EFCO 8800 Series Assembly Instructions Vol.5 User Manual

Page 49

EFCO 2009

Page 49

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 5

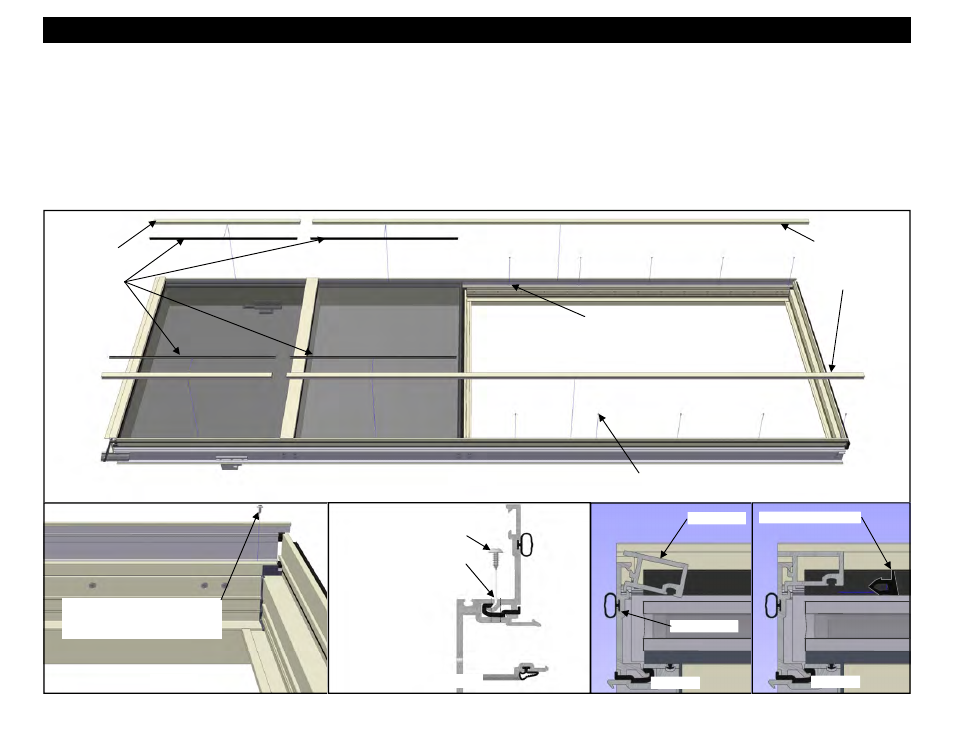

12. Drill tap sized holes (.113 diameter or #33 drill) in the face of the vertical assemblies, 1” from the sill end of the vent opening, and 18” on center to the top of

the vent opening. See figure 82 below. Drill the holes in the groove formed where the adapter meets the mullion. The holes should penetrate the adapter,

the isolator, and the first wall of the mullion where the isolator is seated. See Figure 82 below. Ensure the adapter is properly positioned and seated into the

isolator before drilling.

13. Apply STC6 fasteners in each hole to retain the adapters where they span the vent opening. See Figures 80 and 81.

14. Insert 17A3 cover into 17A2 captured glazing adapter at each unit jamb and rotate into place as shown in Figures 83 and 84.

15. Cut the WC22 gaskets approximately 2” longer than the D.L.O. dimension.

16. Drive in WC22 wedge gaskets as shown in Figure 84. The gaskets should be applied starting in the center of the D.L.O., and then working from the ends,

work the gaskets in place to the center of the lite.

Section 25 - Captured Vent Unit Glazing at Stack Sill : C. Adapter Installation

Figure 80

HEAD

SILL

Insert 17A3 covers

into 17A2 captured

glazing adapters

and drive in wedge

gaskets.

17A3 Covers

17A3 Cover

WC22 Wedge Gasket

17A2 Adapter

Figure 83

Figure 84

WC22 Wedge

Gaskets

Drill tap sized holes in the face of the

vertical assembly 1” from the sill end

of the vent opening, and 18” on

center to the top of the vent opening.

Apply STC6 fasteners in each hole to retain the

adapters where they span the vent opening.

Figure 82

Figure 81

Drill tap sized holes in the

groove formed where the

adapter meets the mullion.

Apply STC6 fasteners in each

hole to retain the adapters where

they span the vent opening.

STC6 18” o/c