4description of function, 4 .1 functional principle of the drying gas – BUCHI Inert Loop B-295 User Manual

Page 22

4 Description of function

22

B-290 Operation Manual, Version I

4

Description of function

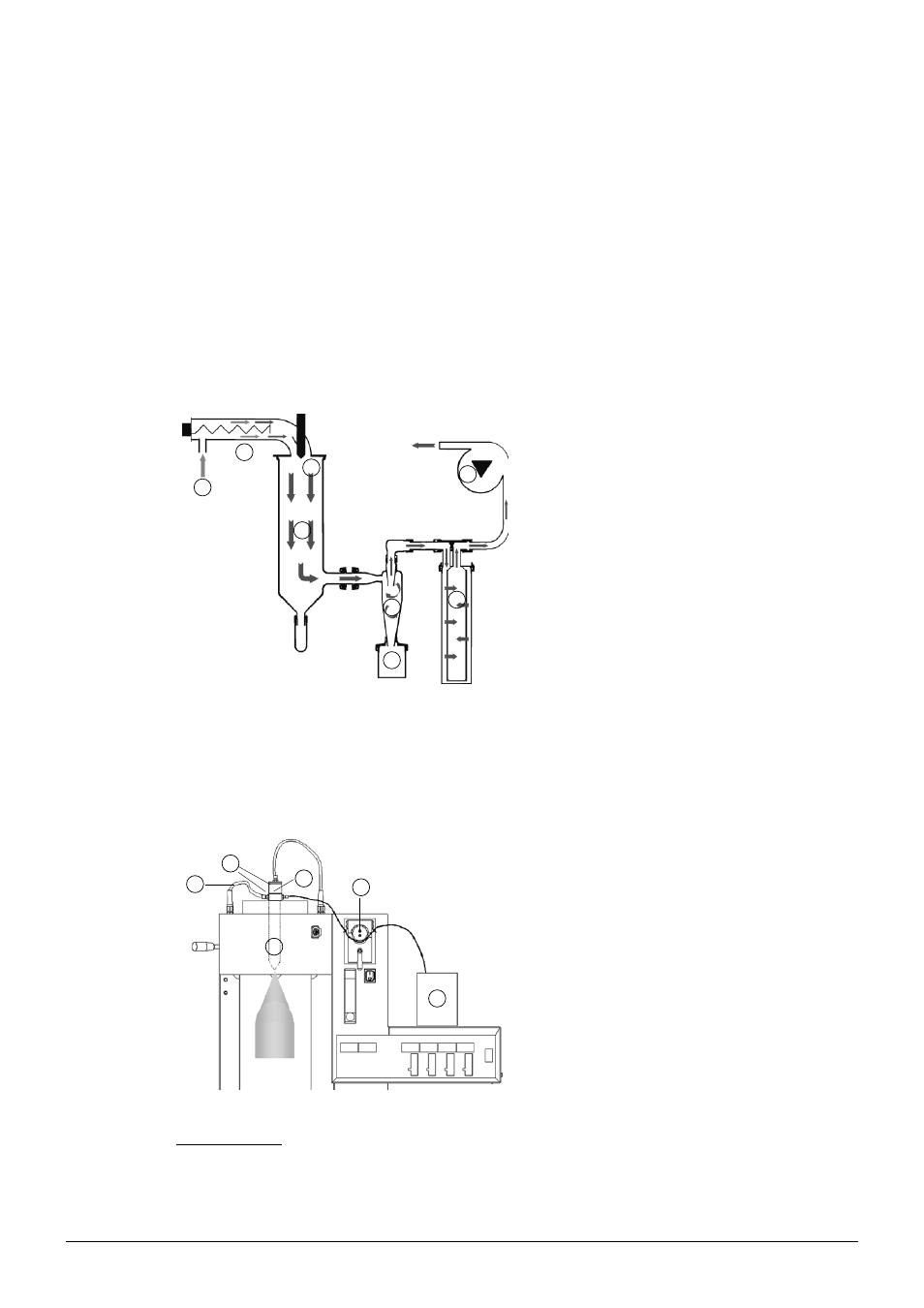

This chapter explains the basic working principle of the Mini Spray Dryer B-290 Basic (open mode

only) and the Mini Spray Dryer B-290 Advanced (for closed mode operation). It also shows how the

instruments are structured and provides a general functional description of the assemblies.

4 .1

Functional principle of the drying gas

The Mini Spray Dryer B-290 operates according to a co-current drying gas (e.g. air in open mode)

and product stream. This means that sprayed product and hot gas have the same flow direction from

downward.

5

7

1

3

4

8

2

6

a Gas inlet (optional with attached inlet filter)

b Electric heater

c Concentric inlet of the hot gas around the

spray nozzle

d Spray cylinder

e Cyclone to separate particles from gas

stream

f Product collection vessel

g Outlet filter

h Aspirator to pump gas through system

Fig. 4.1: Functional principle of the drying air

4 .2

Functional principle of the sample feed and dispersion

The Mini Spray Dryer has a integrated two-fluid nozzle: Compressed gas (normally air or N

2

) is used to

disperse the liquid body into fine droplets which are subsequently dried in the cylinder.

1

2

3

5

4

6

a Feed solution

b Peristaltic pump

c Two fluid nozzle

d Connection for cooling water

e Connection for compressed spray gas

f Automatic nozzle cleaning system

Fig. 4.2: Functional principle of the sample feed and dispersion

Spraying nozzle

The nozzle consists of the nozzle tip with a 0.7 mm dia meter hole and the nozzle cap

(1.4 or 1.5 mm in diameter). This geometry results in a mixing of fluid body and gas.