3 .3 materials used – BUCHI Inert Loop B-295 User Manual

Page 21

3 Technical data

21

B-290 Operation Manual, Version I

Table 3-7: Technical data Spray Chilling accessory (cont.)

Heating liquid

water or a thermal oil (polyethylene glycol PEG 400 with

low viscosity)

Heating liquid volume

1.4 liter

Max. melting point of sample

70 °C

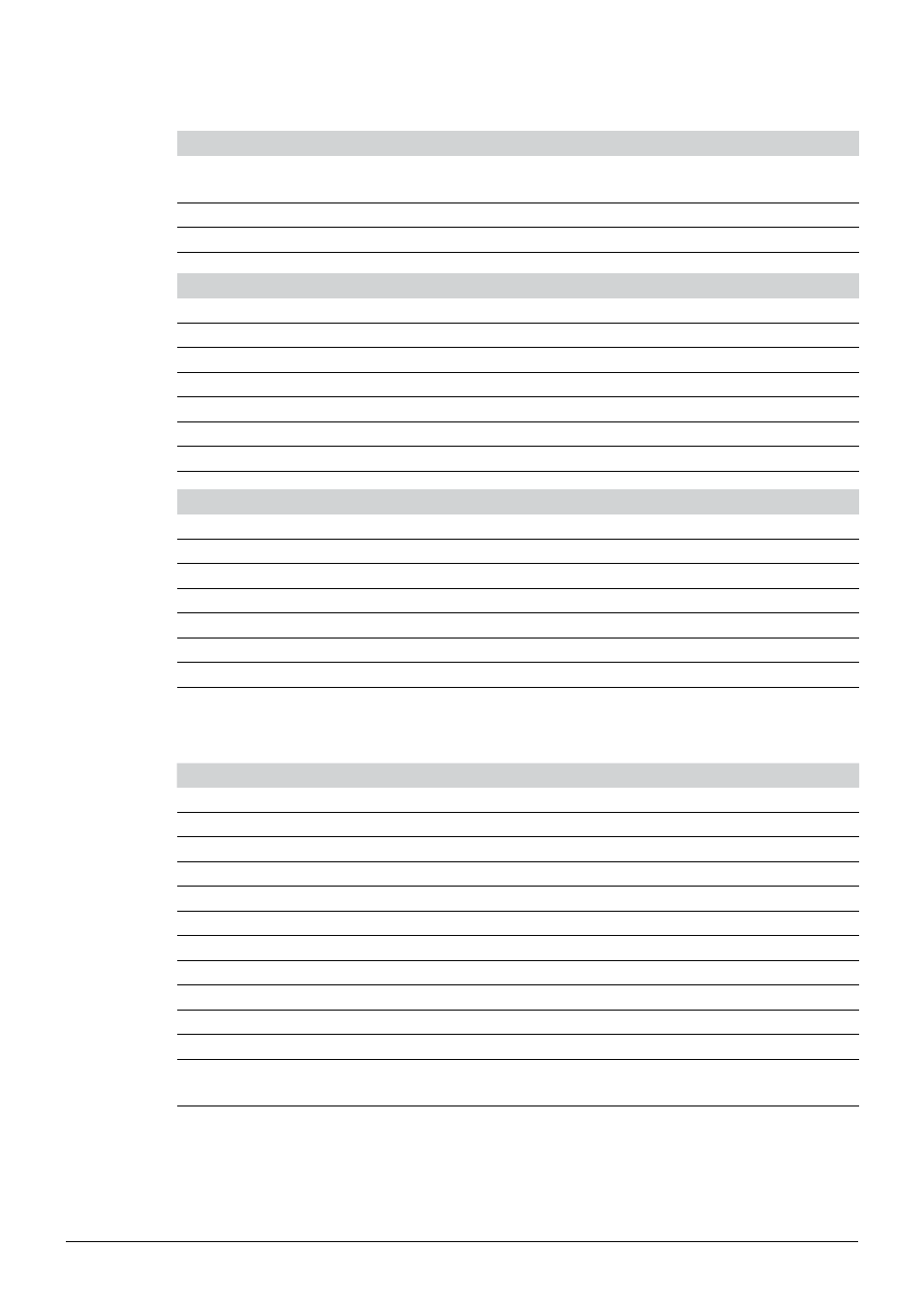

Table 3-8: Technical data Inert Loop B-295

Power consumption

max. 1400 W

Connection voltage

200-230 V ± 10 %

Frequency

50/60 Hz

Min. outlet temperature

down to –25 °C

Rate of cooling

800 W at –10 °C

Dimensions (W×H×D)

60Ч70Ч84.5 cm

Weight

88 kg

Table 3-9: Technical data Dehumidifier B-296

Power consumption

700 W

Connection voltage

200/230 V ± 10 %

Frequency

50/60 Hz

Min. outlet temperature

+ 2 °C

Rate of cooling

600 W at 0 °C

Dimensions (W×H×D)

35Ч40Ч60 cm

Weight

36 kg

3 .3

Materials used

Table 3-10: Materials used

Component

Material designation

Material code

Glass assembly

3.3 borosilicate glass

Nozzle/heater/connection piece

Stainless steel

1.4301/1.4305

Seal of product collection vessel

FPM (FFKM)

Seal cyclone/cylinder

Silicone

Preheat exchanger Inert Loop B-295

Stainless steel

1.4301

Polypress tube

EPDM

Product feed tube

Silicone and tygon

Molecular sieve bag of adsorption unit

PEEK

Acid resistant coated metal

PFA (perfluoroalkoxy polymer)

Acid resistant metal

titanium, Alloy 600

Metal parts Mini Spray Dryer B-290 acid

resistant

PFA-coated