9 corner correction, 1 general information, 2 checking corner load (dead load) – Rice Lake PR5220 Ethernet Transmitter User Manual

Page 91: 3 software corner correction, Corner correction, Pr 5220 instrument manual commissioning

PR 5220 Instrument Manual

Commissioning

Sartorius

EN-91

4.6.9

Corner Correction

4.6.9.1

General Information

An asymmetric scale construction doesn’t need a corner correction. But the corner correction may be necessary

at a symmetric scale construction.

4.6.9.2

Checking Corner Load (Dead Load)

After assignment and calibration, the load cell positions have been defined clearly.

4.6.9.3

Software Corner Correction

If the corners are loaded in succession, the same value should be displayed on the device at all times. An

excessive deviation almost always means that the scale is tilted or indicates load cell force shunts.

If the signal deviations cannot be resolved by carefully leveling the scale, the software must be calibrated.

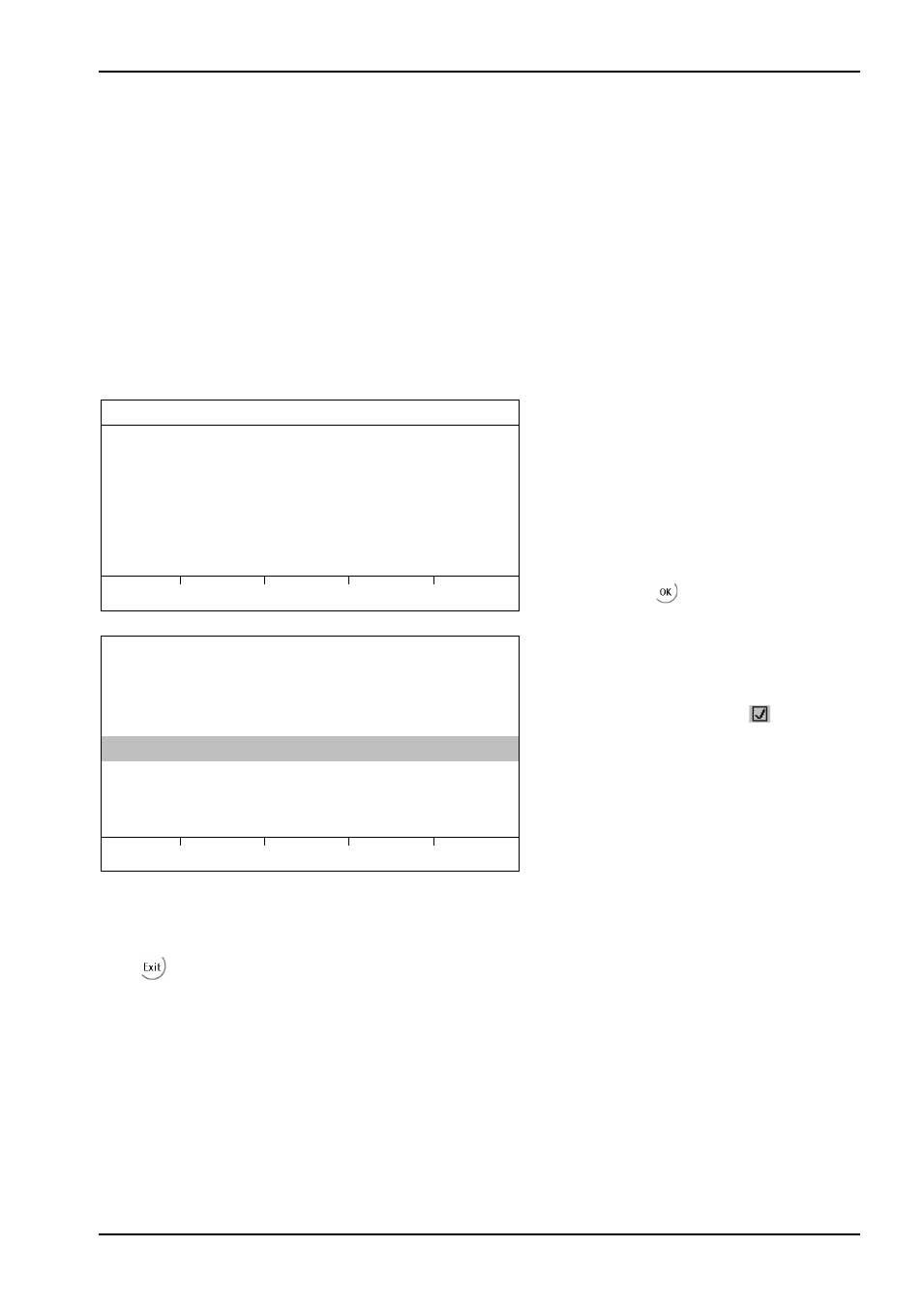

Weighingpoint/WP A/

Calibration

Number of vessel feet

4

Local gravity

9.81379 m/s

2

Max

10000 d

200.000 t

Scale interval

1 d

0.020 t

Dead load

7.511 t

CAL weight

10.000 t

Press [Modify] and

.

New

Modify

Param

Weighingpoint/WP A/Calibration/

Corner correction

Set the calibration weight on an area of

weighing construction.

The position (in this case, LC 4) is selected.

After confirmation (indicated by

), put the

weight onto the next position. The sequence is

unimportant. The cursor indicates the next load

cell/weight position.

LC 1

-0.008 t

LC 2

-0.008 t

LC 3

0.007 t

LC 4

0.008 t

Calc

When all load cells have been loaded once, you can press [Calc] to complete the corner correction.

The total weight remains unchanged. Only the effect of the individual load cells is corrected.

When corner correction is completed, the marking [ok] is shown.

Press

to return.