Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 15

SECTION TSM 285

ISSUE

A

PAGE 15 OF 36

Before starting disassembly of the gearbox remove product

seals; refer to section 5.0 for Mechanical Seals, or section 6.0

for O-ring seals.

The following procedure describes complete disassembly of

the gearbox.

- Refer to Figure 22 for CP10; Refer to Figure 33 for CP20 and

CP30.

- Remove guard (5.06).

- Remove drive key (6.12).

- Remove oil drain plug (6.09) and breather (6.10), drain oil into

suitable container and retain if later inspection is required.

- Remove screws (6.11) and separate gearbox cover (6.00)

from bearing housing (4.01). The gearbox cover (6.00) is

located on dowels (6.06)

Note: The bearing housing (4.01) is provided with two

jacking holes (tapped M8 on CP10; M10 on CP20; M12 on

CP30), which can be used to separate the gearbox cover

(6.00) from the bearing housing (4.01).

- Remove gasket (6.05) from gearbox cover (6.00) or bearing

housing (4.01) depending upon which part the gasket is

adhered to.

- Remove oil seal (6.03) and blanking cap (6.04) from gearbox

cover (6.00).

- Remove retaining rings (6.01) from gearbox cover (6.00) and

press out bearing outer rings (6.02).

- Remove bearing inner ring (6.02) from shafts (5.01 and 5.02).

- CP10 & CP20 Pumps Only - Remove lock nuts (5.12) and

tab washers’ (5.11).

- CP30 Pumps Only – Loosen locking screws from and lock

nuts (5.12).

- Remove timing gears (5.09) and gear keys (5.10).

- CP10 Pumps Only - Remove shims (5.08) and spacers

(5.16), keep shims and spacers in sets and identify position.

- CP30 Pumps Only - Remove shims (5.08) in sets and

identify position.

- Remove screws (5.07) and retainers (5.06) from bearing

housing (4.01).

- Remove shafts (5.01 and 5.02) from bearing housing (4.01)

Shafts (5.01 and 5.02) will be complete with bearings (5.05)

and shims (5.04), keep shims in sets and identify position.

- Remove oil seals (5.03) from bearing housing (4.01).

- Remove bearing cups (5.05) and any associated shims

(5.04) from bearing housing (4.01), keep bearing cups (5.05)

and shims (5.04) in sets and identify position.

- Remove bearing cones (5.05) from shafts (5.01 and 5.02).

