Great Plains YP825AR Operator Manual User Manual

Page 97

Great Plains Manufacturing, Inc.

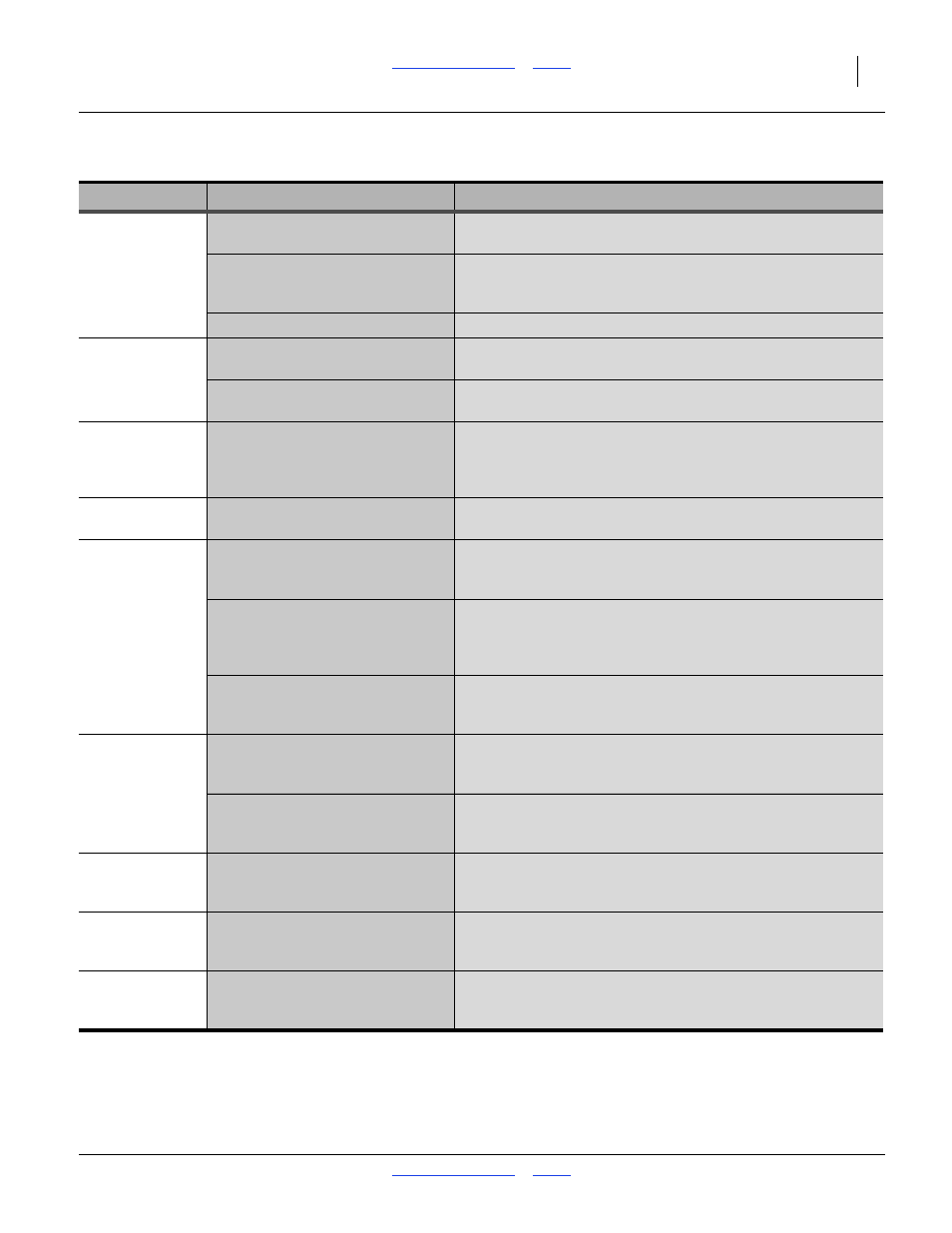

Troubleshooting

93

2014-06-17

401-923M

Low Pressure, at

Desired Rate

Orifice size too large

Choose alternate orifice plate size based on charts in Seed

and Fertilizer Rate manual (401-923B).

Orifices correct plate call size, but

their holes are enlarged from

extended use

Obtain new plates in the desired size. Discard worn plates.

Rate may actually be low

Check fertilizer transmission Driving/Driven sprockets.

Uneven Flow, at

Desired Rate

One or more orifice plates plugged Clean and re-installed orifice plates. Check that materials are

not too viscous or granular for the orifice size.

Plate sizes vary between rows

Check that all nozzles have the same size plates (with the

possible exception of outside rows serving zone coulters).

Pressure

Unstable

Strainer clogged

Dumping at

Normal Pressure

Relief valve setting too low

Review relief valve setting per Seed and Fertilizer Rate

manual (401-923B).

High Pressure, at

Desired Rate

Orifice size too small

Review orifice sizing. If at recommended size, try the next

large size. Charts are based on typical density/viscosity

materials.

Plugged nozzles

Inspect low-flow rows, or several nozzles. Clean plates.

Consider smaller strainer screen size and/or large orifice

plate size. Sedimentation, coagulation, particulates, foreign

matter can also cause unusually high pressure.

Orifice plates inverted

Orient plates with legends facing outlet. Orifice port holes are

not symmetrical, and at smaller sizes this can cause slightly

higher back-pressure with denser materials.

Very High

Flow

Fertilizer transmission in High

Range when Low Range was

intended.

Swap sprockets at transmission. See Seed and Fertilizer

Rate manual (401-923B).

Various possible pump issues

Pump Leaks

Various possible pump issues

Pump Oil

Consumption

Pump seals or O-ring

Noisy Pump

Crankcases components worn

Liquid Fertilizer Troubleshooting

Problem

Cause

Solution