BUCHI Inert Loop B-295 User Manual

Page 64

8 Troubleshooting

64

B-290 Operation Manual, Version I

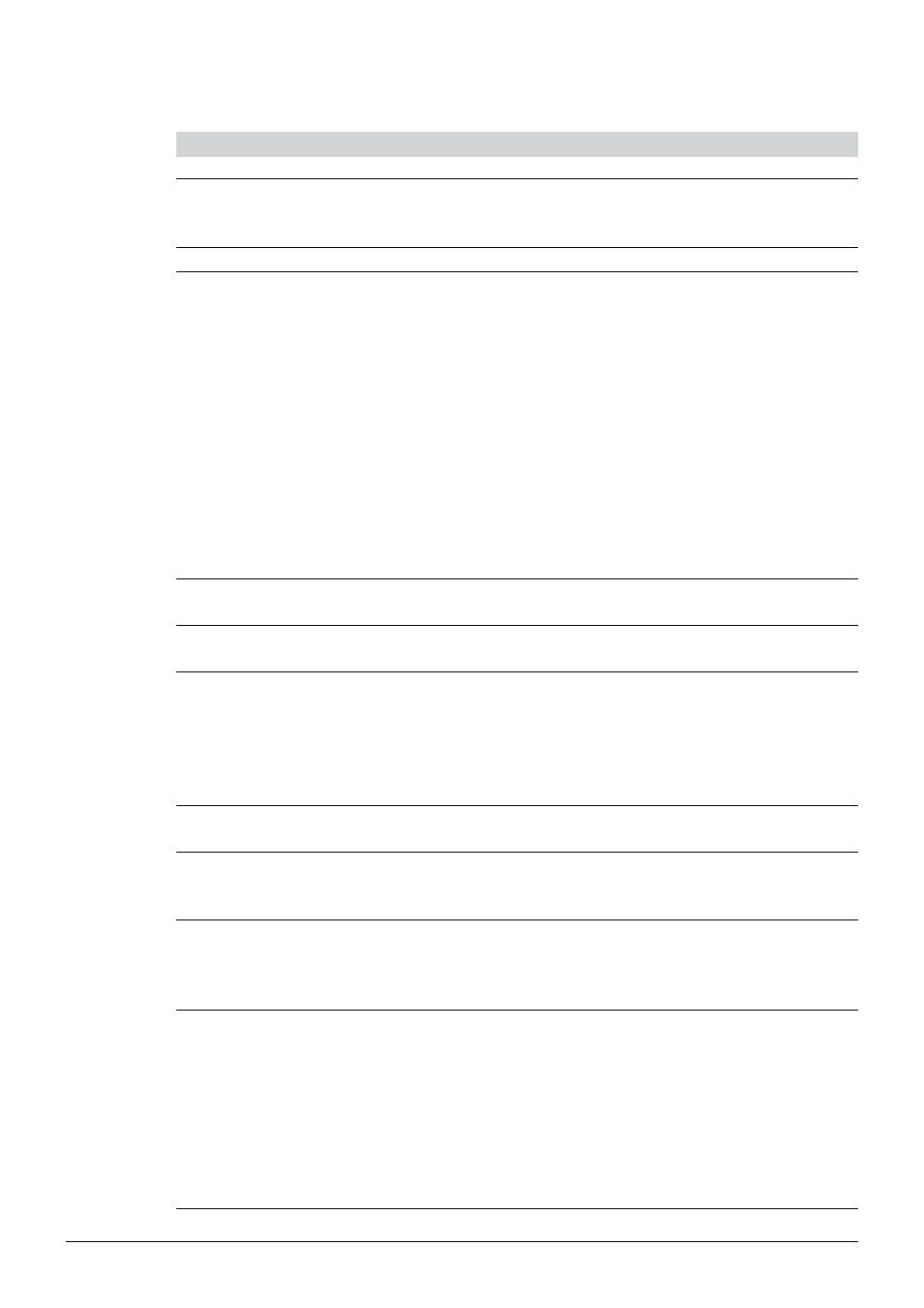

Table 8-2: Malfunctions and their remedy (cont.)

Malfunction

Possible cause

Corrective measure

Product drips in spray chamber

No spray flow

Insufficient spray flow

Open compressed air valve

Inspect pressure of air in the supply

tube (5–8 bar)

Insufficient aspirator performance Discharge filter blocked

Dismantle filter and clean it

Deposits on the spray cylinder

Nozzle is not clean

Nozzle is defective (bent nozzle

needle)

Product will not dry

Entry temperature is above the melting

point of the product

Product related deposits

Wide spray angle deposits droplet on

the spray cylinder wall

Completely dismantle the nozzle and

clean with water

Replace nozzle or defective element

Reduce the temperature difference

between entry and exit

Increase rate of gas spray flow

(> 600 l/h)

Reduce peristaltic pump performance

Reduce entry temperature

No action possible

Narrow the spray angle by adjusting

the spray cap position

Glass elements become wet

Peristaltic pump lever has become

loose

Tighten lever

Irregular or pulsed spraying

Leaks in the spray nozzle

Check seals in the spray nozzle and

replace if necessary

Deposits in the cyclone

Product related deposits

Static charge build-up

Product too moist

Temperature too high

No measure possible

Insert earthing cable

Increase exit temperature to dry the

product

Reduce aspirator performance to

reduce residence time of product

Exit temperature does not rise

Sensor not inserted

Fault in tubing system

Place probe in coupling element

Check tubing system

Entry temperature falls

Heating is switched off

Heater plug is unplugged

Fuse has blown

Switch on heating

Insert heater plug

Replace fuse (12.5 A)

Exit temperature falls

No heating

Spraying too powerful

Follow measures under “Fall of entry

temperature”

Reduce production rate of peristaltic

pump

Exit temperature rises

Nozzle blocked

Hose not dipped into stock solution

Change of concentration in stock

solution

No feed of product

Clean the nozzle by actuating the

cleaning button or by switching on

cleaning nozzle

Increase number of pulses for the

nozzle cleaning activity

Dip hose into product

Agitate product (magnetic agitator) to

obtain uniform concentration

Switch on peristaltic pump