Dry fertilizer adjustments (option), Single-row augers – Great Plains YP825AR Operator Manual User Manual

Page 64

60

YP825AR

Great Plains Manufacturing, Inc.

401-923M

2014-06-17

Dry Fertilizer Adjustments (Option)

Refer to Figure 60

Application Rate Risk:

Make field checks to assure you are applying fertilizer at the

desired rate. Fertilizer application rates can vary from the

weights in the charts.

Use the following instructions to check the exact number

of kilograms your fertilizer attachment delivers on a

70 cm or 75 cm row spacing.

1.

Adjust for your fertilizer density (see Seed Rate

Manual 401-923B).

2.

Consult the Fertilizer Rate charts (see Seed Rate

Manual 401-923B).

3.

Install the Driving

and Driven

sprockets called

out in the chart.

4.

Remove a hose from one of the fertilizer hoppers

and attach a container under the opening.

5.

Engage the fertilizer attachment and drive forward:

14.29 m (49 feet) for 70 cm row spacing

13.33 m (43 feet 8 inches) for 75 cm row spacing.

6.

Weigh the amount of fertilizer caught in the container

and multiply that amount by 100. The result is the

kilograms of fertilizer delivered per hectare.

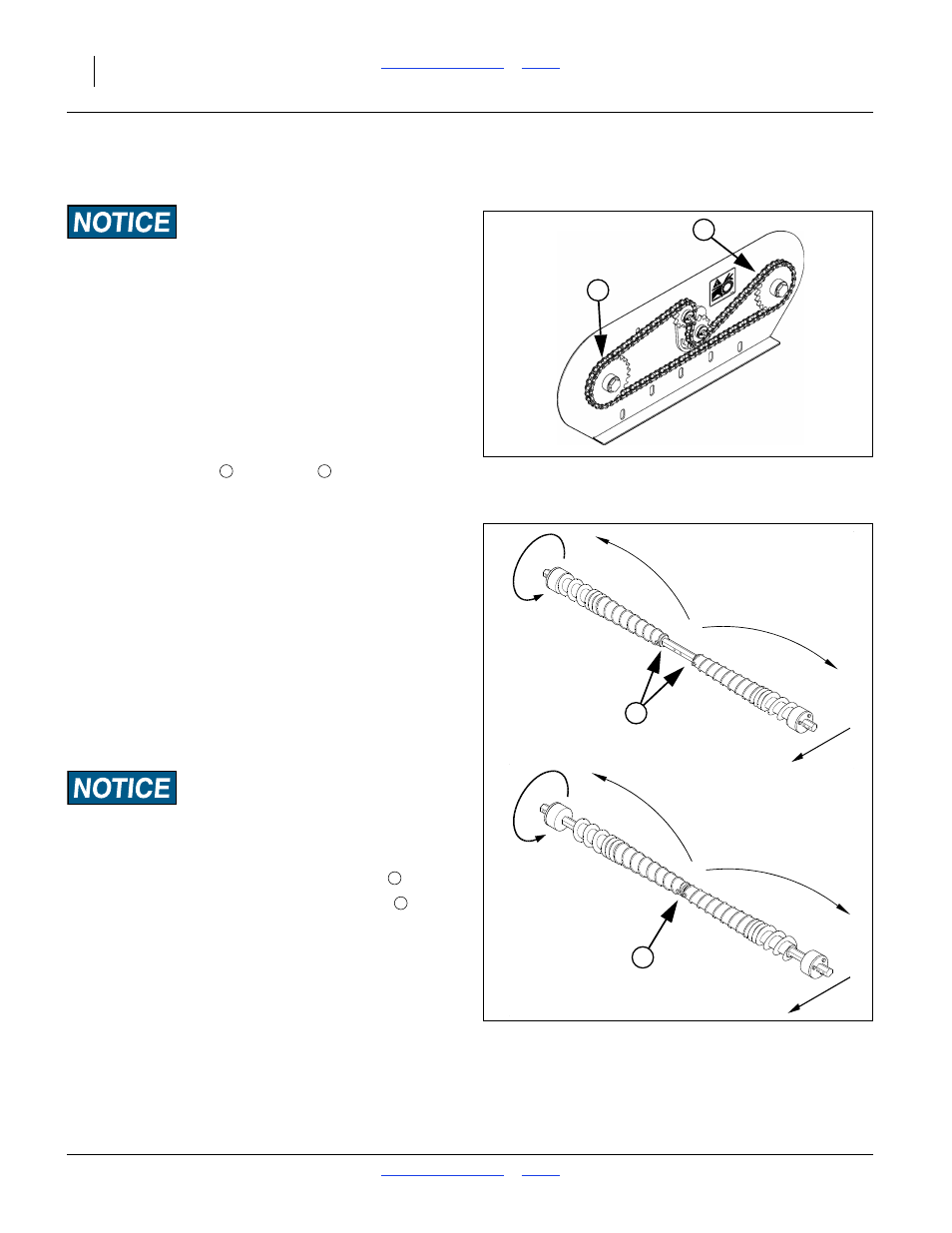

Single-Row Augers

Dry fertilizer hoppers with a single outlet at each end

have adjustable augers for delivering material to the

outlets. Twin-row planters do not have this feature.

Refer to Figure 61

Material and Time Loss Risk:

Before applying fertilizer make sure that augers are rotating

correctly and are positioned for your desired rate setting.

For low fertilizer rates, set augers as shown at

.

For high fertilizer rates, set augers as shown at

.

Figure 60

Fertilizer Transmission

25469

1

2

DRIVING

DRIVEN

1

2

Figure 61

Fertilizer Auger Adjustment

15699

15696

4

3

LOW RATE

HIGH RATE

3

4