Air system clean-out – Great Plains YP1625A Operator Manual User Manual

Page 95

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

91

2013-08-13

401-625M

Air System Clean-Out

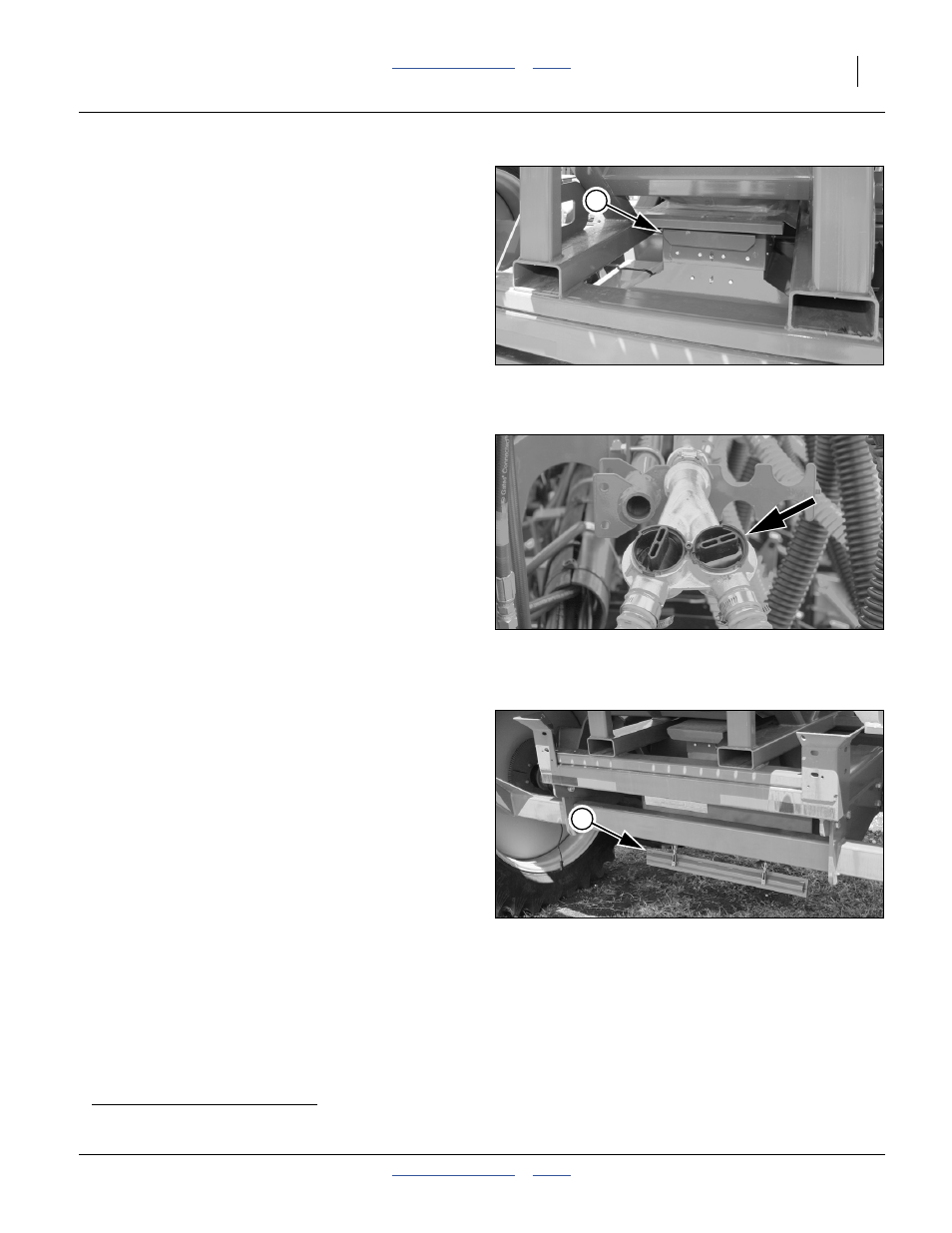

Refer to Figure 112

1.

Shut off slide gate door at bottom of seed box or bulk

hopper.

2.

Place a pan or tarp under the airbox manifold to

catch seed.

Refer to Figure 113

3.

If the planter has Y-tubes, shut off the gates at all of

the Y-tubes.

Refer to Figure 114

4.

Open airbox clean-out door to empty seed from the

manifold.

Note: If needed, additional access doors are provided.

5.

Shut the clean-out door under manifold.

6.

Turn on the air fan and let it run. Use the

“SPLIT AIR -” softkey

a

to reduce the regulated air

pressure to a low value, 1 inch H

2

O or less - this

diverts most of the air to the bulk seed delivery

system.

If most of the meters are shut off, reduce fan speed

as necessary to obtain a low meter pressurization.

7.

Start at one end of planter and perform a meter

clean-out (page 92).

8.

Open the Y-tube gate feeding that meter. Let the air

blow seed out of the meter. Use the meter shutter to

start and stop seed flow if using a small container.

9.

Close the Y-tube gate and shutter for that meter.

10. Repeat procedure on the next meter in line. Continue

with this procedure until you have reached the

opposite end of the planter.

11. Final Check:

During air system clean-out, it is common for a few

seeds to dislodge and make their way to meters

already cleaned. To avoid seed size causing

problems for the next disk to be used, and to avoid

crop mixing, make a pass along all the rows, opening

and closing shutters, removing any stray seed.

a. The “FILL METER” function can divert all the air to seed delivery, but only does so for a short period of time (~90 seconds).

Figure 112

Slide Gate Closed

29495

3

Figure 113

Y-Tube Shut-Off

29758

Figure 114

Airbox Clean-Out Door Open

29494

2