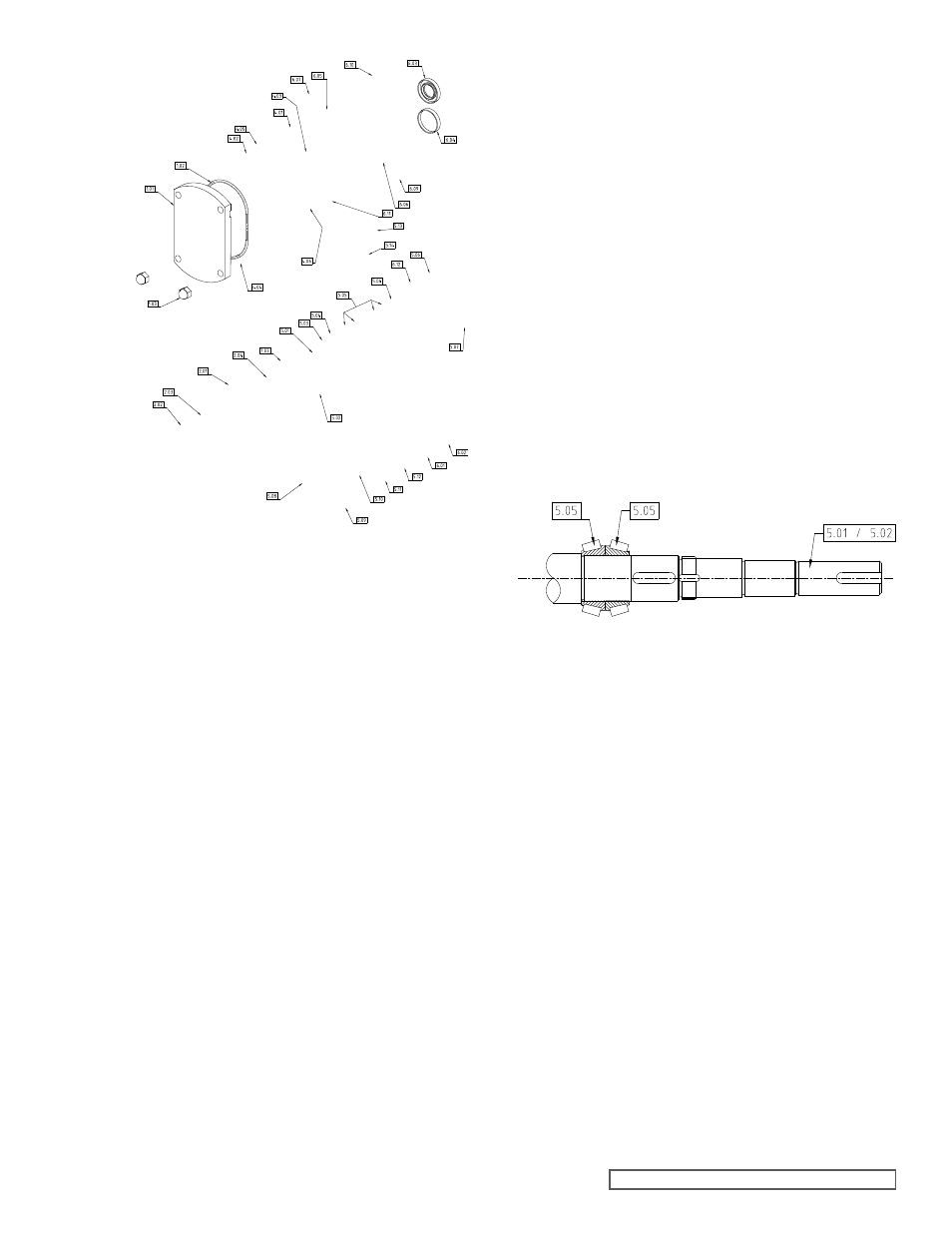

4.1.4 CP10, CP20 AND CP30

GEARbOX ASSEMbLy

Refer to Figure 22 for CP10 or Figure 23 for CP20 and CP30.

- Install bearing cones (5.05) to shafts (5.01 and 5.02) ensuring

they locate against shaft shoulder. The cones are installed

as shown in Figure 24.

- Install two bearing cups (5.05) to bearing housing (4.01).

- Install shafts (5.01 and 5.02) in bearing housing (4.01).

- Install remaining bearing cups (5.05), shims (5.04) to nominal

value of 0.60mm (0.024”), retainers (5.06) and secure with

screws (5.07) tightened to correct torque refer to section

8.2.

- Using a torque wrench, check the rolling torque of each

shaft assembly, referring to section 8.2. If necessary, adjust

amount of shim (5.04), either by adding shim (5.04) to

increase rolling torque or removing shim (5.04) to decrease

rolling torque, until correct rolling torque has been achieved.

If shim (5.04) is adjusted ensure screws (5.07) are tightened

to correct torque before final check of rolling torque.

- Install rotors (2.01) on to shafts (5.01 and 5.02) with rotor

retainers (2.02).

Note: The socket tool (not shown) should

always be used, the use of other tools may

damage the retainer.

- Using a depth micrometer or similar device measure any

difference (X) in rotor front face alignment, see Figure 25. If

a difference is found move shims (5.04) of thickness equal to

the difference (X) from beneath the forward rotor’s bearing

retainer (5.06) and reposition under the front bearing (5.05)

cup.

figure 24

Installation of bearing cones onto shafts

Figure 23

CP20 and CP30

Component Parts