Magnehelic® gauge troubleshooting, Magnehelic – Great Plains YP825AR Operator Manual User Manual

Page 89

Great Plains Manufacturing, Inc.

Troubleshooting

85

2014-06-17

401-923M

Magnehelic

®

Gauge Troubleshooting

If the Magnehelic

®

gauge does not read zero with the fan

off, inspect the gauge, and re-zero as needed.

Check for chamber and breather line problems before

re-zero. Re-zero cannot accurately compensate for leaks

and blockages.

Re-zero the Magnehelic

®

gauge on level ground with the

fan off, and if possible, under no-wind conditions. Turn

the set screw

on the meter face until it reads zero from

the tractor driver’s viewing position.

Problem

Cause

Solution

Non-zero

with fan off

Zero drift

Re-zero per

instructions below

Gauge

reading

lower than

sensor

Relief port plug

missing/damaged

Replace plug

Breather line

blocked or kinked

Clear breather line

Leak in sensing

line

Check line to

chamber

Gauge damaged

Check for loose

cover, damaged

O-ring

1

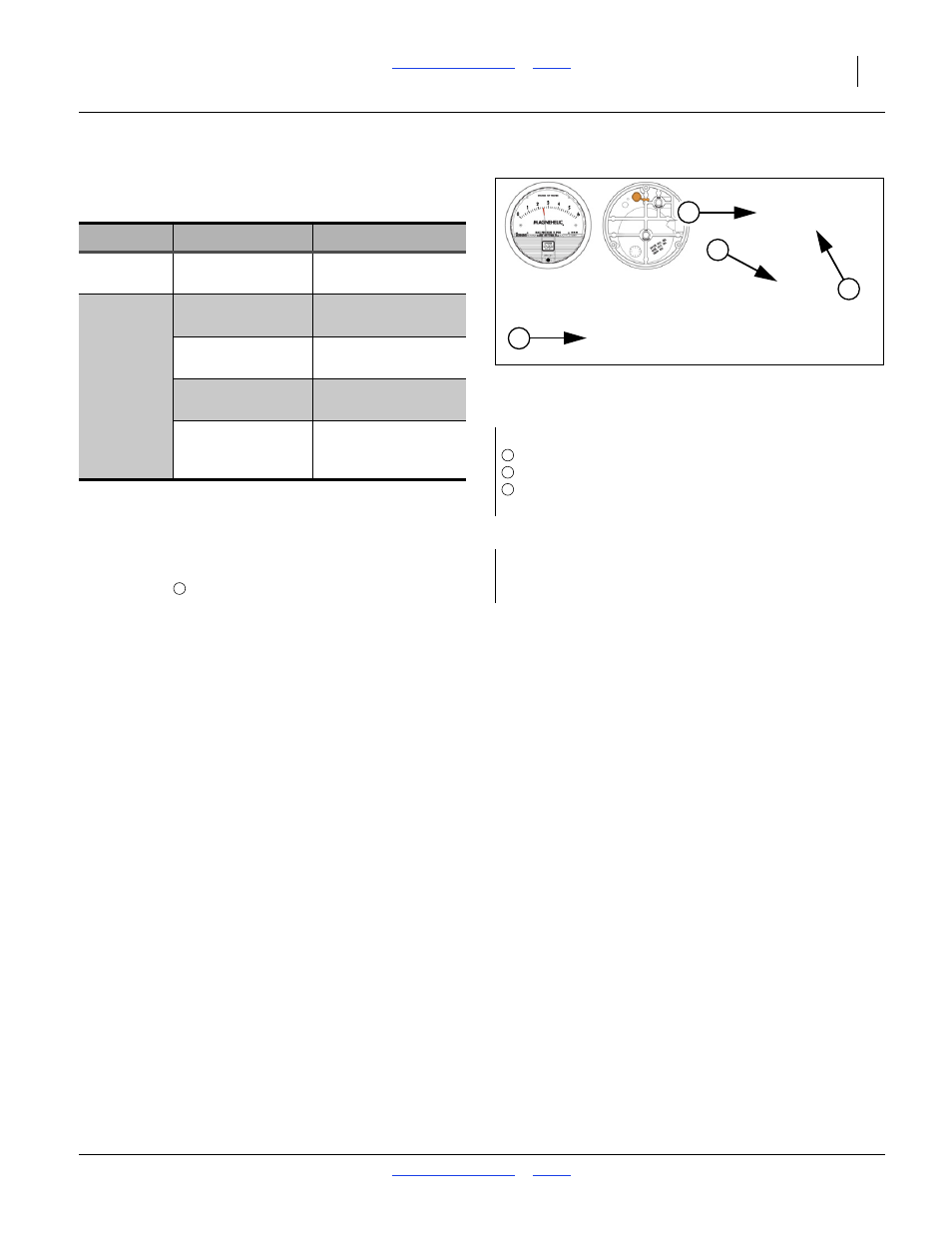

Figure 108

Magnehelic

®

Gauge

29842

Port ID for Troubleshooting:

Over-pressure relief port (with plug in place)

Low-pressure port (breather/atmospheric pressure)

High-pressure port (from manifold chamber)

Alternate high/low ports are plugged.

Winter testing/maintenance advisory:

Gauge readings may be inaccurate or sluggish below

20

°F

2

3

4

3

2

4

1