0 faults and remedies, 16 brakes & wheel hubs, 1 general troubleshooting – Great Plains CDA600 Operator Manual User Manual

Page 83

81

Centurion CDA600

270-600M-ENG

2013-06-14

5.16 Brakes & Wheel

Hubs

Check for hydraulic fluid and air

leaks.

Brake and hub maintenance and

servicing should be carried out by

an authorised Great Plains dealer.

R e f e r t o t h e B r a k e M a i n t e n a n c e

Manual supplied with the machine for

information on servicing brakes (further

information is available from Erentek -

www.erentek.co.uk).

6. Faults and Remedies

6.0 Faults and Remedies

6.1 General Troubleshooting

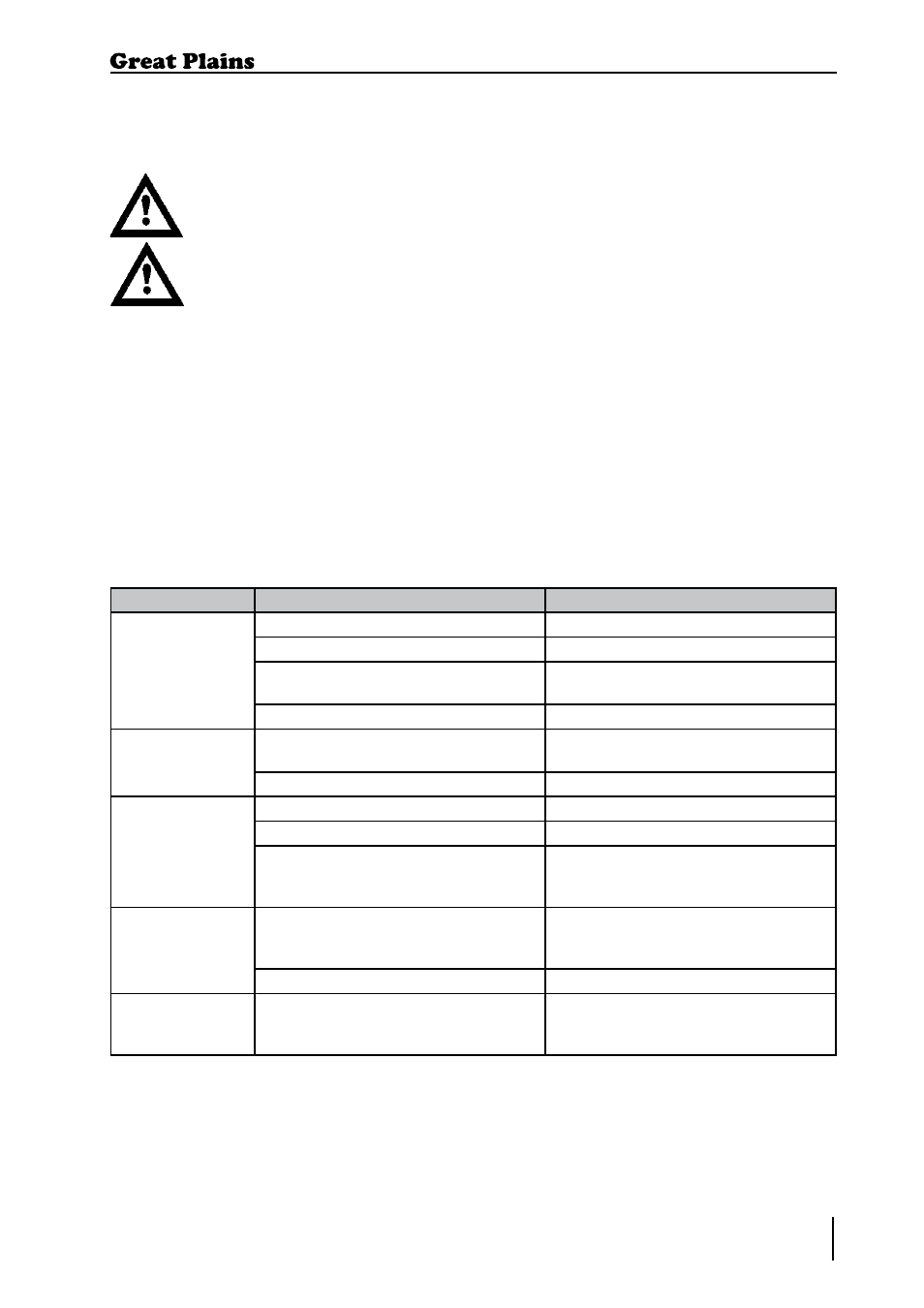

Problem

Causes

Solutions

No material flow

(all rows)

Empty hopper

Load material.

Meter in use clogged

Clean-out meter.

Fan speed too low

Increase fan speed to recommended

range (page 42).

Fan running backward

Reverse fan circuit hoses at hitch.

No material flow

(multiple rows)

Primary seed hose blocked

Check seed hoses for kinks, congealed

materials at low spots, nests and pests.

Tower inlet or turret blocked

Clear blockage.

No material flow

(one or two rows)

Seed tube blocked at row

Inspect and clear seed tube.

Tower port blocked for affected row

Open hopper lid and inspect.

False alarm - seed tube sensor

disconnected or failed

Run monitor self-test. Swap sensor with

a working row to verify failure. Replace

sensor. Adjust sensor sensitivity.

Material is flowing,

but is not detected

by seed monitor

This is normal during the first few

meters/feet of planting, as it takes some

time for material to reach rows.

Lower openers 3m/10ft before planting

is to begin. Monitor does not check for

blockage during first 5 seconds.

Seed monitor disconnected.

Connect seed monitor.

Planting too little

(some rows)

Partial blockage in meter chamber, seed

hoses, towers, seed tubes

Treat as blockage. See “No material

flow (multiple rows)” and “No material

flow (one or two rows)”.