Loading dry fertilizer (twin row), Suitable materials, System inspection – Great Plains YP825AR Operator Manual User Manual

Page 46: Hopper lid operation

42

YP825AR

Great Plains Manufacturing, Inc.

401-923M

2014-06-17

Loading Dry Fertilizer (Twin Row)

Loading liquid fertilizer is found on page 39.

If fertilizer will not be applied, uncouple the fertilizer

meter shaft at the left end of the left hopper. Pin the

coupler clear of the shaft joint.

Loading fertilizer prior to transport is not recommended.

Although the meters are not turning during transport, it is

possible for some material to spill through the meters,

particularly on rough roads.

Suitable Materials

Use only dry granular fertilizer. Granules must flow freely,

and must have a maximum diameter smaller than 7 mm

(to avoid bridging clogs in the applicator tube outlets).

Agricultural Chemical Hazard:

Wear protective equipment suitable for the material to be used,

and the material previously dispensed from the hoppers. Avoid

contact with skin or eyes. Avoid breathing dust.

System Inspection

Verify that both rear cradle pins are installed on all

hoppers. See Figure 114 on page 99.

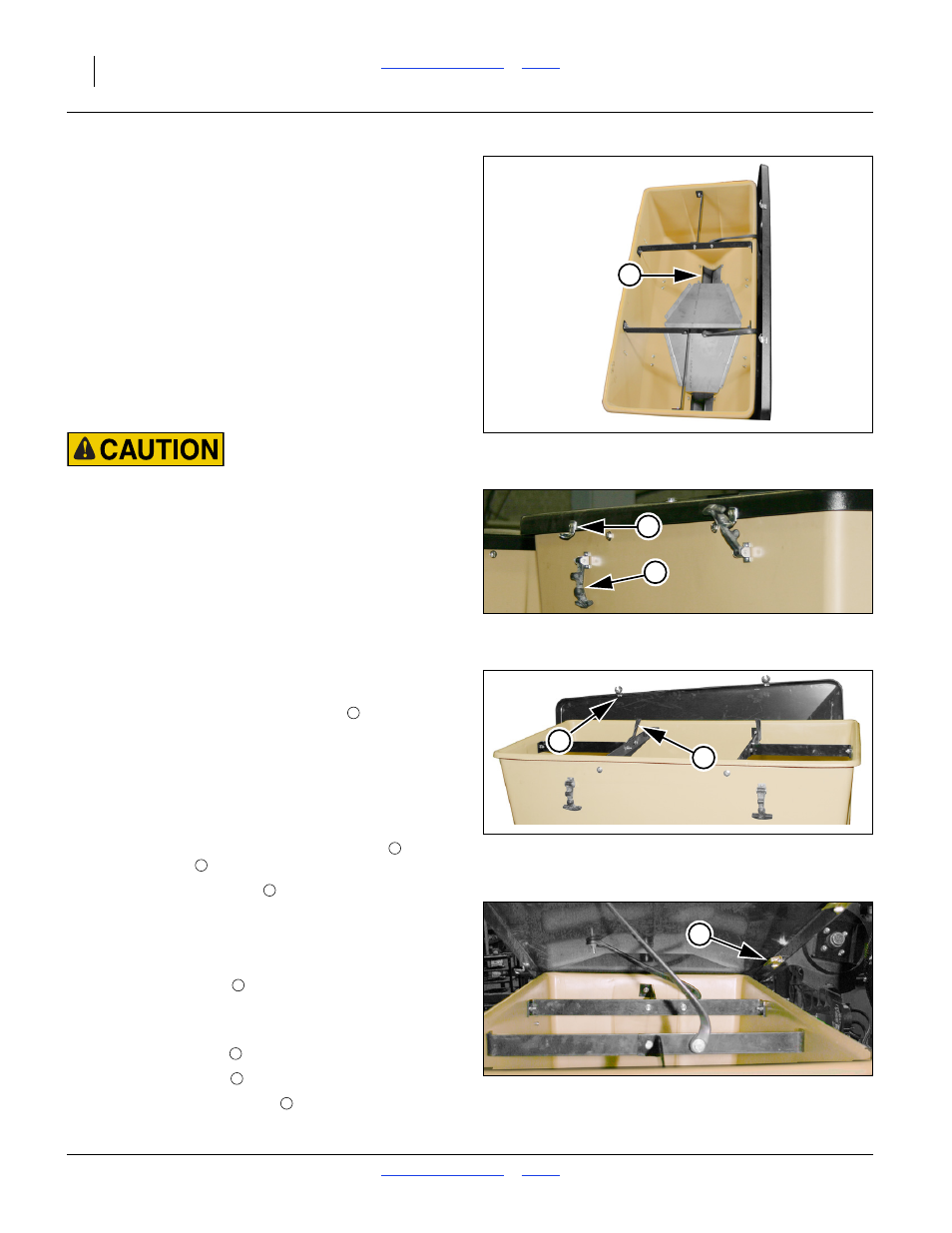

Refer to Figure 42

Remove the lid on each hopper and inspect for:

• residual fertilizer incompatible with next use

• contaminants

• debris that might clog the meter inlets

• trapped animals lost tools, etc.

If it is necessary to clean a hopper, see “Dry Fertilizer

Clean-Out” on page 99.

Hopper Lid Operation

Refer to Figure 43 and Figure 45

To unlock the hopper lid, lift the rubber latches

out of

the metal keepers

.

Note: The keeper hardware

tends to snag under the

hopper lip. Pull the lid edge forward and lift.

Refer to Figure 44

To open the lid, lift the front edge up and slide the lid

back into a vertical position behind the hopper. The lid is

held by retaining straps

.

Refer to Figure 43, 44 and 45

When closing the lid make sure that:

• the rear catch plates

are under the hopper rear lip,

• the keeper hardware

is under the front lip, and

• the ball of each rubber latch

is seated in the keeper.

(If only the handle “T” is seated, the lid is not secure.)

Figure 42

Empty 2- Outlet Hopper

31866

1

Figure 43

Hopper Latch Open and Closed

31866

2

3

Figure 44

Hopper Lid Open

31865

4

5

1

2

3

Figure 45

Hopper Lid Rear Catch Plate

31864

6

4

5

5

4

2