Loading liquid fertilizer (option), System inspection, Tank loading – Great Plains YP825AR Operator Manual User Manual

Page 43

Great Plains Manufacturing, Inc.

Operating Instructions

39

2014-06-17

401-923M

Loading Liquid Fertilizer (Option)

If liquid fertilizer will not be applied, lock-up the fertilizer

ground drive (page 21), or disengage the chain on the

pump drive.

System Inspection

1.

Wear protective equipment suitable for the material

presently in or previously dispensed from the tank(s).

2.

Remove the lid on each tank and inspect for:

- residual fertilizer incompatible with next use

- contaminants

- debris that might clog filters

- trapped animals lost tools, etc.

3.

If it is necessary to flush a tank, or remove debris too

large to flush, see “Tank Clean-Out” on page 98.

4.

Re-secure each lid.

5.

At first use each season, and after extended use,

check the strainer mounted under the pump. Perform

any cleaning before loading fertilizer.

6.

The standard screen size is 80 (Blue). Some orifice

selections (step 9) require changing the strainer.

Tank Loading

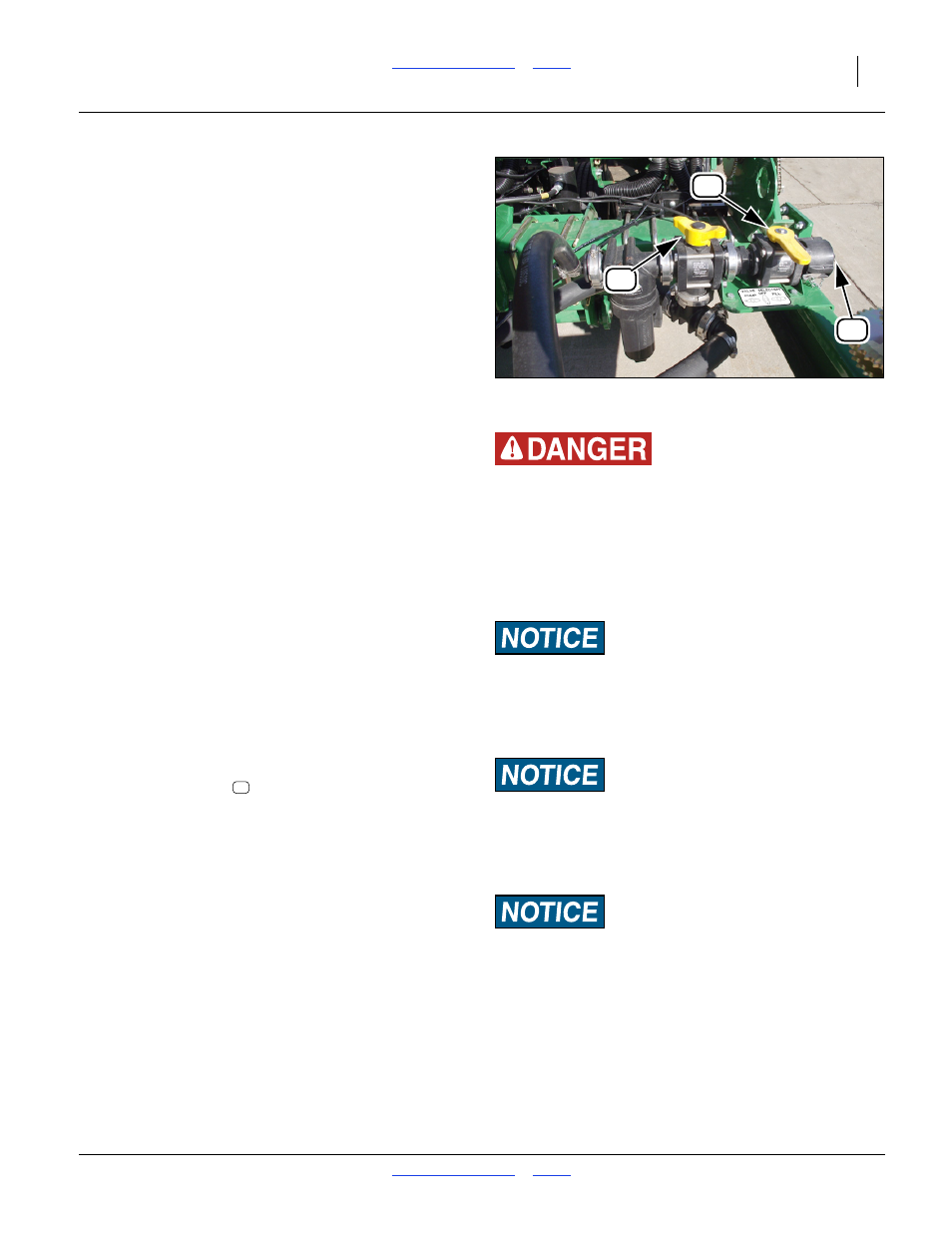

Refer to Figure 39, and

Figure 129 on page 135

Review the information below before commencing steps.

• Load chemicals immediately prior to use. Material

loaded too early may sediment or stratify, resulting in

uneven application or system plugging.

• Load on level ground. Fill is uneven across a slope on

a dual-tank system. Unless valves are set to prevent it,

material can flow from one tank to another.

• The tank is designed to be loaded using the 2 inch

CAM quick-fill inlet (

), located at the left front of the

implement. If for any reason you cannot use that inlet,

you can also load material via a ladder and tank top

hatch. The lid is threaded and unscrews.

• Determine how to monitor tank fill level. If the day is

bright, or loading at night with a bright light available, it

is possible to see the fluid level through the

semi-translucent tank walls. Otherwise, it is necessary

to have an observer monitor through the tank hatch.

• Be familiar with the location of plumbing valves.

Common task require setting as many as five planter

valves. See page 135.

7.

Consult the Seed and Fertilizer Rate manual

(401-923B) for rate setting details.

8.

Set the Fertilizer drive sprockets and piston pump

rate adjuster per the Rate charts.

9.

Install the recommended size orifice plate at each

active drop line (Seed Rate manual).

11

13

12

Agricultural Chemical Hazard:

Avoid contact with skin or eyes. Wear proper protective

equipment as required by chemical manufacturer. Avoid

prolonged breathing of chemical fumes. Wear respirator as

required by chemical manufacturer. Some chemicals will cause

serious burns, lung damage, and death. Seek medical

assistance immediately if an accident occurs. Know what to do

in case of accident.

Equipment Damage Risk:

Do not run the pump when dry. Remove the final pump drive

chain if not applying fertilizer. Air rapidly corrodes the pump.

When not pumping, fill the pump with clean water or RV

antifreeze.

Equipment Damage and Plugging Risks:

Use only materials compatible with polyethylene and

polypropylene. Use only pre-mixed liquid fertilizer. The system

is not designed for dry fertilizer mixes. Granular fertilizer may

damage the pump and plug orifices.

Equipment Damage Risk:

Do not leave fertilizer standing. Load late. Pump it all. Clean

out the system. Fertilizer is usually extremely caustic, and can

damage the piston pump if left standing. Also protect the pump

from air. See “Liquid Fertilizer Clean-Out” on page 98.

Note: Is it not possible to use the planter pump to load

material, as it only pumps when the planter is in

motion and is only plumbed to pump to the boom.

If the fertilizer source has no pump, it needs to be

elevated above the tank for gravity fill.

Figure 39

Quick-Fill Inlet

31996

11