3 lubricants, 4 troubleshooting 8.5 material specifications – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 33

SECTION TSM 285

ISSUE

A

PAGE 33 OF 36

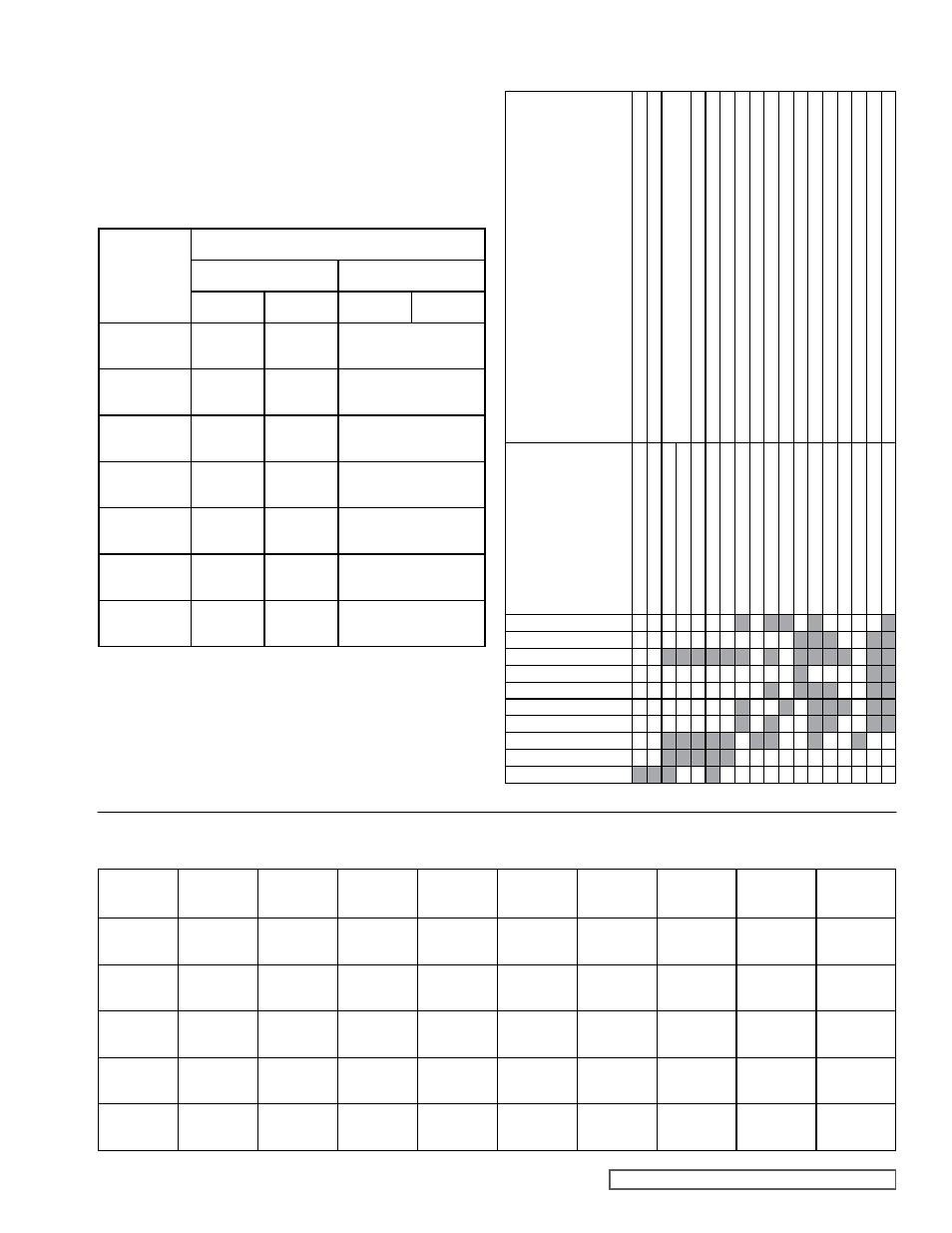

Pump Model

Mounting Attitude with Suction and Discharge ports in:

Horizontal Plane

Vertical Plane

Liters

US Pints

Liters

US Pints

CP10

0.25

0.44

To be advised - Fill to Sight

Glass level (see below)

CP20

0.50

0.88

To be advised - Fill to Sight

Glass level (see below)

CP30

1.00

1.76

To be advised - Fill to Sight

Glass level (see below)

CP40*

(Top Cavity)

0.75

1.32

To be advised - Fill to Sight

Glass level (see below)

CP40*

(Bottom Cavity)

1.75

3.08

To be advised - Fill to Sight

Glass level (see below)

CP50*

(Top Cavity)

0.60

1.05

To be advised - Fill to Sight

Glass level (see below)

CP50*

(Bottom Cavity)

0.80

1.41

To be advised - Fill to Sight

Glass level (see below)

8.3 LUbRICANTS

Gearbox oil recommended for use with Classic+ is an

‘EP (Extreme Pressure) grade gear lube’ for the following

temperature ranges.

EP150 -2 – 0°C (0 – 32°F)

EP220 0 – 30°C (32 - 85°F)

EP320 30°C (85°F) and higher

Approximate lubricant capacities for the Classic+:

* Note: The CP40 and CP50 have two gearbox cavities that

should be subject to the same maintenance program.

Always add oil to the level of the sight glass. The sight glass

must be located in the uppermost position on the side of the

gearbox.

No flow

Irregular flow

Under Capacity

Pump Overheats

Motor Overheats

Excessive Rotor Wear

Excessive Seal Wear

Noise / Vibration

Seizure

Pump Stalls on Startup

Causes

Action

Incorrect Direction of Rotation

Reverse Motor

Pump Not Primed

Expel Gas From Suction Line / Pump Chamber & Prime

Insuf

ficient NPSH

Available

Increase Line Diameter & Static Suction Head. Simplify Suction Line & Reduce Length. Reduce Pump Speed & Product

Temperature

Product

Vaporizing

in

Suction

Line

Air Entering Suction Line

Remake Piping Joints

Gas in Suction Line

Expel Gas From Suction Line / Pump Chamber

Insuf

ficient Static Suction Head

Raise Product Level to Increase Static Suction Head

Product V

iscosity

Too High

Decrease Pump Speed / Increase Product

Temperature

Product V

iscosity

Too Low

Increase Pump Speed / Decrease Product

Temperature

Product

Temperature

Too High

Cool Product / Pumping Chamber

Product

Temperature

Too Low

Heat Product / Pumping Chamber

Unexpected Solids in Product

Clean the System / Fit Strainer on Suction Side of Pump

Discharge Pressure

Too High

Check for Blockages / Simplify Discharge Line

Casing Strained by Piping

Check Pipe

Alignment / Support Piping

Pump Speed

Too High

Decrease Pump Speed

Pump Speed

Too Low

Increase Pump Speed

Seal Flush Inadequate

Increase Seal Flush to Required Pressure / Flow

Bearing /

Timing Gear W

ear

Replace W

orn Components

8.4 TROUbLESHOOTING

8.5 MATERIAL SPECIfICATIONS

Pump

Model

Casing

Front

Cover

Rotors

Rotor

Retainers

Shafts

Shaft

Sleeves

Gearbox

Bearing

Housing

Gearbox

Cover

CP10

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

N/A

Cast Iron

Cast Iron

N/A

CP20

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

N/A

Cast Iron

Cast Iron

N/A

CP30

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

N/A

Cast Iron

Cast Iron

N/A

CP40

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

N/A

Cast Iron

N/A

Mild Steel

CP50

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

316

Stainless Steel

Cast Iron

N/A

Mild Steel