5 cp10 double flushed mechanical seal removal – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 26

SECTION TSM 285

ISSUE

A

PAGE 26 OF 36

- Install lipseals (7.08) and O-rings (7.07) to housing(s)

(7.06).

- Install housing(s) (7.06) to shafts (5.01 and 5.02).

- Install rotary seal cartridges (7.05) to shafts (5.01 and 5.02)

positioning to correct setting distance, see Figure 50 and

tightening screws in rotary seal cartridge assemblies (7.05)

to correct torque, refer to section 8.2.

Note: Access to screws in rotary cartridge seal assemblies

(7.05) is through the flush pipe connections of housing

(7.06).

- Install casing (3.01), O-rings (2.04), rotors (2.01), O-rings

(2.03), rotor retainers (2.02) and head (1.01), refer to sections

4.1.4 (CP10, CP20 and CP30) or 4.2.5 (CP40).

- Secure housing(s) (7.06) to casing (3.01) with screws (7.10)

ensuring correct location onto dowels (7.09).

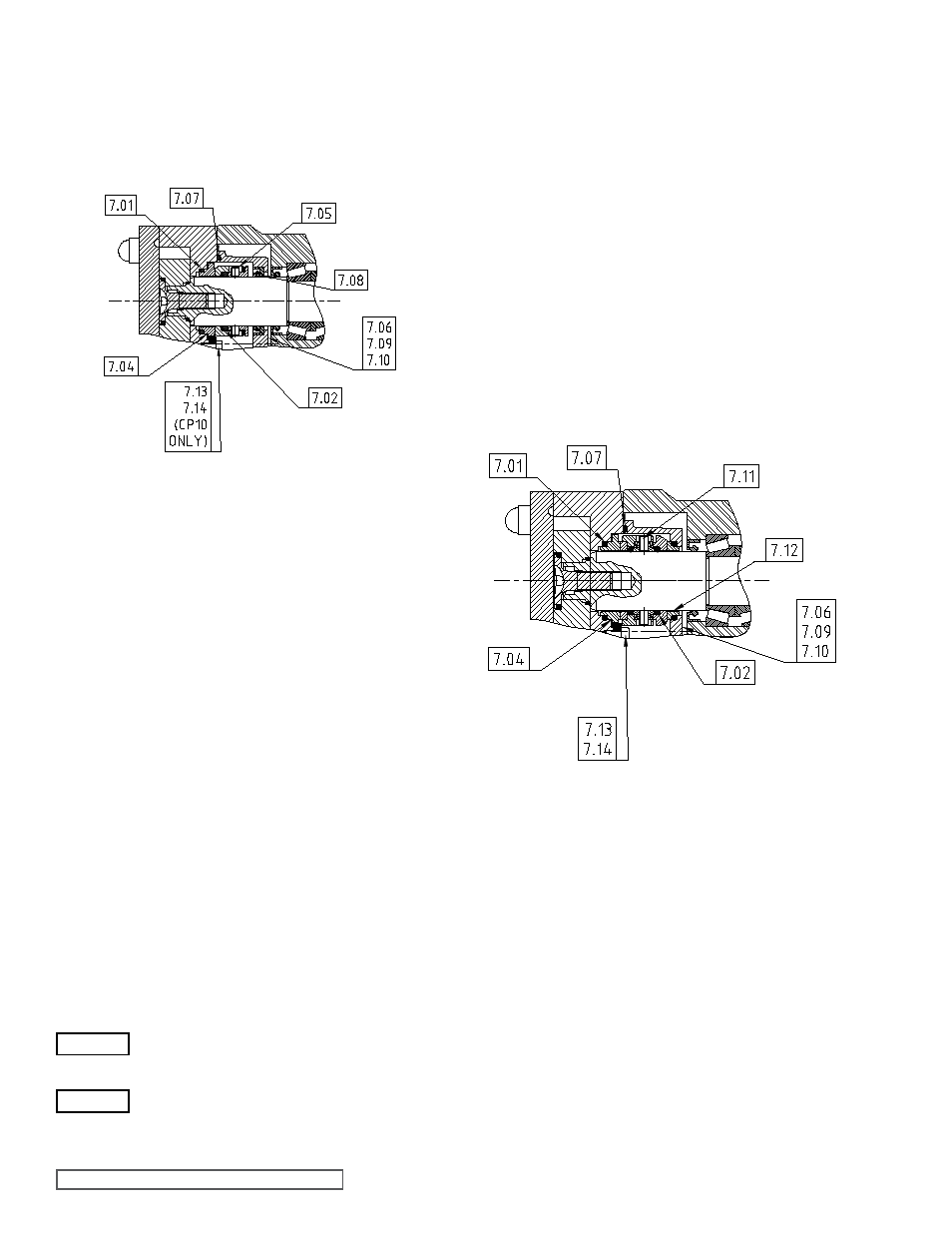

5.2.5 CP10 DOUbLE fLUSHED

MECHANICAL SEAL REMOVAL

Refer to Figure 52.

5.2.3 CP10, CP20, CP30 AND CP40

SINGLE fLUSHED

MECHANICAL SEAL REMOVAL

Refer to Figure 51 for CP10, CP20, CP30 and CP40

- Remove head (1.01), rotor retainers’ (2.02), O-rings (2.03),

rotors (2.01), O-rings (2.04) and casing (3.01), refer to

sections 4.1.2.1 and 4.1.2 (CP10, CP20 or CP30) or 4.2.2.1

(CP40).

- Loosen but do not remove screws in rotary seal cartridge

assemblies (7.05), which secure rotary seal cartridges to

shafts (5.01 and 5.02).

Note: Access to screws in rotary seal cartridge (7.05) is

through the flush pipe connections of housing (7.06).

- Remove rotary seal cartridges (7.05) with O-ring (7.02) from

shafts (5.01 and 5.02).

