Amico Falcon Combo Arm User Manual

Page 39

www.amico.com 39

Area

Maintenance

Period

(Month)

1

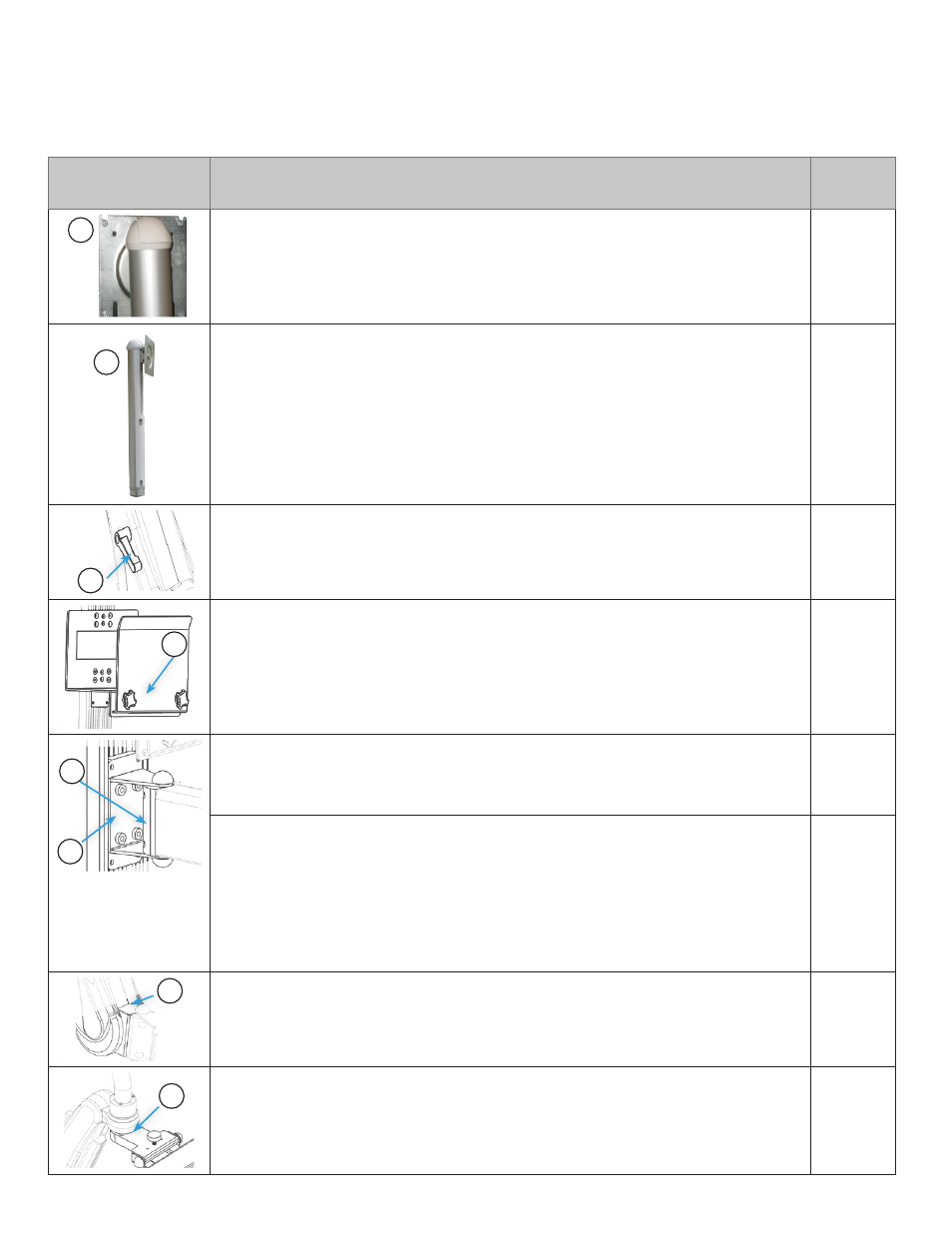

Area 1: VESA Adapter

A) Check if the adapter plate and the monitor are securely attached. VESA 75/100 (FIT) -

Ensure the four screws on the mounting plate(s) are fastened to the tightest possible

position.

B) Visually inspect for any signs of grinding and gapping.

4

1

2

Area 2: Swivel Post

A) Inspect the bolt, washers and contacting surfaces for grinding and wearing. Ensure the

bolt is tightened to the tightest position.

B) Check for any signs of gapping between the bushing and the head. Also ensure the head

of the AHM is level and is secure.

C) Inspect the bolt, washers and contacting surfaces for grinding and wearing.

D) Inspect rivet.

1

4

4

4

3

Area 3: Height Adjustment Lever

A) Ensure the adjustment lever is tight and secure. Also inspect visually for any signs of

impact or wear on the outside surface of the AHM arm.

1

4

Area 4: CPU Mount

A) Ensure the two set screws on the channel and two thumb screws are fastened to the

tightest possible Position.

1

6

5

Area 5: Swivel Block At Adapter

A) Ensure all the screws are fastened to the tightest possible position. Inspect for any signs

of grinding, bending and gapping and ensure the AHM arm is tightly attached to the

swivel block.

4

Area 6: Rail Bracket (MON Adapter shown)

B) Inspect visually for any gapping between the bracket and the adapter. Ensure the bracket

is tightly attached to the adapter.

• MRS - Ensure the screws are fastened to the tightest possible position (shown in

image)

• VRS - Ensure the screw knobs are fastened to the tightest possible position and nuts

on the opposite side are secure. (See Page 9)

4

7

Area 7: AHM Internals

A) Visually inspect for any grinding or gapping of the contacting surfaces. Check for any fluid

leakage from the gas spring.

1

8

Area 8: Keyboard Swivel Block

A) Visually inspect for any gapping between the keyboard swivel block and the AHM head.

Also check for any signs of grinding on the surfaces contacting the screw and the nut.

1

SECTION 5: Troubleshooting, Maintenance,

Product Classification