2 cp50 casing removal – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 21

SECTION TSM 285

ISSUE

A

PAGE 21 OF 36

- Install product seals; refer to section 5.0 or section 6.0.

- Install casing (3.01) to gearbox (4.01), noting it locates on

dowels (4.03), securing with dome nuts (4.08).

- Install rotors (2.01) with O-rings (2.03 and 2.04) and retainers

(2.02) tightening to correct torque, refer to section 8.2, using

socket tool supplied (not shown).

- Check all rotor clearances, front, rear, top/bottom, sides’ and

mesh, refer to section 8.1, Clearance Chart.

- Install head (1.01) with O-ring (1.02) and secure with nuts

(1.03) tightened to correct torque, refer to section 8.2.

4.3 CP50 PUMPS - DISASSEMbLy

AND ASSEMbLy

4.3.1 CP50 HEAD AND

ROTOR REMOVAL

Follow recommended shutdown procedure - refer

to section 3.5.

- Refer to Figure 39.

- Gradually loosen head retaining dome nuts

(1.03). Care should be taken as there may still

be residual product and pressure in the pump

head and as the dome nuts are loosened, this

will vent to atmosphere.

- Remove dome nuts (1.03).

- Remove head (1.01), using lever slots where necessary and

the head O-ring (1.02).

- Remove rotor caps (2.02) with tool (supplied, not shown).

Note: The tool provided should always be

used to remove the rotor cap. The use of

other tools may damage the rotor cap.

- Remove rotor cap O-rings (2.03).

- Loosen by 2 full turns all screws in rotor retainer (2.05). Once

this is done the retainer may release its grip. If it does not,

loosen further the screws until the assembly becomes free

to remove.

(On some brands of locking device there are two screws that

are different in color (these may also have a washer under the

head). Once these screws are removed tapped holes will be

revealed. By inserting two jackscrews (M8 x 40 setscrews),

into the tapped holes and tightening, the retainer’s grip is

broken. Remove the retainers’ (2.05).

- Remove rotors (2.01) from shafts (5.01 and 5.02).

- Remove O-rings (2.04) and keys (2.06).

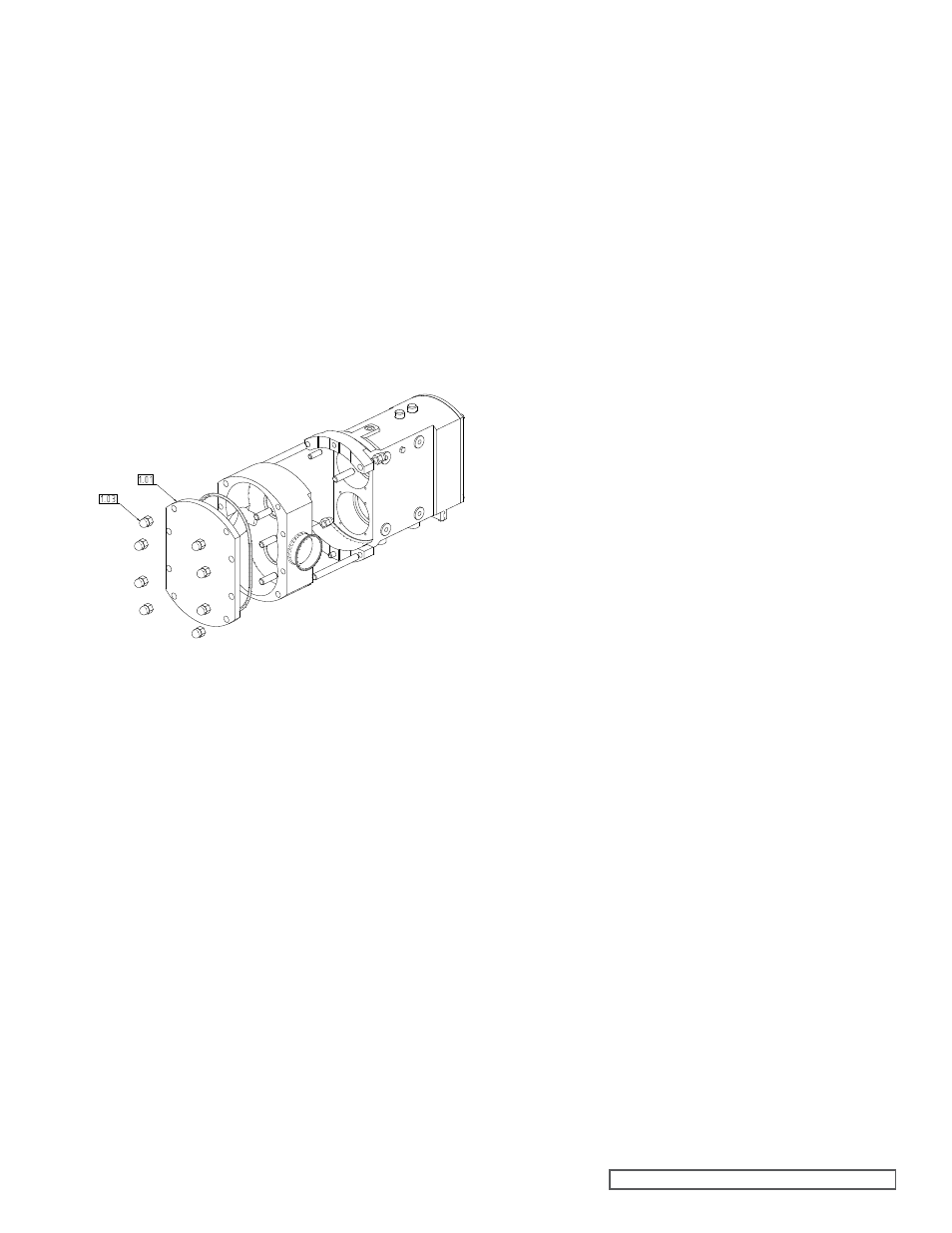

4.3.2 CP50 CASING REMOVAL

Note: Ensure all pipe work is disconnected

before commencing casing removal.

4.3.2.1 CP50 CASING REMOVAL

fOR PUMPS fITTED WITH

SINGLE UN-fLUSHED

MECHANICAL SEALS

AND O-RING SEALS

(After completing 4.3.1)

- Remove dome nuts (4.08).

- Slide casing (3.01) from gearbox (4.01), noting it is located

on dowels (4.03).

Single Un-flushed Mechanical Seals as shown in Figure 40

and see sections 5.3.1 for removal and 5.3.2 for replacement.

Single O-ring Seal for CP50 see Figure 41 and see section

6.3.1 for removal and replacement.

- Remove O-ring seal (7.04) from casing (3.01).

- Slide casing (3.01) from gearbox (4.01) noting it is located on

dowels (4.03).

4.3.2.2 CP50 CASING REMOVAL

fOR PUMPS fITTED

WITH SINGLE fLUSHED

AND DOUbLE fLUSHED

MECHANICAL SEALS

- Refer to Figure 42 for Single flushed mechanical seal for

CP50.

- Refer to Figure 43 for Double flushed mechanical seal for

CP50.

- Prior to removal of casing (3.01), remove seal housing nuts

(7.18) from studs (7.17) and separate housing (7.06) from

casing (3.01).

- Remove dome nuts (4.08).

- Slide casing from bearing housing (4.01), noting it is located

on dowels (4.03).

figure 39

Head and Rotor Components