- Remove housing(s) (7.06) complete with lipseals (7.08) and

O-Ring(s) (7.07) from shafts (5.01 and 5.02).

- Remove lipseals (7.08) and O-ring (s) (7.07) from housing(s)

(7.06).

- Remove stationary seal seats (7.04) and O-rings (7.01) from

casing (3.01).

5.2.4 CP10, CP20, CP30 AND CP40

SINGLE fLUSHED

MECHANICAL SEAL

REPLACEMENT

Refer to Figure 51 for CP10, CP20, CP30 and CP40

- Install O-rings (7.01) to stationary seal seats (7.04).

- Install stationary seal seats (7.04) to casing (3.01) ensuring

correct location of O-rings (7.01).

Note: On CP10 models the stationary seal

seat (7.04) has a location recess which fits

over the anti-rotation washer (7.13).

Note: On CP20, CP30 and CP40 models the

stationary seal seat (7.04) has a triangular

shape, which must locate fully into the casing

(3.01) bore.

- Remove head (1.01), rotor retainers’ (2.02), O-rings (2.03),

rotors (2.01), O-rings (2.04) and casing (3.01), refer to

sections 4.1.1 and 4.1.2.

- Loosen but do not remove screws (7.11), which secure rotary

seal cartridge assemblies (7.11) to shafts (5.01 and 5.02).

Note: Access to screws (7.13) is through the flush pipe

connections of housing (7.06)

- Remove rotary seal cartridges (7.11) with O-rings (7.02) from

shafts (5.01 and 5.02).

- Remove housing (7.06) complete with O-ring (7.07),

stationary seal seats (7.12) and O-rings (7.01) from shafts

(5.01 and 5.02).

- Remove stationary seal seats (7.12), O-rings (7.01) and O-

ring (7.07) from housing (7.06).

- Remove stationary seal seats (7.04) and O-rings (7.01) from

casing (3.01).

figure 52

Double flushed Mechanical Seal

figure 51

Single flushed Mechanical Seal

WARNING

WARNING