Welch Allyn Connex Vital Signs Monitor PMP Tab Instructions - Quick Reference Guide User Manual

Page 10

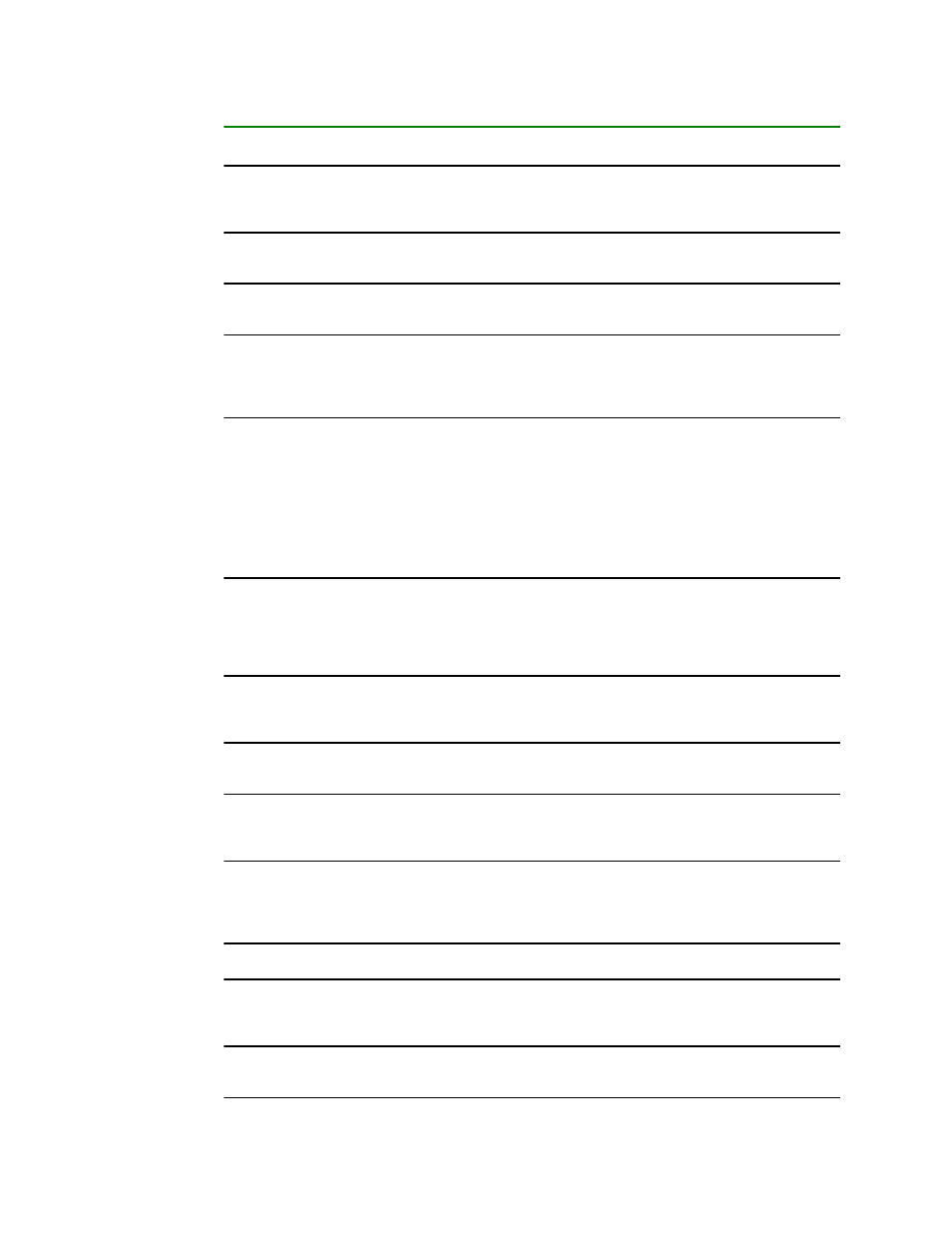

Error condition

Definition / Description

Required action

Powering down. Call for service.

This message could be caused by

various internal errors, power

manager, and battery faults.

The device will auto power off.

Battery is absent or faulty.

Battery is absent or faulty.

Plug the device into the outlet to

dismiss the message.

NIBP air leak; check cuff and

tubing connections.

An air leak has been detected.

Take corrective action; retake

measurement.

NIBP not functional. Call for

service.

This message could be caused by

various internal errors, a calibration

error, or ambient temperature or

module is out of range.

Retake measurement.

Unable to determine NIBP; check

cuff and tubing connections.

This message could be caused

because pressure exceeded the

maximum limit for the patient mode,

too much motion artifact to

calculate a reading, the system

dumped too soon, not enough data

could be obtained or the device

needed to re-inflate after it was

safe.

Limit patient movement; retake

measurement.

Unable to determine NIBP. Check

connections and tubing for kinks.

This message could be caused

because pressure exceeded the

maximum limit for the patient mode

or because pressure could not be

bled.

Retake measurement.

Incorrect NIBP cuff size. Check

patient type.

The patient is outside of the

module's capability to measure

NIBP.

Retake measurement.

Inflation too quick. Check NIBP cuff

and tubing connections.

Inflation was too quick; check for a

kinked hose.

Take corrective action; retake

measurement.

Unable to determine NIBP. Check

inflation settings.

Reading couldn’t be obtained

because a high enough inflation

couldn’t be reached.

Retake measurement.

SpO2 not functional. Call for

service.

This message could be caused by

various internal errors or a non-

functional SpO2 module, or SpO2

sensor may need to be replaced.

Attach SpO2 to monitor.

Sensor is not attached.

Check connections.

Replace SpO2 sensor.

SpO2 Sensor needs to be replaced.

This message may be caused by

BAD_PROBE error.

Set date and time.

Either date or time not set at all or

data has not been set.

Set date and time.

6 PMP alarm codes