2 brake troubleshooting – Great Plains CDA600 Operator Manual User Manual

Page 86

Centurion CDA600

270-600M-ENG

84

2013-06-14

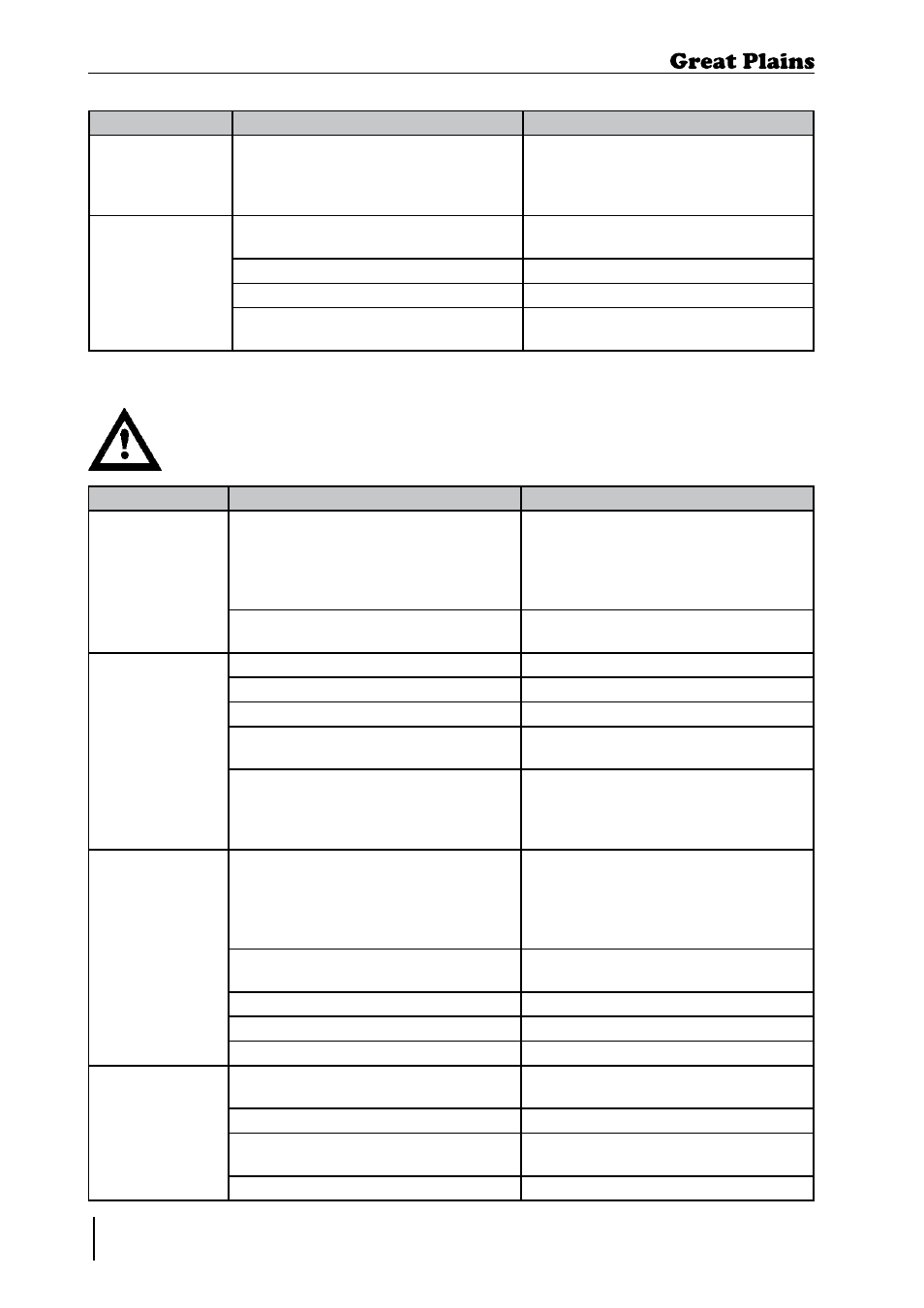

6. Faults and Remedies

Problem

Causes

Solutions

Front of openers

dropping too low in

hard or minimum-

till conditions

Disc Coulters set too deep

Raise opener frame.

Hydraulic

boutmarker

functioning

improperly

Air or oil leaks in hose fittings or

connections.

Check all hose fittings and connections

for air or oil leaks.

Low tractor hydraulic oil level.

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners.

Check all bolts and fasteners.

Disc orientation not ideal for conditions

Reverse boutmarker disc to pull or

throw dirt.

6.2 Brake Troubleshooting

Problem

Causes

Solutions

Smoke or odd

burning odour

from axle area

Overheated brakes, typically on long

steep hills

Stop immediately. Wait for brakes to

cool completely. Moderate downhill

speed by using lower gear and frequent

full stops. Check brake components for

heat distortion.

New brakes may exhibit slight smoking

or odours until linings seat on drums.

Check brakes if problem persists, or

braking action is insufficient.

Braking

insufficient,

one wheel

Tyre under-inflated.

Inflate all tyres to specification.

Worn brake linings and/or drum

Service brakes.

Worn or leaking brake cylinder

Rebuild or replace cylinder.

Grease or oil on linings

Correct problem causing contamination.

Service brakes.

Brake adjuster not adjusting

Ice or dried mud can freeze mechanism.

Check for damage seizing movement.

Check for worn and inoperative pawl, or

weak/damaged/missing pawl spring.

Braking

insufficient,

all wheels

Air in drill brake lines

Check for loose fittings. Check for

damaged fittings and lines. Check for

damage or worn operating components.

Correct source of leak. Recharge and

bleed system.

Air/Hydraulic system: damaged

diaphragm in booster chamber

Replace booster.

Air/Hydraulic system: leaks in air system Repair leaks.

Air/Hydraulic system: clogged filters

Clean filters.

Air/Hydraulic system: valve open

Close dump valve.

Braking

insufficient,

all wheels (cont.)

Hydraulic/Hydraulic system: air in brake

line from tractor

Bleed and recharge brake line.

Brake linings and/or drums worn

Service brakes.

Brake linings replaced with un-approved

parts having inadequate friction rating

Replace shoes with approved parts.

Pressure supplied by tractor insufficient

55 kPa (80 psi) minimum for air system.

Brake and hub maintenance and

servicing should be carried out by

an authorised Great Plains dealer.