Hollow shaft version, Requirements, English – Pilz PSEN enc s2 eCAM User Manual

Page 19: Assembly

Assembly

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: [email protected]

17

English

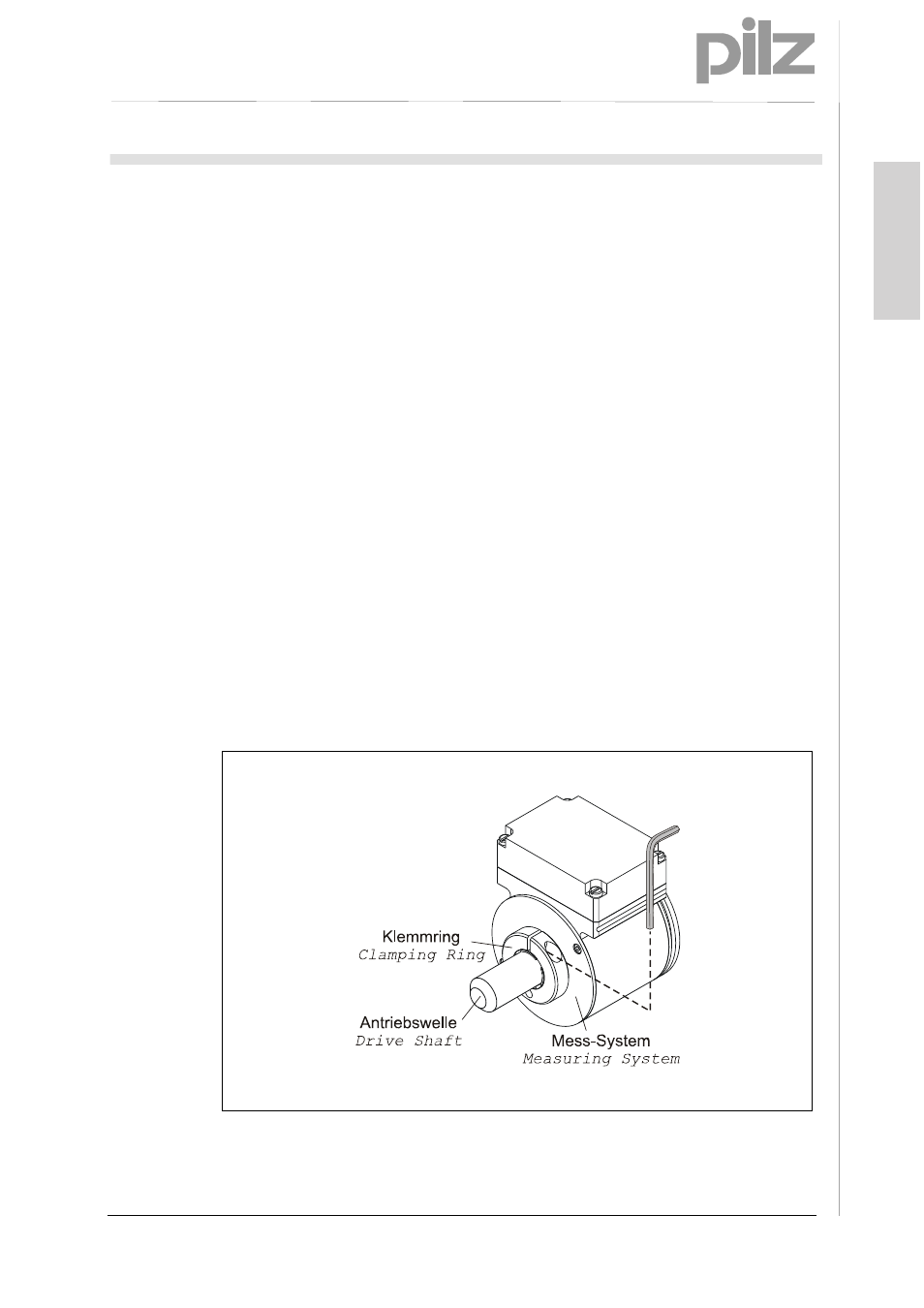

4.2 Hollow shaft version

4.2.1 Requirements

As the installation is application-dependent, the following instructions do not

claim to be exhaustive.

The measuring system should be installed on a greaseless shaft.

The clamping ring fixing should prevent axial slippage of the measuring

system on the drive shaft, see Figure 3.

Additional measures may be required to prevent axial slippage of the

measuring system.

The clamping of the measuring system must not have an axial load.

The screw on the clamping ring must be tightened to 3 Nm using a

torque wrench.

The screw on the clamping ring must be secured to stop it coming loose

unintentionally.

Positive locking using a parallel key/groove combination should prevent

radial slippage of the measuring system on the drive shaft; the

measuring system must be fixed to the drive side using a dowel pin, see

Fig. 4.

Fig. 3: Friction locking