Great Plains YP1625A Operator Manual User Manual

Page 91

Great Plains Manufacturing, Inc.

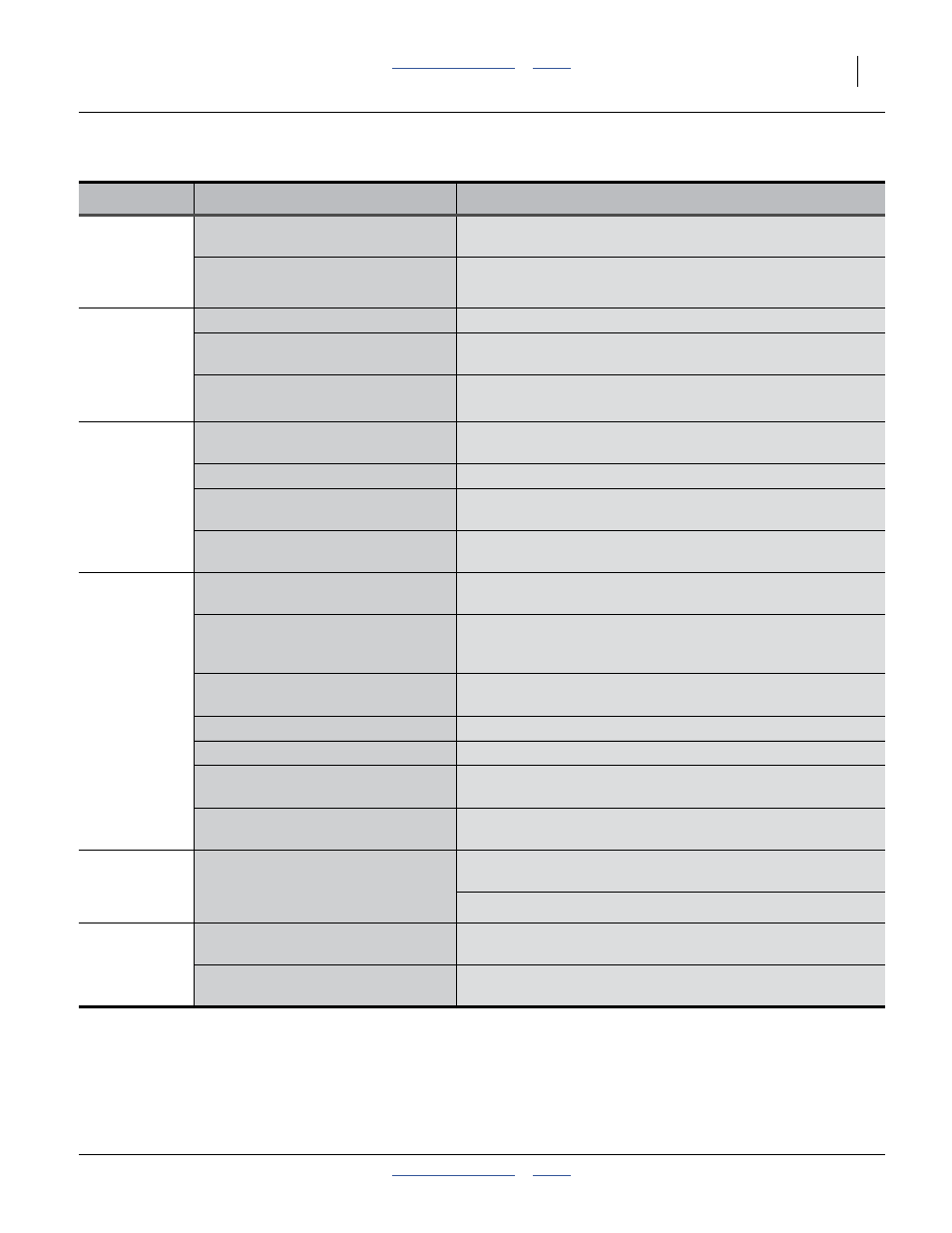

Troubleshooting

87

2013-08-13

401-625M

Seed

blowing out

of bulk box

door area

Fan too fast.

Slow down fan. If already at 3000 rpm, reset fan to 3800 rpm

and use fan butterfly valve to reduce airflow.

Seal from airbox to hopper damaged

or not adjusted.

Inspect and adjust seal. Seal should be intact, and compress

to about

1

⁄

2

in (13mm) under seed container.

Air lines

plugging

between air

box and Y

splitters

Fan too slow.

Speed up fan.

Air leaks between air box manifold

and splitters

Check for leaks and correct as needed.

Improper hose routing, sags or kinks With planter unfolded, hoses should for a gentle “S” shape

through the holders, with no deep sags.

Air lines

plugging

between

Y-tube and

meter

Sag or kink in air hose.

Check air tube placement in tube mount weldment. If correct,

shorten any hose that has stretched due to age.

Meter is shut off but Y-tube is open.

Shut off Y-tube.

Air tube assembly not positioned on

correct tab.

Move assembly to properly position Y-tubes over row meters.

Sag in air hose due to incorrect

frame height

Raise or lower the tongue so center portion of frame is level

with gauge wheel area.

Hydraulic

marker

functioning

improperly,

or not at all

Marker/Fold switch set to Fold.

CFM Switch must be set to “Marker”. Set tractor remote

circuit to Neutral or Float before operating switch.

Marker/Aux valve set to Aux

On a planter with optional Auxiliary Hydraulics, selector valve

must be set to Marker for markers to function. Set tractor

remote circuit to Neutral or Float before changing valve.

Air or oil leaks in hose fittings or

connections.

Check all hose fittings and connections for air or oil leaks.

Low tractor hydraulic oil level.

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners.

Check all bolts and fasteners.

Needle valve plugged.

Open needle valve, cycle markers slowly and reset needle

valve, refer to page 56.

Needle valve(s) in sequence valve

plugged.

Open needle valves, cycle markers slowly and reset needle

valves, refer to page 56.

Marker disk

does not

mark

Marker folding linkage does not have

enough slack to allow marker disk to

drop into field depressions.

Maximum down float should be limited by the slot at the rod

end of the marker cylinder, refer to page 56.

Reverse marker disk to pull or throw dirt.

Auxiliary

Hydraulics

Inoperative

Marker/Fold switch set to Fold

CFM Switch must be set to “Marker” for Aux to function. Set

tractor remote circuit to Neutral or Float before switching.

Marker/Aux valve set to Marker

Selector valve must be set to Aux. Set tractor remote circuit

to Neutral or Float before changing valve.

General Troubleshooting

Problem

Cause

Solution