Great Plains YP1625A Operator Manual User Manual

Page 87

Great Plains Manufacturing, Inc.

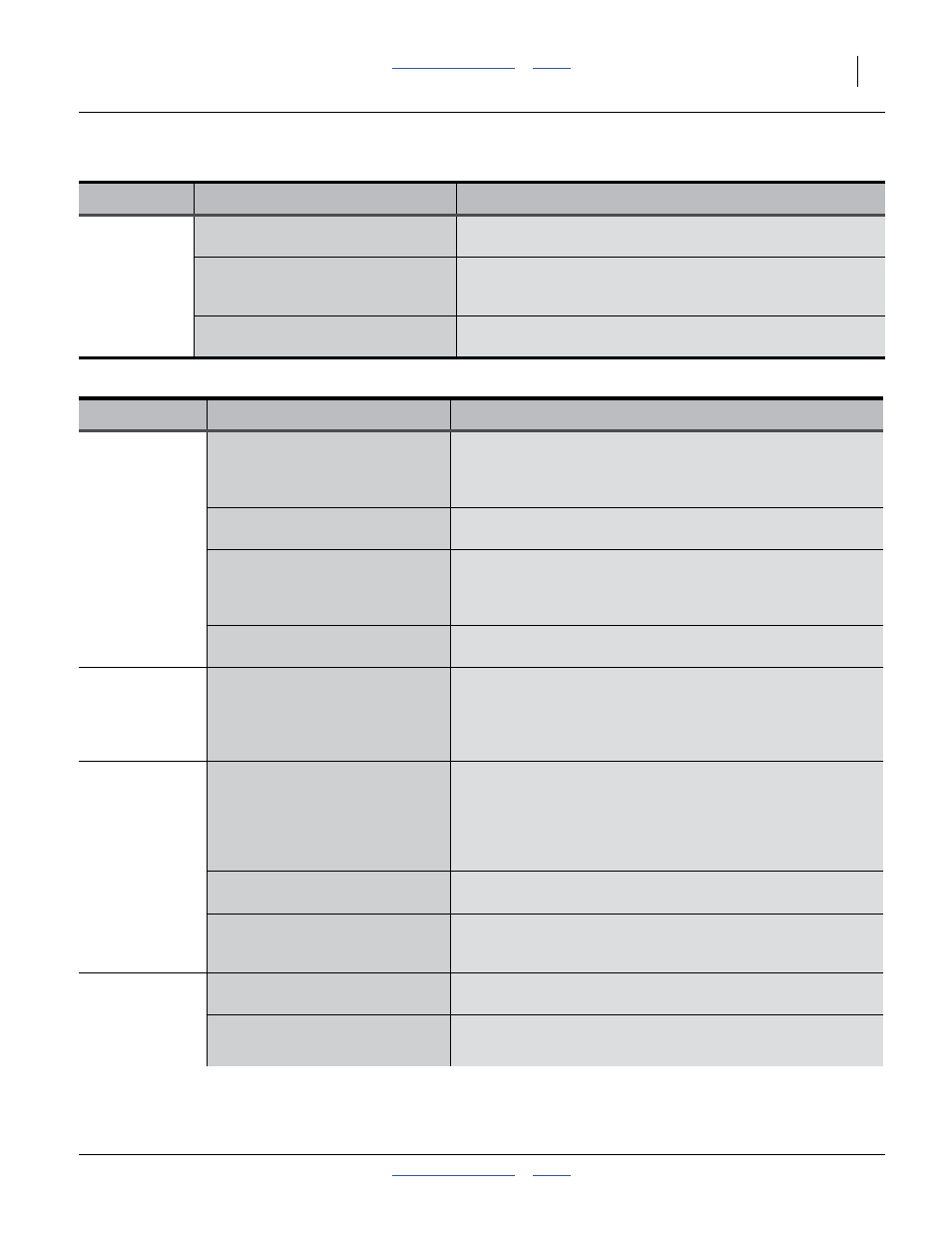

Troubleshooting

83

2013-08-13

401-625M

High

Population,

Single Row

Excess meter pressurization causing

doubles

Check shutter.

Worn seed-drop brush and/or strip

brushes allowing excess seed to

pass

Replace worn brushes.

Incorrect seed disk with higher cell

count.

Install correct disk.

Population Too High

Problem

Cause

Solution

Population Related

Problem

Cause

Solution

Overall

Population

Alarms

False alarms or actual rate errors

due to monitor setup with

incorrect [active] row count or

spacing

When troubleshooting population issues, always first rule out

seed monitor setup. Review planter configuration and monitor

setup.

Incorrect cell count

Replace seed disks with correct disks, or reset rate for current

disks (if within range).

Improper gap on speed sensor.

Check speed sensor on planter for

1

⁄

16

inch to

1

⁄

8

inch

(1.6 to 3.2 mm) gap from wheel. Improper gap can cause

erratic speed signal causing monitor to falsely report improper

planting rate.

Incorrect speed sensor constant

Perform speed calibration per DICKEY-john

®

monitor

manual.

Low

Population

Bands Just

After Turns

Insufficient oil to fan - meter

pressures low - seeds falling from

disks.

Perform end-of-pass marker and lift operations separately. If

already performing separately, reduce marker speed, and/or

list more gradually.

Mismatch

Between

Reported and

Furrow

Population

Small seeds (example milo) are

not reliably sensed in the seed

tube

Run with rain covers in place to minimize ambient light

intrusion. Use the population adjustment factor in the

DICKEY-john

®

monitor system to compensate for missed

seeds. For example, change the DICKEY-john

®

Population

Adjustment values from 100% to 130% or 140% as needed.

Remember to set this back to 100% for large seeds.

Seed tube sensor is not counting

all seeds

Clean the seed tube of graphite and dust buildup with long

narrow seed tube brush. Replace sensors that malfunction.

Seeds / revolution value in the

DICKEY-john

®

setup does not

match the disk cell count.

Correct the value in a setup screen or install the correct cell

count disc.

Unable to

adjust air

pressure low

enough.

Lower limit reached in

DICKEY-john

®

software.

At User Level 2, reduce the controlled air lower limit in the

software.

Fan speed too high, vane rotated

to maximum.

Reduce the fan speed.