Appendix c - initial setup, Post-delivery checklist, Initial marker setup (option) – Great Plains YP825AR Operator Manual User Manual

Page 154: Marker speed adjustment

401-923M

2014-06-17

150

YP825AR

Great Plains Manufacturing, Inc.

Appendix C - Initial Setup

This Appendix covers setup tasks performed only once,

or at infrequent intervals. Routine setup tasks are

covered in “Preparation and Setup” on page 13.

Perform Appendix B tasks first. Some of these items may

already have been done by your Great Plains dealer:

a.

Frame-mounted row options

(see manual supplied with accessory)

b.

Marker setup (Option, page 150)

c.

High rate dribblers (Option, page 153)

d.

e.

Fertilizer drop lines (Option, page 155)

Initial Marker Setup (Option)

Marker Speed Adjustment

Overhead Sharp Object and Crushing Hazards:

Never allow anyone near the planter when folding or

unfolding the markers. You may be injured if hit by a folding or

unfolding marker. Markers may fall quickly and unexpectedly

if the hydraulics fail. Marker discs may be sharp.

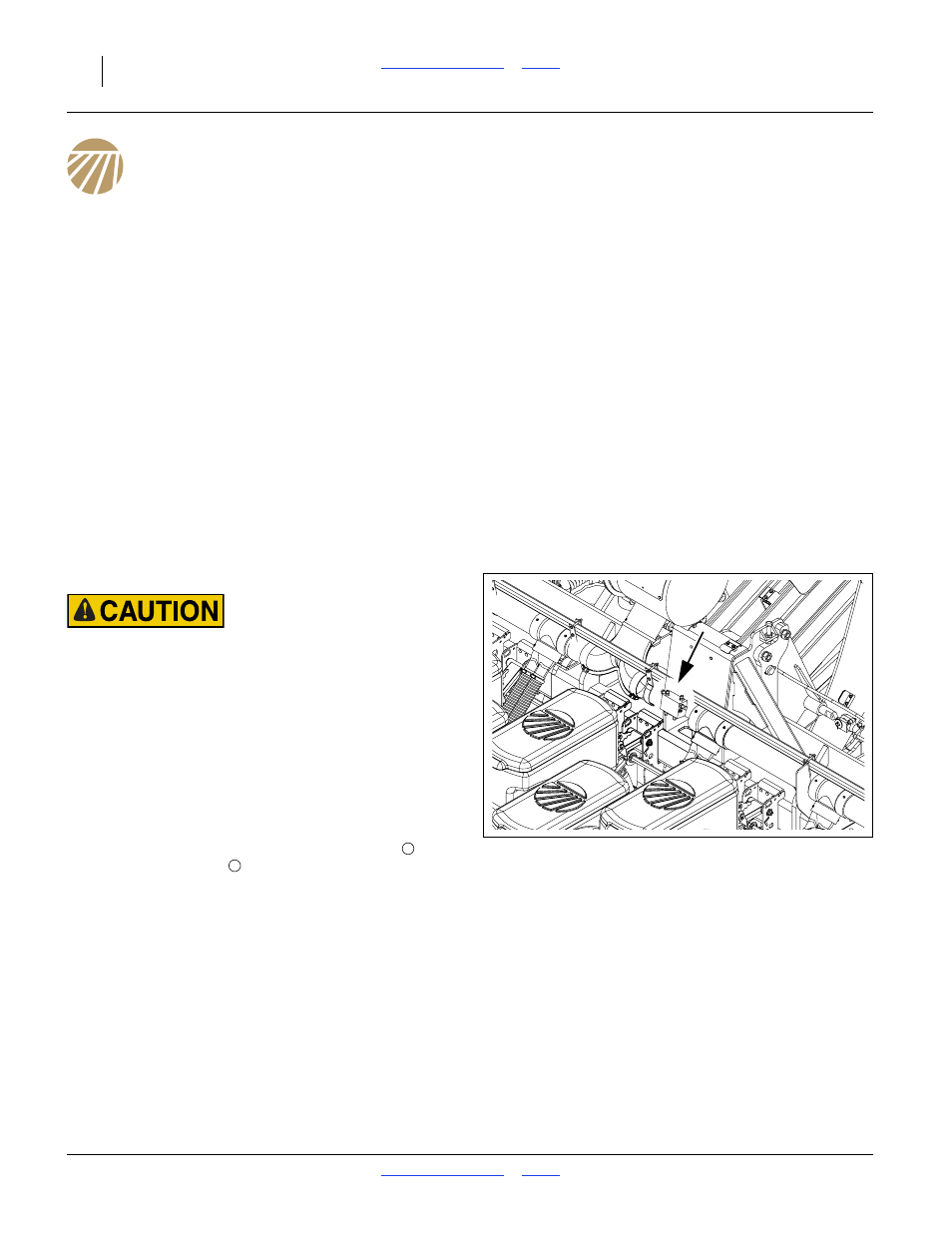

Refer to Figure 130 and Figure 131

Adjust folding speed for dual markers with hex

adjustment screws on the sequence valve body. The

valve sequence body is rear center on the lift structure,

below the fan. Loosen jam nuts before making

adjustments.

There is one adjustment screw for raising speed

and

one for lowering speed

. You can identify adjustment

screws by markings stamped in valve body.

Post-Delivery Checklist

1.

Read and understand “Important Safety

Information” on page 1.

2.

Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3.

Check that all grease fittings are in place and

lubricated. See “Lubrication and Scheduled

Maintenance” on page 108.

4.

Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 6.

5.

Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 134.

Figure 130

Marker Sequence Valve Location

34805

1

2