20 x 1 .25

105-155 in-lbs [11 .8-17 .5 Nm]

Housing screw

13

Plug 9/16-18 (Metal)

180-240 in-lbs [20 .3-27 .1 Nm]

Fill plug

22

Bolt, Hex Flange, 3/8-16, CS

525-700 in-lbs [59 .3-79 .1 Nm]

Center section bolt

24

Check plug

280-400 in-lbs [31 .6-45 .2 Nm]

Check plugs

25

Check plug

280-400 in-lbs [31 .6-45 .2 Nm]

Check plugs

41

TWHCS 5/16-18 x 1

230-310 in-lbs [25 .9-35 .0 Nm]

Trunnion arm screw

43

Screw, set 5/16-24 x 2 .50

135-155 in-lbs [15 .2-17 .5 Nm]

Control arm stud

49

Nut, hex 5/16-24 nylon insert

85-120 in-lbs [9 .6-13 .5 Nm]

Friction Pack Nut

127 HFHCS 1/4-20 x 2 .0 w/ patch

80-120 in-lbs [9 .0-13 .5 Nm]

Brake yoke screw

128 HHCS 1/4-20 x 1 (patch)

80-120 in-lbs [9 .0-13 .5 Nm]

Brake yoke screw

140 5/16 SAE, 5/32 tube

96-120 in-lbs [10 .8-13 .5 Nm]

Expansion tank fitting

144 Bolt, self-tapping 10-32 x 0 .5

25-40 in-lbs [2 .8-4 .5 Nm]

Expansion tank screw

152 Nut, Hex Lock 1/2-20

360-520 in-lbs [40 .7-58 .8 Nm]

Fan Nut

153 HFHCS 1/4-20 x 0 .75

50-80 in-lbs [5 .7-9 .0 Nm]

Fan Screws

162 Screw, Hex Flange Head

85-120 in-lbs[9 .6-13 .5 Nm]

Neutral Assy Arm Screw