Notice – BUCHI Inert Loop B-295 User Manual

Page 28

5 Putting into operation

28

B-290 Operation Manual, Version I

NOTE

To cut the power in case of an emergency by unplugging, the instruments or any other items

must not block the mains plug! External connections and extension lines must be provided with a

grounded conductor lead (3-pole couplings, cord or plug equipment). All used power cords must

meet the input power requirements.

Demands on the mains circuit

The mains circuit must

• provide the voltage that is given on the type plate of the instrument.

• be able to handle the load of the connected instrument(s).

• be equipped with adequat fusage and electrical safety measures, in particular proper grounding.

NOTE

Additional electrical safety measures such as residual current breakers may be necessary to meet

local laws and regulation!

External power switches (e.g. emergency stop switches) must meet IEC 60947-1 and IEC 60947-3

requirements. Such devices must be clearly labeled and accessible at any tim.

5 .3

Installing the compressed air maintenance unit and compressor (optional)

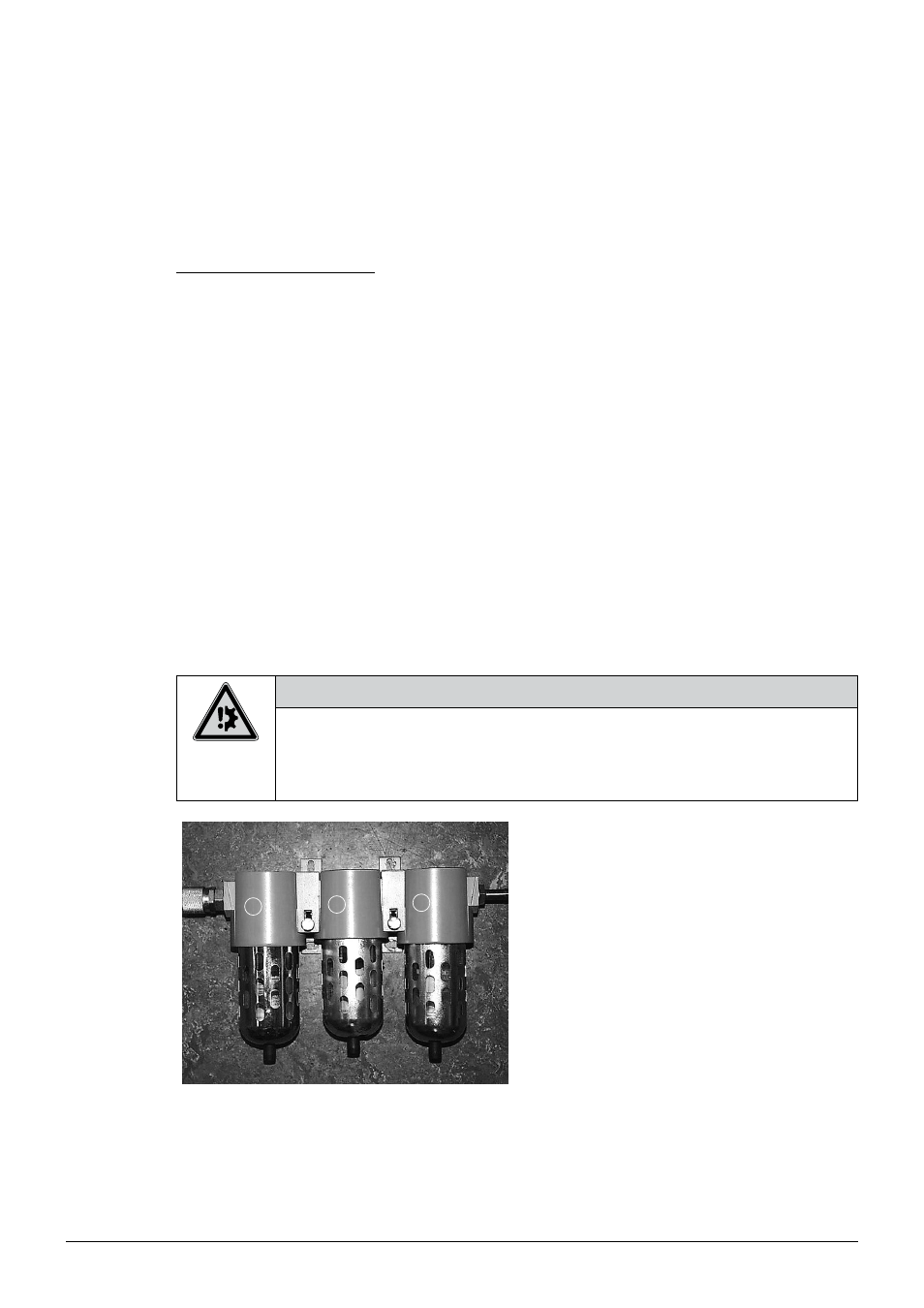

To ensure the Mini Spray Dryer B-290 achieves an optimal atomization performance, the supply of

compressed air with a pressure of 5–8 bar is necessary. The compressed air must be dried and free of

impurities (contamination of the product through impure air). If this is not guaranteed, we recommend

the use of a WILKERSON maintenance unit.

Notice

Risk of instrument damage by internal overpressure.

• External supply pressure must meet the system specifications

• Exchange clogged or defective filters immediately

• Dispose of clogged or defective filter immediately

1

2

3

a Activated charcoal filter

b Filter

c Water separator

Fig. 5.1: Compressed air maintenance unit

If there is no compressed air plant available, the compressed air can be taken from an oil-free air

compressor with an output of 5– 8 bar as require.