Setting material rates, Planting rate, Ground drive planting rate – Great Plains YP1625A Operator Manual User Manual

Page 53: Drive speed range sprockets, Transmission sprockets

Great Plains Manufacturing, Inc.

Adjustments

49

2013-08-13

401-625M

Setting Material Rates

Planting Rate

Adjusting the planting rate requires the following:

1.

setting seed rate:

For ground-drive planters:

adjusting drive speed Range sprockets, and

adjusting Transmission sprockets,

For hydraulic drive planters, setting monitor and

drive control channel,

2.

preparing seed meters, including disks, shutters and

meter pressurization,

3.

checking tire pressure.

4.

checking planting rate.

Ground Drive Planting Rate

Wing Rate Mismatch Risk:

There are separate left and right contact drives. Each drives

one wing. Sprockets must be set identically on both side, per

decals on each drive.

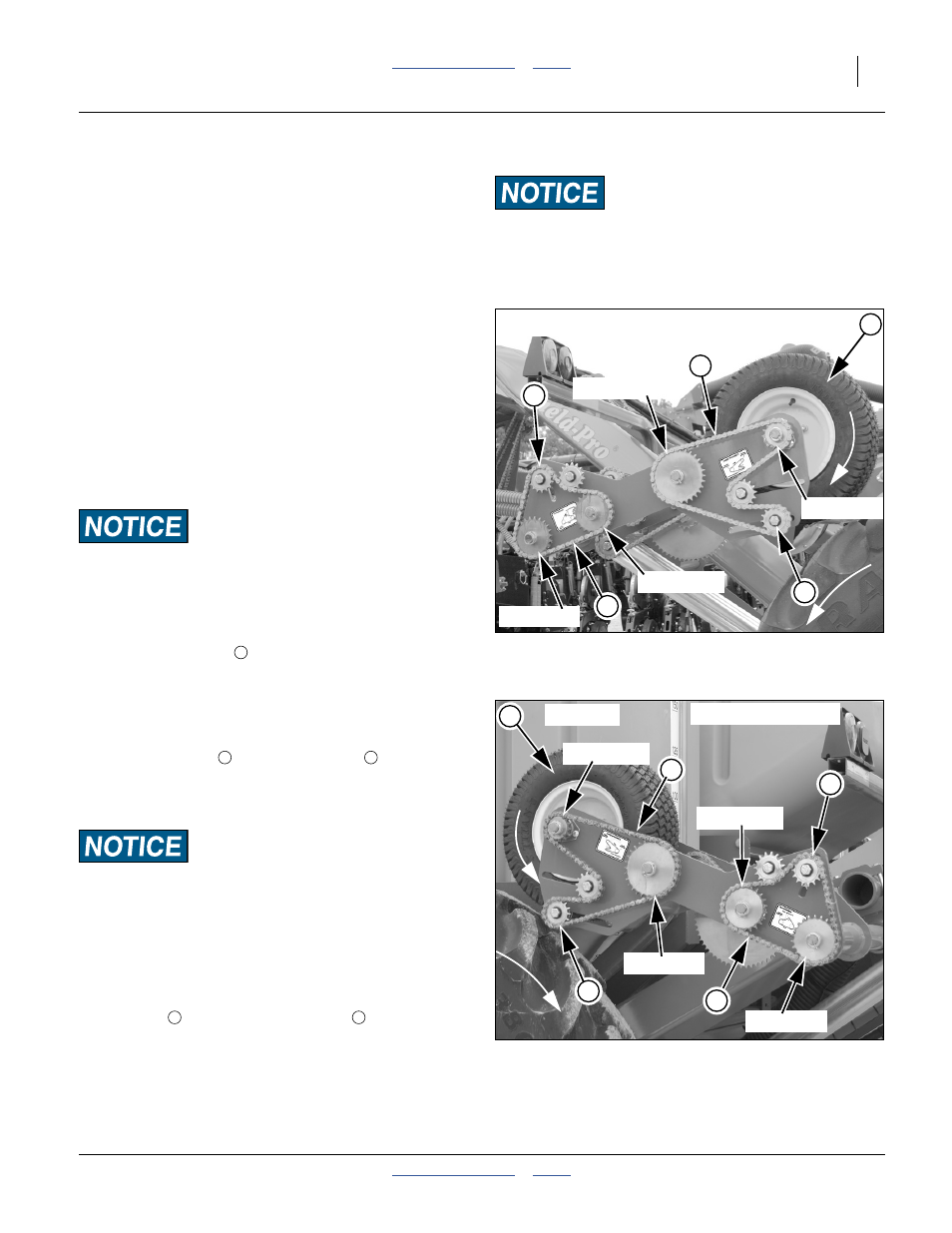

Refer to Figure 56 and Figure 57

Note: Contact wheels

turn in opposite direction from

main ground tires.

Drive Speed Range Sprockets

Select Range sprocket pairing for your seed and rate

from the Seed Rate manual.

Loosen Range idler

and remove chain

. Remove

retaining pins from shafts and install speed Range

sprockets called for in chart. Additional sprockets are on

storage towers behind the reversing drive plate.

Population Target and Wing Rate Risk:

Make sure the correct sprockets have been installed in the

DRIVING and DRIVEN locations.

Reroute chain over sprockets and idlers as shown.

Transmission Sprockets

Select Transmission sprocket pairing for your seed and

rate from the charts in the Seed Rate manual.

Loosen idler

and remove drive chain

. Remove

lynch pins from shafts. Install sprockets per chart.

Reroute drive chain over sprockets and idlers as shown.

Move idlers into chains for

1

⁄

4

inch (6 mm) slack in the

longest spans. Tighten idlers and re-install lynch pins.

Store and pin removed sprockets on storage towers.

Figure 56

Left Contact Drive

29745

Population Target Risk:

Tire pressure matters for both ground and hydraulic drive.

Incorrect tire pressure causes incorrect ground speed readout.

On ground drive, incorrect pressure causes incorrect or

inconsistent seed metering.

1

3

4

2

DRIVING

DRIVEN

RANGE

TRANSMISSION

DRIVEN

DRIVING

5

1

Figure 57

Right Contact Drive

29746

1

3

4

2

DRIVING

DRIVEN

RANGE

TRANSMISSION

DRIVEN

DRIVING

5

2

3

4

5