EFCO 8800 Series Assembly Instructions Vol.5 User Manual

Page 57

EFCO 2009

Page 57

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 5

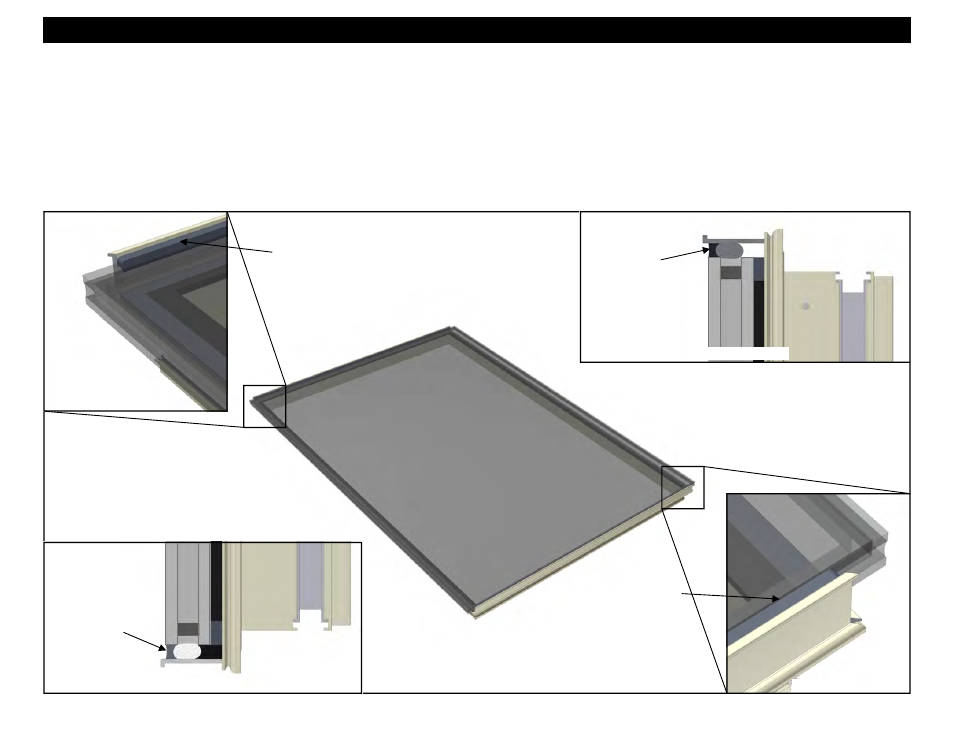

Figure 111

Section 26 - Assembly and Glazing - SSG Vent at Fixed Horizontal

18. Using an approved solvent or cleaner, clean the sealant contact surfaces of the glazing and head and sill fins of all oils and other contaminants.

19. If sealant primer is required, apply it per the primer/sealant manufacturer’s instructions.

20. Insert backer rod between the glazing and head and sill fins. See Figures 113 and 114.

21. Apply sealant into the void between the adapters and glazing. If the sealant is properly and carefully applied, masking tape is not necessary on the adjacent

surfaces.

22. Before the sealant begins to cure or skin over, tool the sealant into the joints smoothly, taking care to smooth and blend the sealant at each end of the head

and sill fin bars as shown below. Seen in section view, the sealant should have an hourglass shape and maintain a 2:1 width to depth ratio Remove any

excess sealant from the surrounding surfaces before the sealant begins to cure.

23. The glazed vent should not be moved before the structural sealant joints cure and per the sealant manufacturer’s recommendations.

Figure 113 - Sill

Figure 112

Figure 115

Apply backer

rod silicone

sealant into

the void and

tool smooth.

Apply backer

rod silicone

sealant into

the void and

tool smooth.

Tool sealant

smooth.

Tool sealant

smooth.

Figure 114 - Head