Field setup checklist – Great Plains YP1625A Operator Manual User Manual

Page 40

36

YP1125A & YP1625A

Great Plains Manufacturing, Inc.

401-625M

2013-08-13

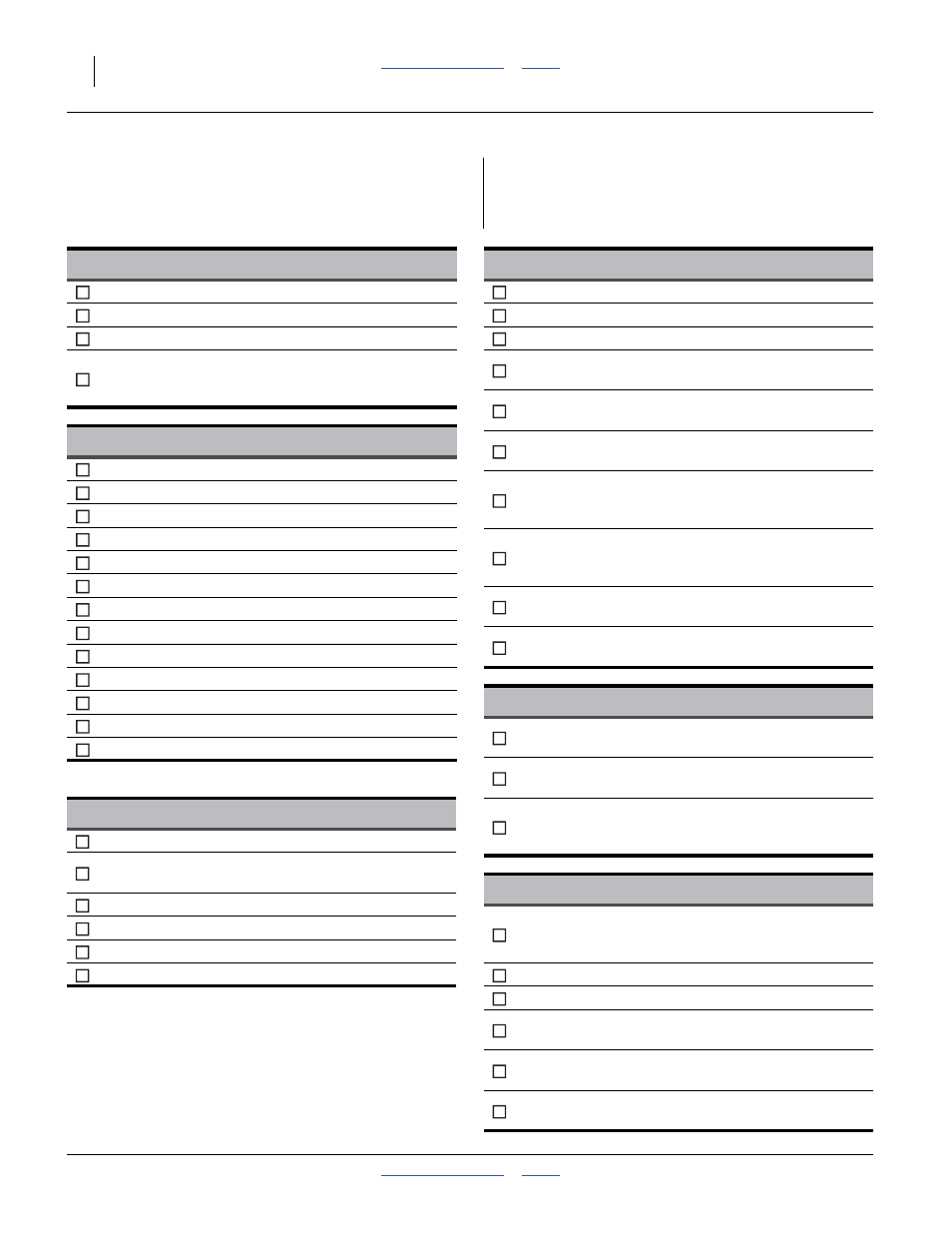

Field Setup Checklist

Use the following checklist as a guide to ensure the

planter is properly setup before using.

To complete checklists, you may need to refer to the:

SRM: Seed Rate Manual (SRM),

PDC: DICKEY-john

®

Planter/Drill Control manuals, or

QSG: DICKEY-john

®

Quick Start Guide

ELECTRICAL

Page

All connections made

17

Check all lights

Power up monitor. Watch for diagnostics.

PDC

Verify Material, Rate and “SPLIT AIR”

Channel setup. Verify Channel setup for

hydraulic drive (Option).

QSG

PDC

HYDRAULIC

Page

Tractor reservoir full

Marker/Aux valve to Marker (Option)

All hydraulic circuits connected

15

Fan direction and rpm

42

Hydraulic drive connection

a

(Option)

a. Perform a “FILL DISK” operation via the seed monitor.

Raise tongue. Lift planter

Begin unfold

Re-phase fold system

Lower tongue

Unfold wings. Check for tongue lock.

Re-phase lift cylinders

Check marker operation

Inspect for hydraulic leaks

MECHANICAL

Page

Tongue height preset on 3-point

17

Set tractor 3-point hitch to “depth control”

operation (and not load control)

45

Side to side levelness at gauge wheels

Toe-in of wing frames at pull-bars

Tongue hook latch operation

22

Marker extension and disk angle set

150

AIR SYSTEM

Page

Manifold to PROBOX

®

or poly hopper seal.

30

Y-splitters turned off for unused rows.

Blank disks installed at unused rows.

72

Air leaks (small leaks from PROBOX

®

are

normal).

84

Hose routings, no sags and no pinched

hoses. (Check folded and field positions.)

Hoses fully connected to meters and

locked.

Start fan. Turn on seed monitor active air

control. Watch for split air vane movement

or air pressure changes.

PDC

Activate the “FILL METER” function of the

monitor. Watch for air vane movement, or

watch meter pressurization go to zero.

PDC

On a new planter, pre-lubricate the air

system with Ezee Glide Plus.

30

Set the meter pressurization target to the

recommended value for the crop.

PDC

ROW CLEANERS

Page

Check for correct installation of row

cleaners on all rows if equipped.

Check that row cleaners do not catch on

hydraulic hoses.

Carefully watch when folding and unfolding

planter the first time to ensure clearance of

row cleaners.

FERTILIZER

Page

Set rate drive sprockets for correct rate.

(Note fertilizer rate is population

dependent.)

SRM

Check for correct orifice plates.

SRM

Check unused rows are correctly closed off. SRM

Fill system 1/2 full with water and check for

leaks (run pump if possible).

SRM

Disconnect drive chain if fertilizer is not

used.

SRM

Check all row unit lines are connected and

discharge nozzles or tubes are clear.

SRM