8 .2 malfunctions and their remedy – BUCHI Inert Loop B-295 User Manual

Page 63

8 Troubleshooting

63

B-290 Operation Manual, Version I

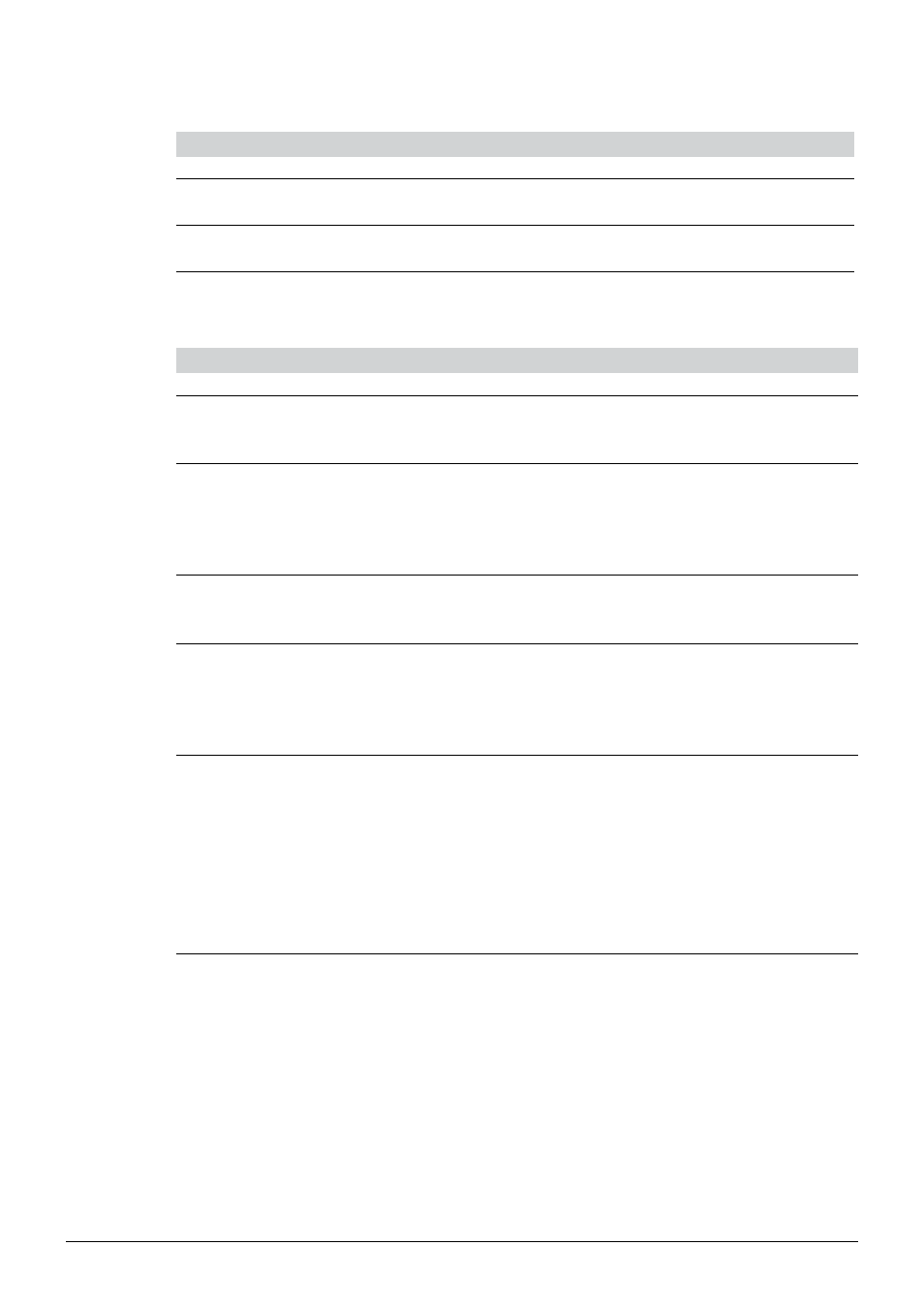

Table 8-1: Error messages and their remedy (cont.)

Code

Description

Possible cause

Corrective measure

203

Pressure alarm not given

during start-up

Pressure switch defective or conta-

minated

Contact the BUCHI customer

service

204

Humidity sensor above

threshold

Molecular sieve saturated with water

Exchange the molecular sieve bag

and regenerate the used one

8 .2

Malfunctions and their remedy

Table 8-2: Malfunctions and their remedy

Malfunction

Possible cause

Corrective measure

Equipment cannot be switched on No voltage

Fuse has blown

Insert mains plug/examine plug for

damage

Replace the fuse (3.15 A)

Peristaltic pump does not deliver

The rollers are not in contact with the

running surface

Elevate the running surface with the

lever

Adjust the lifting height of the running

surface with the hexagonal allen key

from beneath

Product is delivered after the

spray flow is switched on although

the pump is switched off

The pressure of the rollers on the

running surface is too weak

Adjust the lifting height of the running

surface with the hexagonal allen key

from beneath

Aspirator is noisy

The aspirator is dirty

The operating mode is set to “Blow”

Clean the aspirator

If no discharge filter is fitted, this

should be done to avoid further

contamination of the aspirator

Reset to “Suction” mode if possible

System does not heat up

Heating circuit not plugged in

Heating is not switched on

Nominal entry temperature is below

room temperature

Fuse has blown

Heater defective

Faulty tubing system

(Faulty flow direction or no flow in the

heating system)

Plug in heating circuit

Switch on heating circuit

Pre-select a new inlet temperature

Replace fuse (12.5 A)

Contact the BUCHI customer service

Check tubing system

Nozzle blocked up

Product is too concentrated

Encrustation on nozzle exit

Nozzle is not clean

Nozzle is defective (bent nozzle

needle)

Use a lower concentration in pump

Increase number of pulses for nozzle

cleaning

Cool nozzle with cooling water

Completely dismantle the nozzle

(nozzle cap, tip, cleaning needle)

and clean with water

Replace nozzle or defective element