5 shutdown procedure, 6 routine maintenance, 7 heating and cooling jackets – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 8: 4 start up procedure

SECTION TSM 285

ISSUE

A

PAGE 8 OF 36

3.5 SHUTDOWN PROCEDURE

When shutting the pump down, stop pump, close

both the suction and discharge valves and ensure

that the necessary safety precautions are taken:

- The prime mover power source has been

isolated.

- If installed, pneumatically operated integral

relief valve has been depressurized.

- Flushed product seal auxiliary services have

been isolated and depressurized.

- Pump head and piping have been drained and

purged.

- Before undertaking any work on the pump refer

to sections 4, 5, 6 and 7.

3.6 ROUTINE MAINTENANCE

- Check oil levels regularly.

- Change the oil every 12 months or 3000 operating hours,

whichever is the sooner.

- For lubricant capacities and grades refer to section 8.3.

3.7 HEATING AND COOLING

JACkETS

See Figure 9 and Figure 10.

The Classic+ can be supplied with a jacketed head and casing

for circulation of a heating/cooling media.

The jacketed head and casing ports are strategically positioned

such that the required thermal effect acts on the pumping

chamber.

The pressure rating of the Classic+ series jacketed

head and casing is 3 Bar (50 psi) and this should

not be exceeded without consulting Viking Pump

or your local Viking Pump distributor.

Heating/cooling of the pump head is used to maintain, rather

than increase/decrease the temperature of the pumped media

and should be used as part of a complete system where suction

and discharge lines and vessels are also heated/cooled.

Where heating/cooling devices are employed, the heating/

cooling media should be circulated 15-20 minutes prior to pump

start-up and should be allowed to continue for a similar period

of time after the pump has been shut down. Where an in-line

cleaning cycle is employed as part of the process, then the

heating/cooling media should continue to be circulated during

the cleaning cycle.

3.4 Start Up Procedure

- Check that all piping and associated equipment

are clean and free from debris and that all pipe

connections are secure and leak free.

- For pumps fitted with flushed product seals

check all auxiliary services are in place

and connected and provide sufficient flow

and pressure for flushing purposes, refer to

section 7.0.

- Ensure lubrication is provided for both pump

and drive. The Classic+ is shipped

without oil

as standard and should be filled to the level

of the oil sight glass - refer to section 8.3 for

pump oil capacities and grades.

- If an external relief valve is incorporated in the

system, check that it is set correctly. For start up

purposes, it is considered good practice to set

the relief valve lower than the system design

pressure. On completion of start up, the relief

valve should be reset to the required setting

for the application. The required setting should

never exceed the lower of either the pumps

maximum pressure rating or the system design

pressure. For setting integral relief valves refer

to sections 3.8.1 and 3.8.2.

- Be sure both suction and discharge valves are

fully opened and that pipe work is free from

all obstructions. The Classic+ is a positive

displacement type pump and should therefore

never be operated against a closed valve as this

would result in pressure overload, resulting in

damage to the pump and possibly the system.

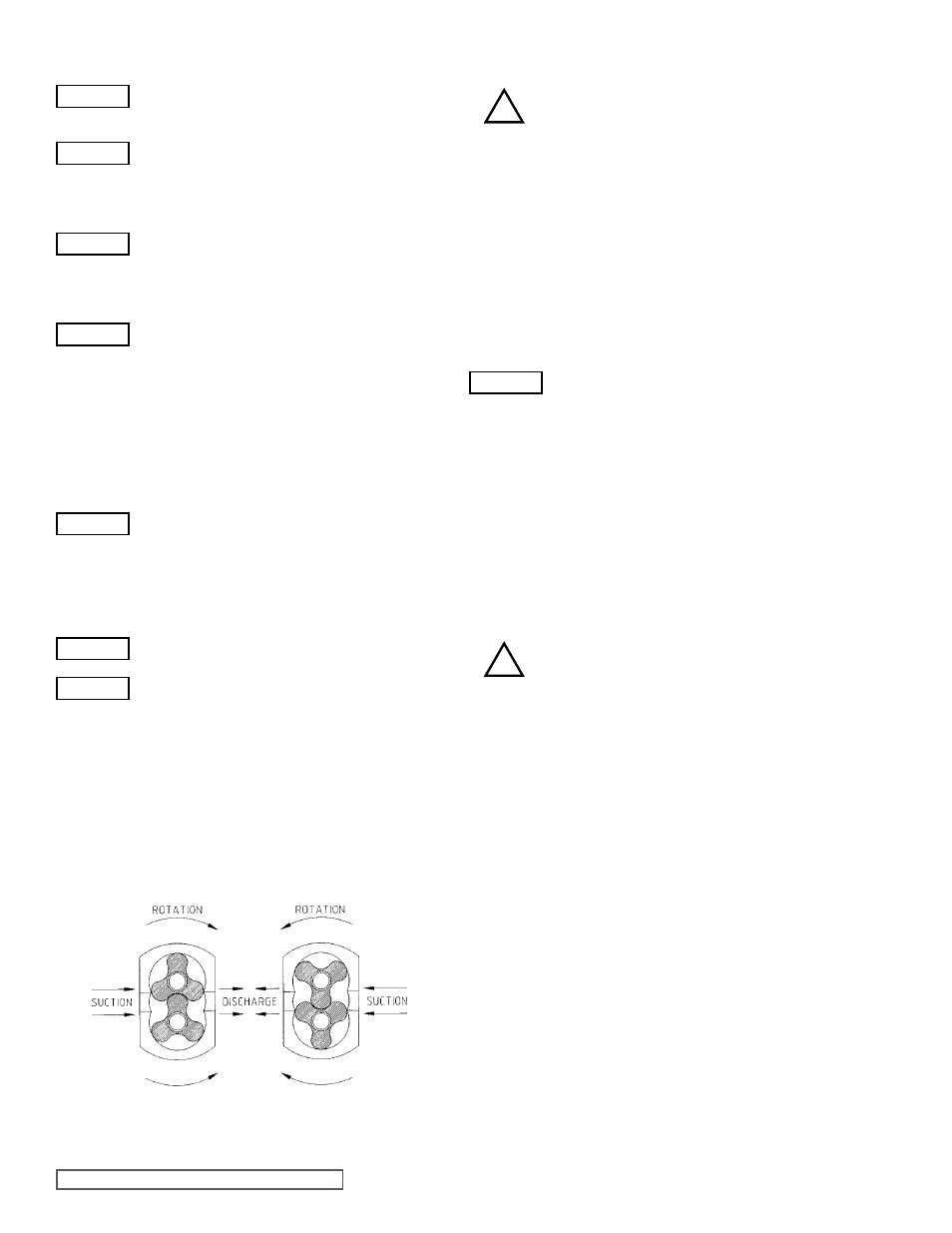

- Make sure that the drive shaft rotation is correct

for the direction of flow required. See Figure 8.

- Be sure product is available in the suction

vessel before starting the pump. This is very

important for pumps fitted with un-flushed

product seals, as these sealing arrangements

must never be allowed to run dry.

- Before beginning operation, it is considered good practice

to momentarily start/stop the pump to check the direction of

rotation and ensure that the pump is free of obstructions.

Once this has been carried out, begin operation keeping a

visual check on suction and discharge pressure gauges and

monitor the pump temperature and absorbed power where

possible.

figure 8

Rotation Against Suction and Discharge

!

WARNING

!

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING