20 calibration – Great Plains CDA600 Operator Manual User Manual

Page 64

Centurion CDA600

270-600M-ENG

62

2013-06-14

4. Adjustment / Operation

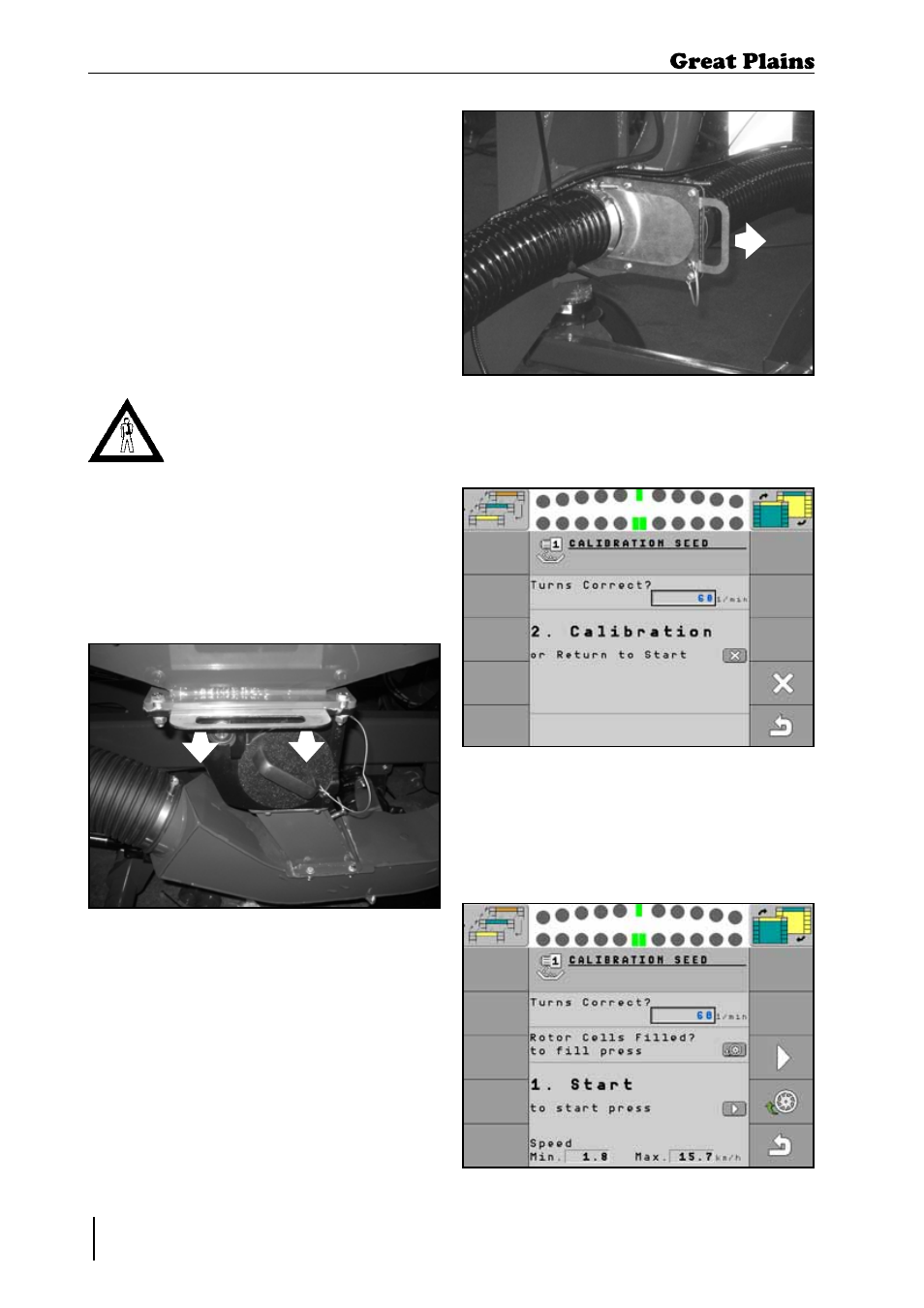

3. Press the calibration key on the control

panel to enter the calibration screen.

4. Set the calibration speed. This can

be selected using the 'return' key and

altered using the knob (or input keys if

using Basic terminal).

4.20 Calibration

The Centurion is a volumetric implement.

For a given metering setup, rates vary

for materials with different density and

granularity. The tables provide a starting

point, but calibration is essential for

accurate application. The seed monitor

reports, and can optionally control, seed

rates. A red press-and-hold calibration

switch is installed on the drill at the rear of

the machine.

Wear goggles and a dust mask

when performing calibration

procedures.

1. Before starting calibration ensure that

the correct metering roller is installed.

2. Open the meter door and move the

calibration diverter to divert seed to the

hose running to the rear of the machine.

Figure 52. Meter door (shown in closed position)

Figure 53. Calibration diverter

Figure 55. Calibration screen

Figure 54. Calibration screen