Install marker extension tube, Check disk orientation, Insert and secure tube – Great Plains YP1625A Operator Manual User Manual

Page 148

144

YP1125A & YP1625A

Great Plains Manufacturing, Inc.

401-625M

2013-08-13

Install Marker Extension Tube

Check Disk Orientation

Refer to Figure 150 (C: to Center; W: to Wing)

18. Select one:

113-794D MARKER EXTENSION TUBE

These tube assemblies

are identical for LH and

RH use. The disk and spindle

are pre-assembled.

Prior to installing the marker extension tube, inspect

the disk assembly. The bolts securing the spindle

weldment to the tube are to be vertical after

installation, and the spindle

is to be to the front.

This is merely the factory default orientation. The

operator may change it as needed.

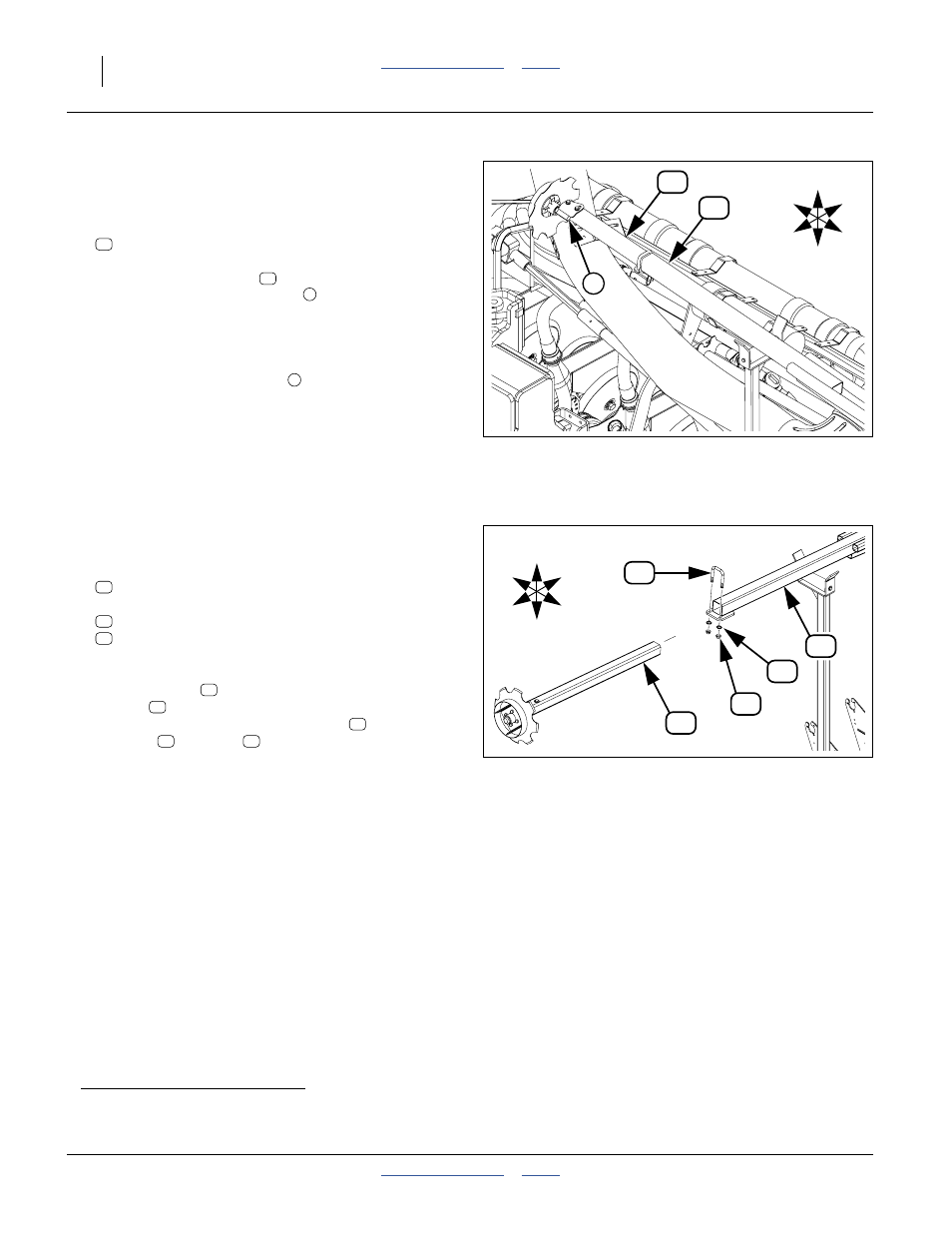

Insert and Secure Tube

For each wing:

Refer to Figure 151 (C: to Center; W: to Wing)

19. Select one:

806-110C U-BOLT 5/8-11 X 3 1/32 X 4 1/2

and two sets:

804-022C WASHER LOCK SPRING 5/8 PLT

803-021C NUT HEX 5/8-11 PLT

Minding the spindle orientation, insert the marker

extension tube

into the marker arm second

section

to a depth of about

a

18 inches (45 cm).

Secure the extension with the U-bolt

, lock

washers

and nuts

.

Figure 150

LH Marker Spindle Orientation

34386

11

5

U

D

F

B

W

C

14

14

14

a. Exact extension value depends on row spacing, row utilization and desired disk angle. Setting this requires full monitor and hydraulic

connections, then unfolding the planter and markers in field conditions. See “Marker Setup” on page 150.

Figure 151

LH Marker Extension Tube

24408

U

D

C

W

F

B

41

14

38

32

11

41

38

32

14

11

41

38

32